Prescriptive Checklist for the

2018 Washington State Energy Code

Chapter 51-11R WAC

State Building Code Adoption and Amendment of the 2018 Edition

of the International Energy Conservation Code, Residential Provisions

Washington State Energy Code – Residential Provisions

Updated December 2020

© 2020 Washington State University Energy Program

This publication contains material written and produced for public distribution. Permission to copy or

disseminate all or part of this material is granted, provided that the copies are not made or distributed

for commercial advantage and that they are referenced by title with credit to the

Washington State University Energy Program.

WSUEEP13-060 • revised December 2020

Prescriptive Checklist for the 2018 Washington State Energy Code - Residential 2

This prescriptive checklist cites 2018 Washington State Energy Code - Residential (WSEC-R) items

that apply to most residential new construction projects. This checklist is not a substitute for the

energy code itself, nor is it a list of comprehensive energy code requirements. More resources

about the energy code are available on the Washington State University Energy Program website.

☐ R103.2 Information on Construction Documents

Include details in construction documents regarding insulation materials and their R-values;

fenestration U-factors and SHGCs; area-weighted U-factor and SHGC calculations; mechanical

system design criteria; mechanical and service water heating system and equipment types, sizes

and efficiencies; equipment and systems controls; duct sealing, duct and pipe insulation and

location; and air sealing details.

☐ R103.3.1 Approval of Construction Documents

One set of construction documents so reviewed shall be retained by the code official. The other

set shall be returned to the applicant, kept at the site of work and shall be open to inspection by

the code official or a duly authorized representative.

☐ R104.1 General

Construction or work for which a permit is required shall be subject to inspection by the code

official or his or her designated agent, and such construction or work shall remain visible and able

to be accessed for inspection purposes until approved. It shall be the duty of the permit applicant

to cause the work to remain visible and able to be accessed for inspection purposes. Neither the

code official nor the jurisdiction shall be liable for expense entailed in the removal or replacement

of any material, product, system or building component required to allow inspection to validate

compliance with this code.

☐ R104.2.2.1 Wall Insulation Inspection

The building official, upon notification, shall make a wall insulation inspection in addition to those

inspections required in Section R109 of the International Residential Code. This inspection shall be

made after all wall and cavity insulation is in place and prior to cover.

☐ R302.2 Design Conditions for Sizing HVAC

The heating or cooling outdoor design temperatures shall be selected from Appendix C, RE-95.

Useful Links: Air Conditioning Contractors of America

NEEA HVAC Sizing Tool

☐ R303.1.1 Insulation Certification

The insulation installers shall provide a certification listing the type, manufacturer and R-value of

insulation installed in each element of the building thermal envelope. For blown or sprayed

insulation (fiberglass and cellulose), the initial installed thickness, settled thickness, settled R-value,

Prescriptive Checklist for the 2018 Washington State Energy Code - Residential 3

installed density, coverage area and number of bags installed shall be listed on the certification. For

sprayed polyurethane foam (SPF) insulation, the installed thickness of the areas covered and R-value

of installed thickness shall be listed on the certification. For insulated siding, the R-value shall be

labeled on the product’s package and shall be listed on the certification. The insulation installer shall

sign, date and post the certification in a conspicuous location on the job site.

Exception: For roof insulation installed above the deck, the R-value shall be labeled as

required by the material standards specified in Table 1508.2 of the International Building

Code or Table R906.2 of the International Residential Code.

Insulation Certificate for Residential New Construction

Useful Links: North American Insulation Manufacturers Association

Spray Polyurethane Foam Alliance

Foam Sheathing Coalition

☐ R303.1.1.1 Insulation Markers

The thickness of blown-in or sprayed roof/ceiling insulation

(fiberglass or cellulose) shall be written in inches (mm) on

markers that are installed at least one for every 300 square

feet (28 m

2

) throughout the attic space. The markers shall be

affixed to the trusses or joists and marked with the minimum

initial installed thickness with numbers a minimum of 1 inch

(25 mm) in height.

