PROJECT PROFILE

NAME OF THE PRODUCT : PET Bottle

PODUCTION CAPACITY : Pet bottles (12, 00, 000 nos.)

Bottle Cap (60, 00, 000 nos.)

CAPITAL INVESTMENT : Rs. 25, 91, 300/-

MONTH & YEAR

OF PREPARATION : JUNE - 2020

PREPARED BY : MSME DEVELOPMNT INSTITUTE

GOVT. OF INDIA, MINISTRY OF MSME,

111 & 112 B.T.ROAD

KOLKATA - 700108

WEST BENGAL

2

1. INTRODUCTION OF THE PRODUCT:

The global plastics industry is observing a continuous shift of production

bases to low-cost Asian countries. With increasing foreign investment and rise in the

number of new manufacturing establishments in the region, Asia has become the

largest and the fastest growing market for plastics in the world. In particular, China

and India offer enormous growth opportunities due to expanding production

activities in the countries. Packaging sector is the largest application sector for the

plastic industry, representing almost 60.0% of the total plastics demand .plastic

consumption for packaging in India is expected to reach 12.0 million tons by 2025.

The FMCG sector compiled with the rise in capital investment pose as the key

growth drivers for the packaging industry in the country. The demand for packaging

of these products has to lead the development of the plastic packaging industry in

the country. Among the vast family of plastics, Polyethylene Terephthalate,

popularly known as PET, is expected to grow the fastest.

2. MARKET & DEMAND ASPECTS:

PET jar, PET bottles were the products of the firm. Polyethylene terephthalate

(sometimes written poly ethylene terephthalate), commonly abbreviated PET, PETE,

or the obsolete PETP, is the most common thermoplastic polymer resin of the

polyester family and is used in fibers for clothing, containers for liquids and foods,

thermoforming for manufacturing.

The global PET bottle market reached a volume of more than 19 Million Tons in

2019, registering a CAGR of more than 2.3% during 2011-2019. The market is

further projected to reach a volume of nearly 19 Million Tons by 2024, at a CAGR of

nearly 2.1% during 2019-2024. Polyethylene terephthalate (PET) refers to a

thermoplastic polymer resin of the polyester family which is widely used for

manufacturing plastic bottles. In comparison with PP, HDPE and PVC bottles, PET

bottles are more durable, transparent, lightweight, non-reactive, cost-effective and

thermally stable. Moreover, they are environment-friendly and can be recycled

repeatedly which further reduces their manufacturing cost. Primarily used in the

packaging of drinking water and beverages, PET bottles are also gaining

prominence as a packaging solution for salad dressings, household cleaners,

medicines, dish detergents and mouthwashes. The rising trend of westernization,

inflating disposable incomes and altering food patterns of consumers have

3

increased the demand for bottled beverages, particularly in developing countries like

India and China.

PET bottles are bottles made-up of a plastic resin chemically known as polyethylene

terephthalate and abbreviated as PET. Due to some inherent properties of PET

resin, these bottles are transparent, light-weight, high in strength and impermeable

to carbon dioxide. Their manufacturing is based on a stretch blow-moulding process,

which provides strength and high resistance to bear internal pressure and enables

them to be stacked like glass bottles.

Primarily used in the packaging of water and beverages, PET bottles are also

gaining shares in other industries like- juices, salad dressings, household cleaners,

medicines, dish detergents, mouthwashes, etc. Being light in weight and easy to

handle, they are preferred in the packaging of carbonated soft drinks (CSD's) and

are continuously replacing glass bottles due to their tendency to break and the

inconvenience created while returning them after consumption.

3. BASIS AND PRESUMPTION:

a) The scheme is based on single shift of 8 hours per day and 300 working days

per annum.

b) The interest rate on the borrowed capital has been taken as 12 % per annum.

c) The cost in respect of Raw Materials, Packing Materials, Machinery &

Equipments has been taken at the time of preparation of project profile and

may vary from place to place and time to time.

d) The rental Value of production shed is taken as per the prevailing rates and

may vary from place to place.

e) The plant capacity utilization has been taken as 50 % for the first year, which

masy subsequently increase to 60% and 70% in the second and third year

respectively.

