Lean Six Sigma White Belt

About Operational Strategic Initiatives

Mission

To continuously advance the

framework for UC San Diego’s

sustainable excellence by identifying

opportunities and providing solutions

that improve overall service,

dedication to people, and financial

stewardship.

Strategic Planning and

Initiatives

Tritonlytics

Innovation Management

Continuous Improvement

Projects and Workshops

Chancellor Support, Scholarships, OSI, Measurements

Projects

Projects Projects

Continuous

Improvement

Project

Management

Change

Management

Data

Analysis

Ideation Program, Trainings,

Communities of Practice

Top-

Down

Support

Bottom-

Up

Support

SPEED

ACCURACY RESULTS

What is Lean Six Sigma?

LSS Belt Levels

Black Belt

White Belts:

1. Basic LSS Terminology

2. How to identify Process

Issues

3. LSS Concepts

LSS Belt Levels

Black Belt

Yellow Belts:

1. Basic LSS Tools Application

2. How to identify root cause

3. How to select improvements

LSS Belt Levels

Black Belt

Green and Black

Belts:

1. Project-based application

2. How to measure

effectiveness of changes

3. How to leverage tools

effectively

Basic LSS Concepts

Everything we

do is a process

with a supplier

and customer

All processes

have variation

and waste – no

process is

perfect

All variation

and waste has a

cause

Known

causes can

be

eliminated,

reduced or

controlled

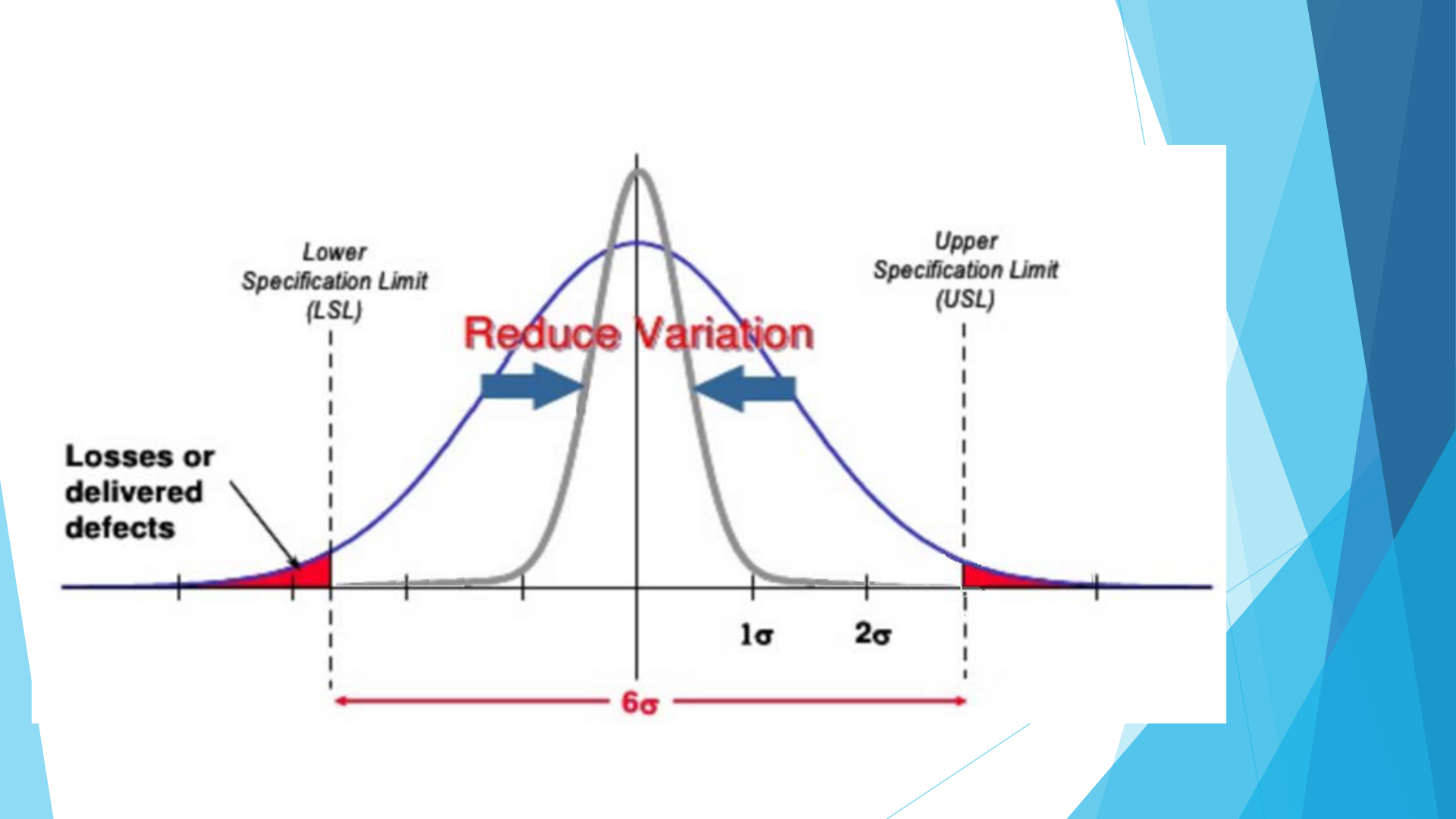

Pursuit of Perfection

To achieve Six Sigma, a process must fit within the customer specification

limits 99.9997% of the time

(i.e., only 3.4 out of 1 million instances are considered defects).