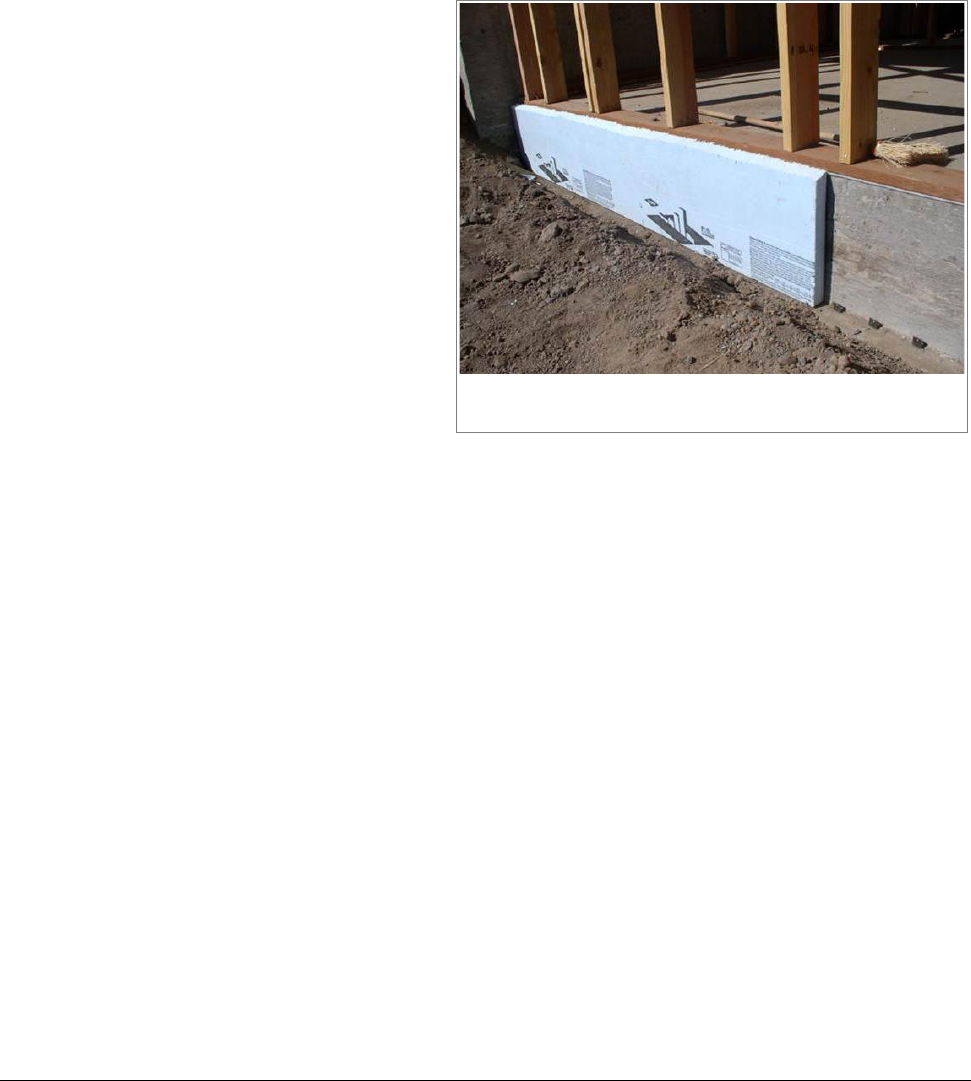

☐ R303.2.1 Protection of Exposed Foundation Insulation -

above grade and 6” below grade

Insulation applied to the exterior of basement walls,

crawlspace walls and the perimeter of slab-on-grade floors

shall have a rigid, opaque and weather-resistant protective

covering to prevent the degradation of the insulation’s

thermal performance.

☐ R401.3 Certificate

A permanent certificate shall be completed by the builder or

other approved party and posted on a wall in the space

where the furnace is located, a utility room, or an approved location inside the building.