4

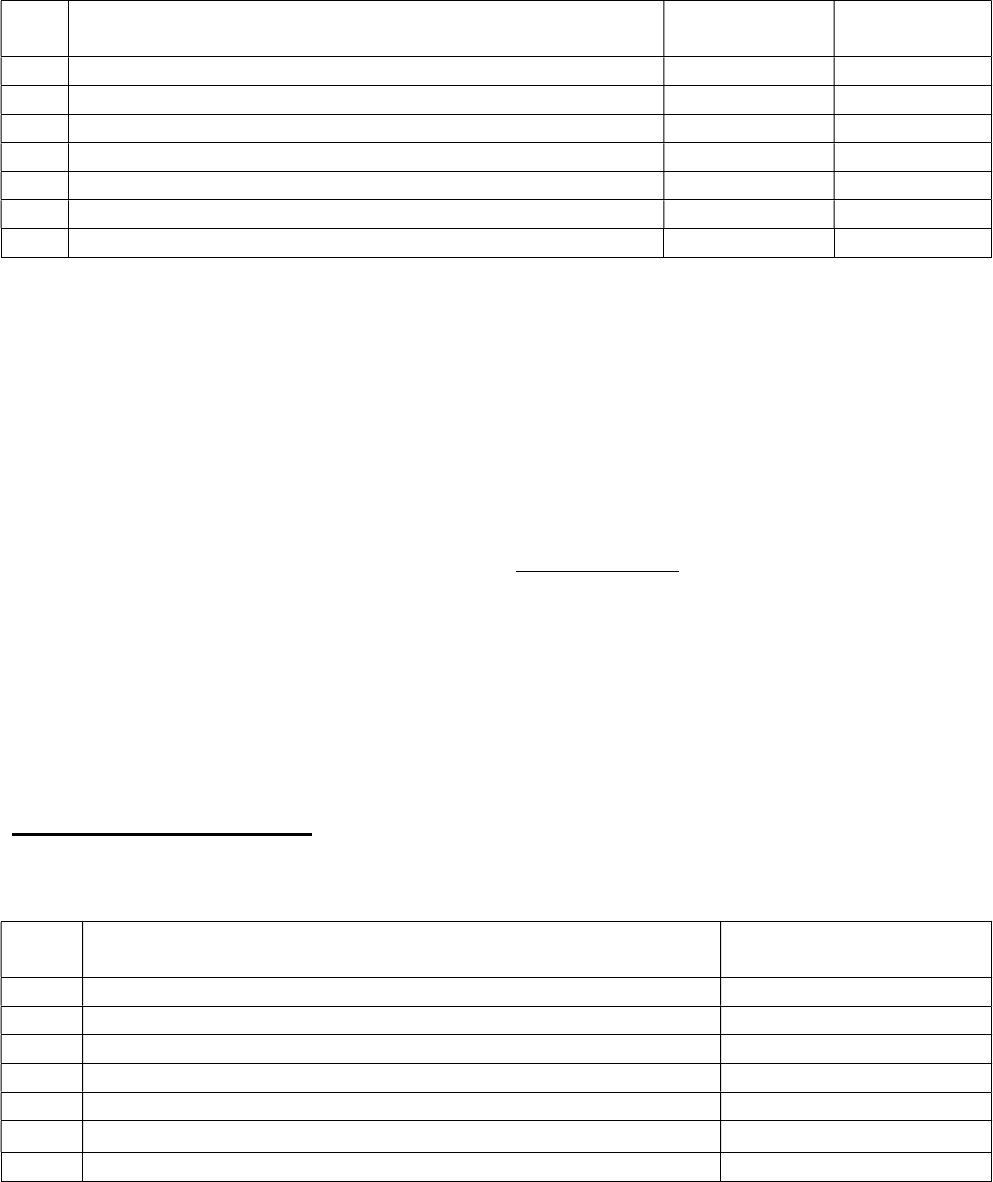

4. IMPLEMENTATION SCHEDULE:

Preparation of The project implementation will take about nine months. The

break-up of activities with relative time for each activity is as follows:

Sl.

No.

Activity

Estimated time

periods (Months)

01. Scheme preparation & approval 0 – 1

02. Registration under MSME Act 2006 and sanction of loan 1 - 3

03. License from FDA 2 – 3

04. Placement of Orders for Machines 2 – 3

05. Power Connection 1 - 2

06. Installation of Machines 3 - 4

07. Recruitment of Staff & Trial run 4 - 5

08. Commercial Production 5

th

onwards

5. POLUTION CONTROL NEEDS:

There is no such harmful effluent coming out of this factory. But dumping of

wastage may create problem. Proper attention should be given to dump the scrap.