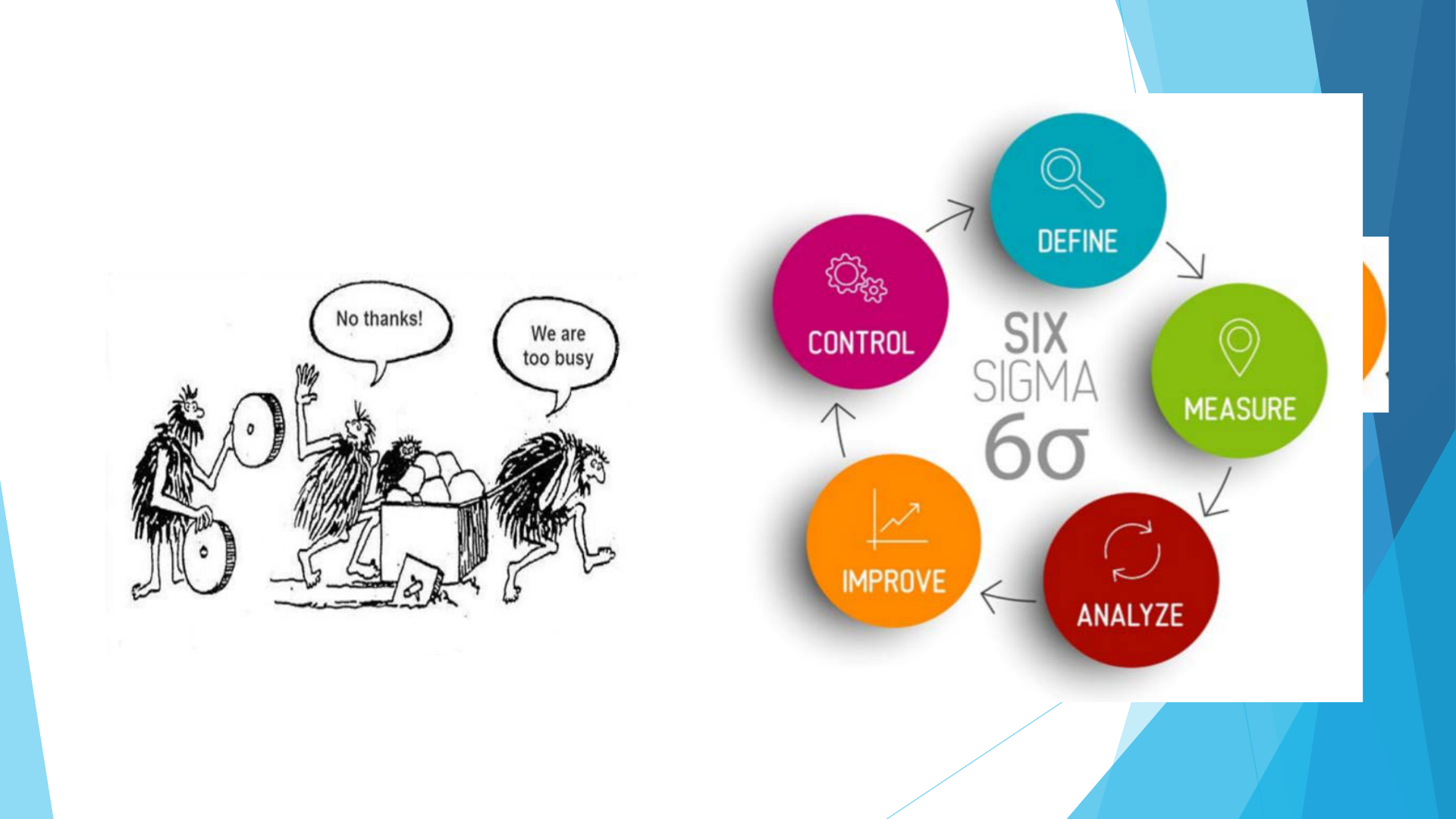

DMAIC Model

Problem Solving

Define: Project Charter

Business Case

Why is it important for the

business to complete this project?

What is the financial impact?

Scope

What’s in?

What’s out?

Team Members

Resources accessible to the team

Schedule

Define: Voice of the Customer (VOC)

VOC activities translate what customers say they

want into customer requirements: i.e., what customers find

“critical to quality” (CTQ) and what they define as a “defect.”

Defects can then be measured.

Continuous OR Discrete data?

Customer

Comment

Customer CTQ Customer

Definition

of Defect

Metric

What is being said? What is important to

customer?

What is not

acceptable for the

customer?

How will you measure

outcomes?

(time / pass-fail /

temperature / etc.)

Is there only one cook

back there or what!?

Food prep time Food takes too long to

prepare

45 seconds or less

Gemba Walk

• Gemba means “the real place” in Japanese

• Learn through observation and engagement: go to

the source(s) to experience a process firsthand

• Test your assumptions about a process against reality

• Go see, ask why, show respect

• Focus on the process, not evaluating the

people performing the process steps

Critical Path

Problem: How to make a complex process map into a linear Value

Stream Map?

Start

End

…the most common path

…the most costly path

…the longest path

Measure: Value Stream Mapping

■ Follow a product or service’s production path from beginning

to end.

■ Draw a visual representation of every process step in the

current material and information flows.

Start

End

Process

Process

Process

Process

Process

Process

Process

time

Wait time

Process

time

Wait time

Process

time

Wait time

Process

time

Wait time

Process

time

Wait time

Process

time

Analyze: Value Add Defined

Value Added to Customer: Process steps that matter to customers

Value Added to the Business: process work that does not create value from the

standpoint of the customer

Waste: Steps that create no value and can be eliminated

Value add requirements:

▪ The activity physically changes the product (or adds important information).

▪ The activity must be done right the first time (i.e., it should not be rework).

▪ Customers must be willing to pay for it.

Value

Added

Pure Waste

Business

Value

Added

8 Wastes: DOWNTIME

Analyze: Cause-and-Effect Diagram

A cause-and-effect diagram shows possible relationships between

potential causes in order to identify likely “root” causes.