2018 Compliance Certificate

2018 Compliance Certificate Instructions

R303.1.3 Insulation Markers

Insulation marker installed in attic. Make

sure the marker is applicable to the type

of insulation installed (fiberglass,

cellulose, etc.)

Prescriptive Checklist for the 2018 Washington State Energy Code - Residential 4

☐ Table 402.1.1 Footnote “d” Slab R-Value

R-10 continuous insulation (CI) is required under

heated slab on grade floors. See R402.2.9.1.

☐ Table 402.1.1 Footnote “e” Ceiling R-Value

For single rafter or joist-vaulted ceilings, the

insulation may be reduced to R-38 if the full

insulation depth extends over the top plate of

the exterior wall.

Table R402.1.1 Footnote “d” Slab R-Value

R-10 fully insulated slab for heated slab-on-grade floors

Prescriptive Checklist for the 2018 Washington State Energy Code - Residential 5

☐ Table 402.1.1 Footnote “f” Existing Slab R-

Value

R-7.5 CI installed over an existing slab is

deemed equivalent to the required perimeter

slab insulation when applied to existing slabs

complying with Section R503.1.1. If foam

plastic is used, it shall meet requirements for

thermal barriers protecting foam plastics.

☐ Table 402.1.1 Footnote “h” Intermediate

Framing

Intermediate framing denotes framing and

insulation as described in Section A103.2.2

including standard framing 16 inches on center,

78% of wall cavity insulated and headers

insulated with a minimum of R-10 insulation.

☐ R402.2.1 Ceilings with Attic Spaces

Where Section R402.1.1 would require R-49 in

the ceiling, installing R-38 over 100% of the

ceiling area requiring insulation shall be

deemed to satisfy the requirement for R-49

wherever the full height of uncompressed R-38

insulation extends over the wall top plate at the

eaves. This reduction shall not apply to the U-

factor alternative approach in Section R402.1.3

and total UA alternative in Section R402.1.4.

R402.2.1 Ceilings with Attic Spaces

You can reduce ceiling insulation R-value to 38 if you

have R-38 extending to the exterior wall line

Table 402.1.1 Footnote “h” Intermediate Framing

“INT” walls require R-10 insulated headers

Table 402.1.1 Footnote “f” Existing Slab Insulation

R-7.5 CI installed over an existing slab is deemed

equivalent to the required perimeter slab insulation

Prescriptive Checklist for the 2018 Washington State Energy Code - Residential 6

☐ R402.2.1.1 Loose Fill Insulation in Attic Spaces

Open-blown or poured loose fill insulation may be used in attic

spaces where the slope of the ceiling is not more than 3 feet in

12 and there is at least 30 inches of clear distance from the top

of the bottom chord of the truss or ceiling joist to the

underside of the sheathing at the roof ridge.

☐ R402.2.3 Eave Baffle

For air permeable insulation in vented attics, a baffle shall be

installed adjacent to soffit and eave vents.

☐ R402.2.4 Access Hatches and Doors

Access doors from conditioned spaces to unconditioned spaces

(e.g., attics and crawl spaces) shall be weather stripped and

insulated to a level equivalent to the insulation on the

surrounding surfaces.

☐ R402.2.7 Floors

Floor framing cavity insulation shall be installed to maintain

permanent contact with the underside of the subfloor decking.

Insulation supports shall be installed so spacing is no more than

24 inches on center. Foundation vents shall be placed so that the

top of the vent is below the lower surface of the floor insulation.

☐ R402.2.7 Floors Exception

The floor framing cavity insulation shall be permitted to be in

contact with the topside of sheathing or CI installed on the bottom side of floor framing where

combined with insulation that meets or exceeds the minimum Wood Frame R-value in Table

R402.1.1 and extends from the bottom to the top of all perimeter floor framing members.

☐ R402.2.7 Floors Exception

When foundation vents are not placed so that the top of the vent is below the lower surface of the

floor insulation, a permanently attached baffle shall be installed at an angle of 30° from horizontal,

to divert air flow below the lower surface of the floor insulation.