The unit should obtain No Objection Certificate from the State Pollution Control

Board. Workers must be provided hand gloves and masks during operation.

.

6. TECHNICAL ASPECTS:

Polyethylene Terephthalate is a thermoplastic polymer that can be either opaque or

transparent, depending on the exact material composition. As with most plastics,

PET is produced from petroleum hydrocarbons, through a reaction between

ethylene glycol and terephthalic acid. To produce plastic bottles, the PET is first

polymerized to create long molecular chains.

Polymerization itself can be a complicated process and accounts for many of the

inconsistencies between one batch of manufactured PET and another. Typically,

two kinds of impurities are produced during polymerization: diethylene glycol and

acetaldehyde. Although diethylene glycol is generally not produced in high-enough

amounts to affect PET, acetaldehyde can not only be produced during

polymerization but also during the bottle manufacturing process. A large amount of

acetaldehyde in PET used for bottle manufacturing can give the beverage inside an

odd taste.

Once the plastic itself has been manufactured, the bottle manufacturing process can

begin. To ensure that the PET is appropriate for use, numerous tests are done post-

manufacturing to check that the bottles are impermeable by carbon dioxide (which is

5

important for bottles that carry soda). Other factors, such as transparency, gloss,

shatter resistance, thickness, and pressure resistance, are also carefully monitored.

The first stage of a typical 2-step Reheat and Blow Machine (RBM) bottle

manufacturing process is injection moulding. Plastic pellets are plasticized in the

barrel of an injection moulding machine where the plastic is melted by heat and the

shearing action of a feed screw. The plastic is then injected into multiple-cavity

moulds where it assumes the shape of long, thin tubes. These tubes, called

parisons, usually include the formed necks and threads that will be used to cap the

bottles that are yet to come. PET parisons, or pre-forms, are easily shipped to

bottling facilities as they are much more compact than fully formed bottles.

During the re-heat process, the parisons are loaded into a feeder and run through

an unscrambler, which orients the parisons for feeding into the blow moulding

machine. The parisons are heated by passing by quartz heaters and then enter the

mould. Here, a thin steel rod, called a mandrel, slides into the neck of the parison

where it fills the parison with highly pressurized air, and stretch blow

moulding begins: as a result of the pressurized air, heat, and pressure, the parison

is blown and stretched into the mould axially and radially, where it assumes a bottle

shape. This process produces what is called a bi-axially oriented bottle which

provides a CO

2

barrier ideal for containing carbonated beverages.

The mould must be cooled relatively quickly, so that that the newly formed

component is set properly. There are several cooling methods, both direct and

indirect, that can effectively cool the mould and the plastic. Water can be coursed

through pipes surrounding the mould, which indirectly cools the mould and plastic.

Direct methods include using pressurized air or carbon dioxide directly on the mould

and plastic.

Once the bottle (or, in continuous manufacturing, bottles) has cooled and set, it is

ready to be removed from the mould. If a continuous moulding process has been

used, the bottles will need to be separated by trimming the plastic in between them.

If a non-continuous process has been used, sometimes excess plastic can seep

through the mould during manufacturing and will require trimming. After removing

the bottle from the mould and removing excess plastic, the plastic bottles are ready

for transportation or filling.

Other bottle manufacturing processes combine the formation of the parisons and the

blow moulding in a single continuous process. One such machine is a continuous

extrusion machine wherein an extruder is continuously producing a parison. In

the extrusion blow moulding process, the parison forms vertically and its wall

thickness is varied by changing the size of the orifice through which the parison

extrudes. Mould halves close over the suspended parison and transfer it to the blow

moulding station where the bottle is formed as in the second step of the RBM

process described above. Varying the wall thickness solves the problem of non-

6

uniformity of the hanging parison as the weight of the formed portion would

otherwise stretch the hot and still-forming section above it. Wall thickness is thus

increased as the parison forms to create a uniform thickness throughout the

formation.

Another manufacturing process is the reciprocating blow moulding machine. These

machines move the screw linearly within the injector barrel to accumulate a shot.

Then the screw pushes the shot over the mandrel to create the parison after which it

is formed in the usual manner.