• Can also be called a “Ishikawa” diagram or a “Fishbone” diagram

• Major causes and root causes make up the bones of the fish and are

grouped into categories

• Use the ‘5 Whys’ technique to get to the root cause

Problem

Mother

Nature

Process

People

Materials

Machine

Measurement

Rain

Power washing

Foot traffic

Climate Change

Cheap concrete

Earthquakes

Moving heavy

equipment

Age

Vandalism

Skateboards

Floors crumbling

Mother Nature

Process

People

Materials

Machine

Measurement

Analyze: 5 whys

Monument floors are crumbling – Why?

Harsh chemicals and power washing needed often – Why?

Lots of bird droppings – Why?

Many more tasty spiders around – Why?

Lots of yummy gnats around – Why?

Gnats are attracted to the lighting – Why?

Gnat biology – Why?

Frequency Plot / Histogram

■ A picture of the variation in a process

■ Reveals patterns that provide clues to certain types of

problems

■ Rough check if data are distributed normally

Run Charts and Examples of Signals

■ Trend:

6 or more points in a row

increasing or decreasing

■ Process Shift:

8 or more points in a row

above or below the mean

■ Bias or Sampling Problem:

14 or more points in a row

alternating up and down

(“saw tooth”)

Run Chart: Reveals trends over time and forms the basis for Control Charts that

check statistical significance of process variation.

Process Capability

To achieve Six Sigma, a process must fit within the customer specification limits 99.9997% of the time

(i.e., only 3.4 out of 1 million instances are considered defects).

Process Sigma Definition

■ Process Sigma (or σ) is a statistical concept that represents how

much variation there is in a process relative to customer specifications.

■ The Process Sigma value is based on defects per million opportunities.

■ “Six Sigma” is defined as 3.4 Defects Per Million Opportunities.

Lots of

variation

Hard to produce output with

customer requirements

(specifications)

Low sigma values

(0–2)

Moderate

variation

Very little

variation

Most output meets

customer requirements

Virtually all output

meets customer

requirements

Middle sigma values

(3–5)

High sigma values

(6)

Kaizen Format

Measure

Current

Process

•Objective analysis

of current state

•Value Stream Map

•Data Driven

Prioritize

Solutions

•Identify biggest

opportunities to make

improvements

•Identify root causes

Develop

Action

Plan

• Assign owners

and deadlines

• Progress

Updates

Control and Reaction Plan

What needs to be measured?

What safeguards should be built in

to avoid errors?

What standard operating

procedures need to be developed?

Who, how, and when will we assess

our new process?