☐ R402.2.7 Floors Exception

Substantial contact with the surface being insulated is not required in enclosed floor/ceiling

assemblies containing ducts where full R value insulation is installed between the duct and the

exterior surface.

R402.2.3 Eave Baffle

Baffle at eave vent. Minimum 1”

unobstructed air space required

R402.2.4 Access Hatches and Doors

Insulated crawl space access. The same

method applies to attic access hatches

Prescriptive Checklist for the 2018 Washington State Energy Code - Residential 7

R402.2.7 Floors

Floor insulation installed with contact to the underside of the floor decking. Note the inset stapled twine.

Prescriptive Checklist for the 2018 Washington State Energy Code - Residential 8

R402.2.7 Floors Exception

Baffle at rim joist vent. The same application is needed for joists hung from the

mudsill at a foundation vent location.

R402.2.7 Floors Exception

Exception for substantial contact with the surface being insulated in a floor/ceiling assembly. It is imperative

that the rim joist be caulked and sealed to minimize air infiltration.

Prescriptive Checklist for the 2018 Washington State Energy Code - Residential 9

☐ R402.2.8 Basement Walls

Below-grade exterior wall insulation used on the exterior (cold) side of the wall shall extend from

the top of the below-grade wall to the top of the footing and shall be approved for below-grade

use. Above-grade insulation shall be protected. Insulation used on the interior (warm) side of the

wall shall extend from the top of the below-grade wall to the below-grade floor level and shall

include R-5 rigid board providing a thermal break between the concrete wall and the slab.

☐ R402.2.9 Slab-on-Grade Floors

The minimum thermal resistance (R-value)

of the insulation around the perimeter of

unheated or heated slab-on-grade floors

shall be as specified in Table R402.1.1. The

insulation shall be placed on the outside of

the foundation or on the inside of the

foundation wall. The insulation shall extend

downward from the top of the slab for a

minimum distance as shown in the table or

to the top of the footing, whichever is less,

or downward to at least the bottom of the

slab and then horizontally to the interior or

exterior for the total distance shown in the table. A 2-inch by 2-inch (maximum) pressure treated

nailer may be placed at the finished floor elevation for attachment of interior finish materials.

Insulation extending away from the building shall be protected by pavement or by a minimum of

10 inches (254 mm) of soil.

R402.2.9 Slab-on-Grade Floors

Exterior applied foundation insulation on a monolithic slab

Prescriptive Checklist for the 2018 Washington State Energy Code - Residential 10

R402.2.8 Basement Walls

Exterior insulation R-10 continuous

Interior insulation R-15 continuous

Recommended wall assembly. R-13 batt applied over R-5 foam.

This is equivalent to an R-21 wall.

R-21 cavity allowed but not recommended

due to potential moisture problems

Do not install vapor retarders in below-grade walls

2012 International Residential Code

R702.7 Vapor retarders. Class I

or II vapor retarders are required

on the interior side of frame

walls in Climate Zones 5, 6, 7, 8

and Marine 4.

Exceptions:

1. Basement walls.

2. Below grade portion of any

wall.

3. Construction where

moisture or its freezing will

not damage the materials.

Prescriptive Checklist for the 2018 Washington State Energy Code - Residential 11

☐ R402.3.1 U-factor

An area-weighted average of fenestration products shall

be permitted to satisfy the U-factor requirements.

Example of Area Weighted U-Value Calculation:

Window #1 area 10 sf U = .34 U x A = 3.4

Window #2 area 15 sf U = .28 U x A = 4.2

Total area 25 sf Total U x A = 7.6

Area weighted average 7.6/25 = 0.30

The Glazing Schedule can help with this computation.

☐ R402.3.3 Glazed Fenestration Exemption

Up to 15 square feet (1.4 m

2

) of glazed fenestration per

dwelling unit shall be permitted to be exempt from U-

factor and SHGC requirements in Section R402.1.1. This

exemption shall not apply to the U-factor alternative

approach in Section R402.1.3 and the total UA alternative

in Section R402.1.4.