Raw Materials:

PET is a plastic resin derived from petroleum hydrocarbons. The producer creates

long chains of plastic molecules through a process called polymerization, and then

mixes the material with several chemical compounds. They cut the resin into small

pellets and send it on to the bottle manufacturer. The bottle plant mixes PET resin

pellets with "regrind" -- recycled plastic that has been reduced to flakes. Plastic

loses some of its physical properties when repeatedly heated, so manufacturers

must limit the amount of regrind they use, typically capping this ingredient at 10%

of the total mix. Unless producing clear bottles, dyes are introduced to the mix as

well.

Building a Preform:

An extruder melts the PET and regrind mix at temperatures of about 500 degrees

Fahrenheit. A screw inside the extruder compresses the PET mix and injects the

nearly molten material into molds. The mold produces a bottle preform, which is

sometimes called a parison. The preform looks like a thick-walled test tube, often

including the bottle’s characteristic screw top. The preform cools as it travels to a

machine called a blow molder, and may need to be brought back up to the

manufacturer’s specified temperature for that operation. If necessary, the bottle

manufacturer raises the temperature of the preform in a small oven.

Stretching the Preform:

The preforms enter a two-part mold that closes around it. The inside of this mold is

shaped exactly like the finished bottle. Inside, a long needle pushes up through the

preform, which is suspended with the screw end facing downward. The needle

stretches the preform upward toward the top of the mold -- which will be the

bottom of the bottle -- and simultaneously blasts enough pressurized air into the

preform to force it against the sides of the mold. This stretch blow molding process

must happen quickly in order to maintain the bottle’s integrity and consistent

shape. Some manufacturers weld a separate bottom piece to the bottle during

blow molding, while others produce a bottom from the preform along with the rest

of the bottle.

7

Cooling and Trimming:

The bottle must be cooled almost instantly or it will lose its shape when gravity

causes it to creep downward in its malleable, heated state. Some manufacturers

cool the bottle by circulating cold water or liquid nitrogen through the mold, others

elect to fill it with a shot of air at room temperature. The mold typically yields a

clean bottle, but some flashing may occur at the bottle seams, where the two mold

halves met. If so, operators trim away the excess material and add it to the regrind.

7. FINANCIAL ASPECTS:

Land: 10, Gunth . Own.

Shed: 1500 sft.@Rs. 300/- per Sq. ft Rs. 4, 50, 000/-

Boundary work and others expenses L.S. Rs. 1, 88, 000/-

Rs. 6, 38, 000/-

i) Machinery & Equipments:

Sl.

No.

Specification. No. Rate Value

1. Blow moulding machine to make Pet

bottles from preform pet of cap.250

ml to 2.5 lit. (2 KW)

1 8, 00, 000 8, 00, 000

2. Injection moulding machine to make

diff. Plastic Cap with 3 KW motor)

1 3, 00, 000 3, 00, 000

3. Scrap grinder (5 HP motor) 1 50, 000 50, 000

4. Office furniture LS 58, 000

5. Installation charges @ 10% 1, 15, 000

Total

13, 23, 000

PRE-OPERATIVE EXPDITURE:

Project profile 1500

Travel and transport 10000

Stationery 5000

Telephone 2000

Sale Tax Registration (GST) 5000

Other misc. expr. 12000

Rs. 35, 500/-

Fixed capital Investment = Rs. 6, 38,000/- + Rs. 13, 23, 000/- + Rs. 35, 500/-

= Rs. 19, 96, 500/-

8

WORKING CAPITAL ANALYSIS:

i) Staff and labour payment (Per month):

Sl.

No.

Designation No. Salary

Total

Amount

(In Rs.)

01. Manager Self

02. Supervisor 2 10000 20, 000

03. Skilled Labour 4 8000 32, 000

04. Unskilled Labour 10 6000 60, 000

05. Mechanic 1 8000 8, 000

05.

Clerk cum Accountant

1 8000 8, 000

06. Watchman cum Peon 1 6000 6, 000

Total

1, 3

4, 000

ii) Raw materials to prepare 500 lit. of alcoholic hand sanitizer:

S

l.

no

Materials Qty. Rate Value in Rs.

1.

Preform pet bottle 1,00,000 @ 2.00/pc 2,00,000

2.

HDPE 2500 kg @ 80/kg 2,00,000

3.