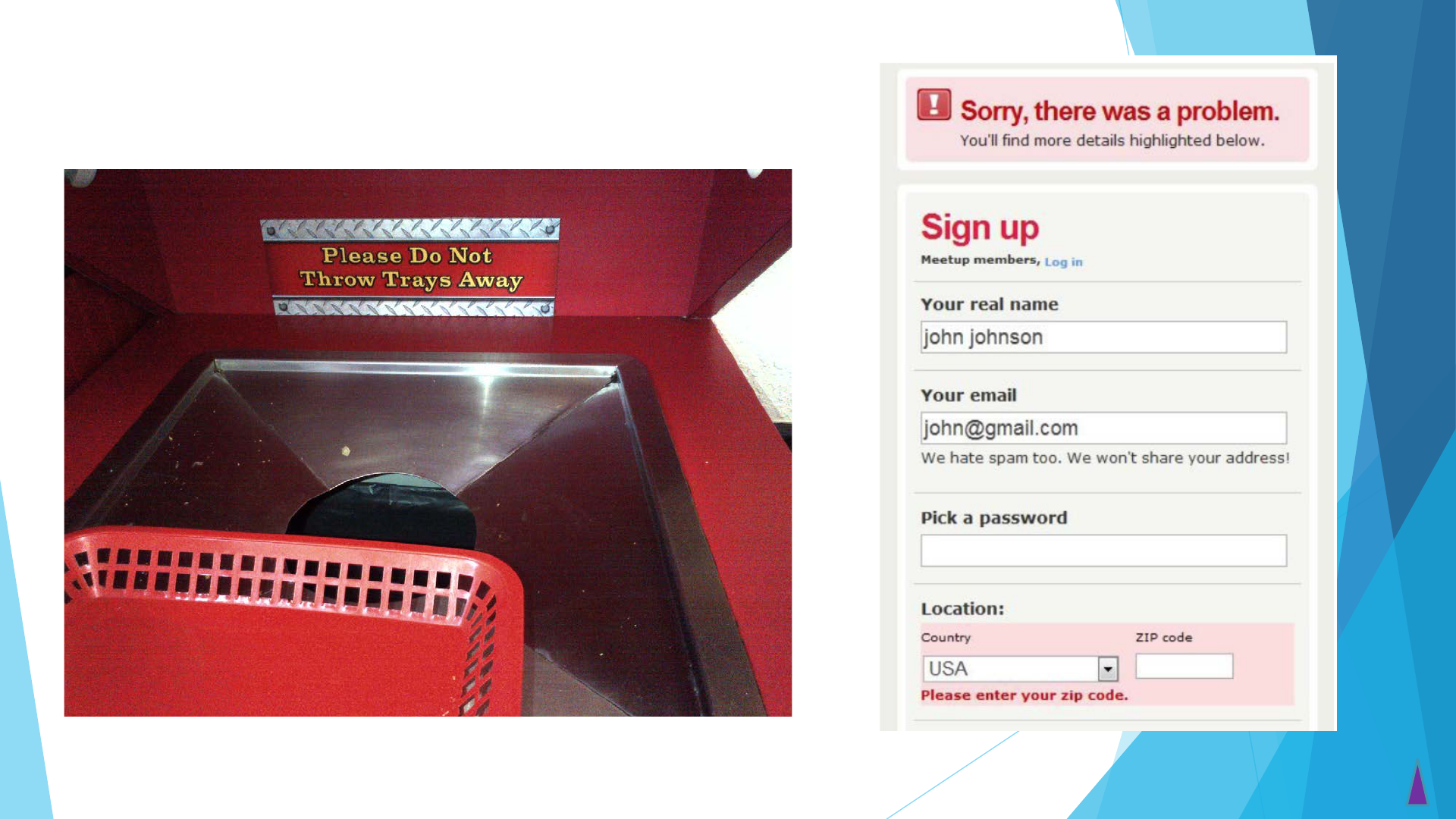

Controls: Mistake Proofing

Applications

Student employee travel requests returned fewer errors and reduced overall time by 7 days.

Travel Requests

Reduce resolution time for ITS systems downtime activity, resulting in more productivity,

less rework, greater compliance, and an annual savings of $250K ($285K to ~$3K).

Capacity

Reduce number of knife cuts in Housing Facilities by 50%

Safety

Create and implement process for tracking, measuring, and billing for oncology

drug waste in IV rooms. Results in approx. $1.6M annual revenue recovery

Inventory and waste

Improve UCSD Alumni Association Workzone tool to increase user satisfaction

survey score from 4 to 8.5 points

Quality

Reduce delivery time for ARUP lab paperwork to reach billing department

from 5-10 days to <5 days.

Billing

From the time a candidate is identified to the moment they received an official

offer letter, the cycle time was reduced from 5.5 months to 3.6 months.

Recruitment

Improve ITS onboarding process to eliminate unnecessary steps to increase

completion rate of onboarding form from 48% to 100%

Onboarding

Key Takeaways

LSS empowers employees at all levels to be change agents

Formal training provides a common language and tools

LSS emphasizes collaboration between departments, and can

address institutional silos

Change initiatives are more successful when true root cause is

addressed, and when all levels of staff are driving the change

Next Steps

What is your 15%?

Where do you have discretion and freedom to act?

What can you do without more resources or authority?

Thank you!

For more info regarding upcoming Lean Six Sigma

training and events, visit: osi.ucsd.edu

Or email us at: [email protected]u

Questions?