☐ R402.3.4 Opaque Door Exemption

One side-hinged opaque door assembly up to 24 square

feet (2.22 m

2

) in area is exempted from the U-factor

requirement in Section 402.1.1. This exemption shall not

apply to the U-factor alternative approach in Section

R402.1.3 and the total UA alternative in Section R402.1.4.

☐ Table 402.4.1.1 Air Barrier and Insulation Installation

Requirements

Air barriers and insulation must be installed in accordance

with Table 402.4.1.1, below.

☐ R402.4.1.2 Testing

The building or dwelling unit shall be tested and verified as having an air leakage rate of not

exceeding 5 air changes per hour.

Air Leakage Testing Specifications

Glazed Fenestration Exemption

Up to 15 sf of glazing are exempt from U-

factor requirements. This does not apply if

you are doing a UA tradeoff approach.

R402.3.4 Opaque Door Exemption

One door assembly, up to 24 sf, is exempt

from U-factor requirements

Prescriptive Checklist for the 2018 Washington State Energy Code - Residential 12

Prescriptive Checklist for the 2018 Washington State Energy Code - Residential 13

Prescriptive Checklist for the 2018 Washington State Energy Code - Residential 14

☐ R402.4.2 Fireplaces

New wood-burning fireplaces shall have tight-fitting flue dampers or doors and outdoor

combustion air.

☐ R402.4.2.1 Gas Fireplace Efficiency

All gas fireplace heaters rated to ANSI Z21.88 shall be listed and labeled with a fireplace efficiency

(FE) rating of 50% or greater in accordance with CSA P.4.1. Vented gas fireplaces (decorative

appliances) certified to ANSI Z21.50 shall be listed and labeled, including their FE ratings, in

accordance with CSA P.4.1.

☐ R402.4.4 Combustion Air Openings

Where open combustion air ducts provide combustion air to open combustion, space conditioning

fuel burning appliances, the appliances and combustion air openings shall be located outside of

the building thermal envelope, or enclosed in a room isolated from inside the thermal envelope.

Such rooms shall be sealed and insulated in accordance with the envelope requirements of Table

R402.1.1, where the walls, floors and ceilings shall meet the minimum of the below-grade wall R-

value requirement. The door into the room shall be fully gasketed and any water lines and ducts in

the room insulated in accordance with Section R403. The combustion air duct shall be insulated

where it passes through conditioned space to a minimum of R-8.

Exceptions:

1. Direct vent appliances with both intake and exhaust pipes installed continuous to the outside.

2. Fireplaces and stoves complying with Section R402.4.2 and Section R1006 of the International

Residential Code.

☐ R402.4.5 Recessed Lighting

Recessed luminaires installed in the building thermal

envelope shall be sealed to limit air leakage between

conditioned and unconditioned spaces. All recessed

luminaires shall be Type IC-rated and labeled certified

under ASTM E283 and shall have a label attached showing

compliance with this test method. All recessed luminaires

shall be sealed with a gasket or caulk between the housing

and the interior wall or ceiling covering.

☐ R403.1.1 Programmable Thermostats for Forced Air Furnaces

Where the primary heating system is a forced-air furnace, at least one thermostat per dwelling

unit shall be capable of controlling the heating and cooling system on a daily schedule to maintain

different temperature set points at different times of the day. The thermostat shall allow for, at a

minimum, a 5-2 programmable schedule (weekdays/weekends) and be capable of providing at

least two programmable setback periods per day.

R402.4.4 Recessed Lighting

Labeled and sealed recessed light

Prescriptive Checklist for the 2018 Washington State Energy Code - Residential 15

☐ R403.1.2 Heat Pump

Supplementary Heat

Unitary air cooled heat

pumps shall include controls

that minimize supplemental

heat usage during start-up,

set-up, and defrost

conditions. See R403.1.2 for

control and set-up

requirements.