Lubricants filler etc

L.S 25, 000

Total

4, 25, 000

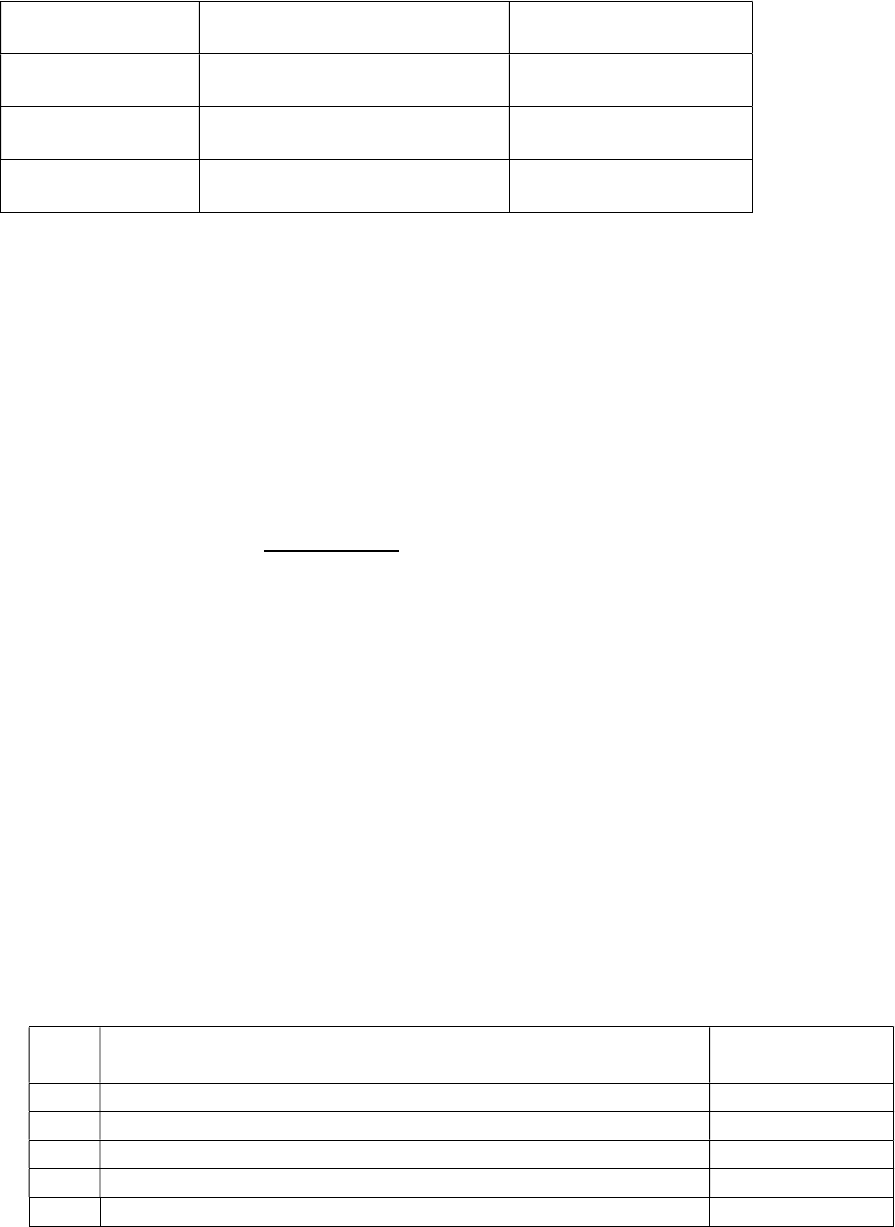

ii) Utility:

S

l

.

No.

Description Rate Quantity Value (Rs.)

01. Power Rs. 6/ unit 1000 KWH 6, 000

02. Water L.S 2, 000

Total

8, 0

00

9

iii) Other Expenses (Per Month):

Sl.

No.

Description Quantity Value

01. Postage & Stationery L.S 10, 000

02. Telephone L.S 1, 500

03. Repair & Maintenance L.S 1, 500

04. Insurance @ 2% of Machinery & Equipment Cost L.S 2, 500

05. Marketing & Travelling Expenses L.S 200

06. Other Misc. Expenses L.S 12, 000

Total

2

7

, 700

WORKING CAPITAL (PER MONTH):

= Rs. 1, 34, 000 + Rs. 4, 25, 000 + Rs. 8, 000 + Rs. 27, 700 = Rs. 5, 94, 700/-

TOTAL CAPITAL INVESTMENT:

Fixed capital Rs. 19, 96, 500

Working capital (1 month) Rs. 5, 94, 700

Total = Rs. 25, 91, 200/-

Means of finance:

Promoter contribution @ 25% Rs. 6, 47, 800/-

Bank finance @ 75% Rs. 19, 43, 400/-

FINANCIAL ANALYSIS

(a) COST OF PRODUCTION (PER ANNUM):

Sl.