☐ R403.3.1 Insulation

Ducts outside the building

thermal envelope shall be

insulated to a minimum of

R-8. Ducts within a concrete

slab or in the ground shall

be insulated to R-10 with insulation designed to be used below grade.

☐ R403.3.2 Sealing

Ducts, air handlers, and filter boxes shall be sealed. Joints and seams shall comply with either the

International Mechanical Code or International Residential Code, as applicable.

Exceptions:

1. Air-impermeable spray foam products shall be permitted to be applied without additional joint

seals.

2. For ducts having a static pressure classification of less than 2 inches of water column (500 Pa),

additional closure systems shall not be required for continuously welded joints and seams, and

locking-type joints and seams of other than the snap-lock and button-lock types.

☐ R403.3.3 Duct Testing

Ducts shall be leak tested in accordance with WSU RS-33, using the maximum duct leakage rates

specified.

RS-33 Duct Testing Standards

Exceptions:

1. The total leakage test or leakage to the outdoors is not required for ducts and air handlers

located entirely within the building thermal envelope. For forced air ducts, a maximum of 10

linear feet of return ducts and 5 linear feet of supply ducts may be located outside the

conditioned space. All metallic ducts located outside the conditioned space must have both

transverse and longitudinal joints sealed with mastic. If flex ducts are used, they cannot

R403.1.2 Heat Pump Supplementary Heat

Heat pumps with supplemental heat shall have lockout controls. Maximum

setting of 40° F, set to 35° F or less.

Prescriptive Checklist for the 2018 Washington State Energy Code - Residential 16

contain splices. Flex duct connections must be made with nylon straps and installed using a

plastic strapping tensioning tool. Ducts located in crawl spaces do not qualify for this

exception.

2. A duct air leakage test shall not be required for ducts serving heat or energy recovery

ventilators that are not integrated with ducts serving heating or cooling systems.

A written report of results shall be signed by the party conducting the test and provided to the

code official.

☐ R403.3.4 Duct Leakage

The total leakage of ducts, where measured in accordance with Section R403.3.3, shall be as follows:

1. Rough-in test: Total leakage shall be less than or equal to 4 cfm (113.3 L/min) per 100 square

feet (9.29 m

2

) of conditioned floor area when tested at a pressure differential of 0.1 inches

w.g. (25 Pa) across the system, including the manufacturer's air handler enclosure. All registers

shall be taped or otherwise sealed during the test. If the air handler is not installed at the time

of the test, total leakage shall be less than or equal to 3 cfm (85 L/min) per 100 square feet

(9.29 m

2

) of conditioned floor area.

2. Postconstruction test: Leakage to outdoors shall be less than or equal to4 cfm (113.3 L/min)

per 100 square feet (9.29 m

2

) of conditioned floor area or total leakage shall be less than or

equal to 4 cfm (113.3 L/min) per 100 square feet (9.29 m

2

) of conditioned floor area when

tested at a pressure differential of 0.1 inches w.g. (25 Pa) across the entire system, including

the manufacturer's air handler enclosure. All register boots shall be taped or otherwise sealed

during the test.

☐ R403.3.5 Building Cavities

Building framing cavities shall not be used as ducts or plenums. Installation of ducts in exterior

walls, floors or ceilings shall not displace required envelope insulation.

☐ R403.3.6 Ducts Buried within Ceiling Insulation

Where supply and return air ducts are partially or completely buried in ceiling insulation, such

ducts shall comply with all of the following:

1. The supply and return ducts shall have an insulation R-value not less than R-8.

2. At all points along each duct, the sum of the ceiling insulation R-value against and above the

top of the duct, and against and below the bottom of the duct, shall be not less than R-19,

excluding the R-value of the duct insulation.

Exception: Sections of the supply duct that are less than 3 feet (914 mm) from the supply

outlet shall not be required to comply with these requirements.

Prescriptive Checklist for the 2018 Washington State Energy Code - Residential 17

☐ R403.3.7 Ducts Located in Conditioned Space

For ducts to be considered as inside a conditioned space, such ducts shall comply with either of

the following:

1. All duct systems shall be located completely within the continuous air barrier and within the

building thermal envelope.