No.

Description Value (Rs.)

01. Raw Material & Packaging Material 51, 00, 000

02. Salary & Wages 16, 08, 000

03. Utilities 96, 200

04. Other Expenses 3, 32, 400

05. Depreciation on Machinery & Equipments @ 10% p.a. 1, 20, 800

06.

Interest on borrowed capital @ 12 % p.a.

2, 33, 208

Total

74

,

90

,

6

08

10

(b) TURNOVER (PER ANNUM):

Item Quantity & Rate Value in Rs.

Pet bottles 16,00,000 @ 3.00/ bottle 48, 00, 000

Caps 60 lakhs @ 0.60/pc. 36, 00, 000

84, 00, 000

(C) NET PROFIT PER YEAR:

Net Profit = Total turnover - Total cost of production

= 84, 00, 000 - 74, 90, 608

= 9, 09, 392

(D) Profit Ration on Sales :

Profit ratio on Sale: = Profit x 100 = 10.82 %

Turnover

(e) Rate of Return (ROR) on Total Capital Investment:

Net Profit per annum

ROR = ---------------------------- x 100

Total Capital Investment

9, 09, 392

= ---------------------- x 100

25, 91, 200

= 35.09 %

(f) Break Even Analysis:

(i) Fixed Cost

Sr.

No.

Description Amount (Rs.)

01. Depreciation on Machinery & Equipments @ 10% p.a.

1, 20, 800

02. Interest on Total Capital Investment @ 12 % p.a.

2, 33, 208

03. 40 % of Salary & Wages

6, 43, 200

04. 40 % of Other Expenses

1, 32, 960

Total

11, 30, 1

68

11

(ii) Break Even Point (BEP):

Fixed cost x 100 = 55.41%

B.E.P. = Fixed cost + Profit

ADDRESSES OF MACHINERY AND EQUIPMENT:

Address of Raw material suppliers:

1. M/s. Sun Temple International ,C/o-P.K.Badapanda ,Khan Nagar Nua sahi, Link Road Santosh

Petrol Pump Lane ,Cuttack-753012 ,9437356700 ,9861810015 ,Tel-0671-2367123

{Dealls in ( all type of Acid ,Chemicals ,Solvent ,perfume,Essence ,Colour )

Specialise : Raw material & chemicals for MAKING:-ATAR .AGARBATI,LIQUID BLUE (Ujala type) ,LIQUID ACID (Harpic

type) ,HAND WASH , SANITIZER, SOAP,DETERGENT ,ROOM FRESHNER ,PHYNYLE

Cosmetic Chemical, CHALK/CANDLE MOULD .all type of SPRAYERS

Raw Material Suppliers:

1) M/s. Sony Purfumary Works, C/o. Sri P.K. Nayak, Near Santha Nirankari Sathsangha

Bhawan, Rajendra Nagar, Madhupatna, Cuttack. Tel-641442

2) M/s. Mother India Chemicals, Near Durga Mandap, Khapuria.

Tel-644491

3) M/s. R.K. Trading , Bakharabad, Cuttack-2, Tel-622021

4) United Chemical Company, Agarpara, Kolkata-700058

5) Akshar Exim Company Pvt. Limited, Dakhin Mart, Kaikhali, Kolkata

6) Naveen Enterprise, South DumDum. Kolkata

Pet bottles/tin containers:

1. M/s.Sai chem Industries, Madhupatna, Cuttack-751010.

2. M/s.Chauhan Brothers, Jayshree Cinema Backside, Badambadi, Cuttack. Tel. 318644.

3. Essence & Bottle Supply (India) Pvt.Ltd., P.O.Box : 372, 14, Radha bazar Street, Calcutta-

700001. Tel.2254994.

4. KKR Industries, Bura Bazar Market, Kolkata

5. Chirag Group of company, Dhakuria, Kolkata