2. All heating, cooling and ventilation system components shall be installed inside the

conditioned space including, but not limited to, forced air ducts, hydronic piping, hydronic

floor heating loops, convectors and radiators. Combustion equipment shall be direct vent or

sealed combustion.

3. For forced air ducts, a maximum of 10 linear feet of return ducts and 5 linear feet of supply

ducts is permitted to be located outside the conditioned space, provided they are insulated to

a minimum of R-8.

3.1. Metallic ducts located outside the conditioned space must have both transverse and

longitudinal joints sealed with mastic.

3.2. If flex ducts are used, they cannot contain splices. Flex duct connections must be made

with nylon straps and installed using a plastic strapping tensioning tool.

☐ R403.5.3 Hot Water Pipe Insulation

Insulation for hot water pipe shall have a minimum thermal resistance of R-3. An SBCC

interpretation states that insulation can be discontinuous where passing through framing

members or where necessary to pass another pipe in a stud space.

☐ R403.5.5 Electric Water Heater Insulation

All electric water heaters in unheated spaces or on concrete floors shall be placed on an

incompressible, insulated surface with a minimum thermal resistance of R-10.

☐ R403.6.1 Mechanical Ventilation

A mechanical ventilation system is required to be installed in accordance with the

Washington State amendments to the 2019 International Residential Code. ASHRAE Standard 62.2

is an acceptable alternative for a single-family and townhouses, but is not an acceptable

equivalent for IMC low-rise multifamily.

☐ R404.1 Lighting Equipment

A minimum of 90% of permanently installed lamps in lighting fixtures shall be high-efficacy lamps.

Prescriptive Checklist for the 2018 Washington State Energy Code - Residential 18

Section R406 Additional Energy Efficiency Requirements

These tools are available to assist in determining energy and fuel neutrality credits (right-click the form

name and save it to your computer so you can use the form's automated functions):

Single-Family Prescriptive Worksheet

Multifamily Prescriptive Worksheet

Code Compliance Calculator

☐ R406.1 Scope

This section establishes additional energy efficiency requirements for all new construction covered

by this code, including additions subject to Section R502 and change of occupancy or use subject

to Section R505 unless specifically exempted in Section R406. Credit from both Sections R406.2

and R406.3 are required.

☐ R406.2 Carbon Emission Equalization

This section establishes a base equalization between fuels used to define the equivalent carbon

emissions of the options specified. The permit shall define the base fuel selection to be used and

the points specified in Table R406.2 shall be used to modify the requirements in Section R406.3.

The sum of credits from Tables R406.2 and R406.3 shall meet the requirements of Section R406.3.

☐ R406.3 Additional Energy Efficiency Requirements

Each dwelling unit in a residential building shall comply with sufficient options from Table R406.2

so as to achieve the following minimum number of credits:

1. Small Dwelling Unit: 3.0 credits

Dwelling units less than 1,500 sf in conditioned floor area with less than 300 sf of fenestration

area. Additions to existing building greater than 500 sf of heated floor area but less than 1,500 sf.

2. Medium Dwelling Unit: 6.0 credits

All dwelling units that are not included in #1, #3 or #4.

3. Large Dwelling Unit: 7.0 credits

Dwelling units exceeding 5,000 sf of conditioned floor area.

4. Dwelling units serving R-2 occupancies: 4.5 credits

5. Additions less than 500 square feet: 1.5 credits

The drawings included with the building permit application shall identify which options have been

selected and the point value of each option, regardless of whether separate mechanical, plumbing,

electrical, or other permits are utilized for the project.

Prescriptive Checklist for the 2018 Washington State Energy Code - Residential 19

Examples of how to obtain 6.0 credits for single-family residences:

Prescriptive Checklist for the 2018 Washington State Energy Code - Residential 20

Examples of how to obtain 6.0 credits for multifamily residences:

Prescriptive Checklist for the 2018 Washington State Energy Code - Residential 21