1

lyondellbasell.com

Handling and Storage of

LyondellBasell Polymers

Table of Contents

Introduction

3

Handling and Storage of LyondellBasell Polymers 4

Operation Clean Sweep 4

How LyondellBasell Products Get to Customers 5

Transfer and Storage Systems 5

Piping Design 7

Layout and Length 7

Pipe Interior 8

Transfer System Air 9

A Pressurized-Air, Dilute-Phase System 9

A Vacuum, Dilute-Phase System 10

The Silo 11

Funnel or Mass Flow Design 11

Measuring the Resin in the Silo 12

Handling a Delivery of Pellets or Powder 13

Recommended Safety Points Before Opening Hatches 13

Static Electricity 13

Preparing the Hopper Car for Unloading 14

Unloading the Hopper Car 14

Hoses 14

Venting 16

Plant Transfer System 16

After Unloading Each Compartment 16

After the Car is Completely Unloaded 17

Unloading Checklist 18

Differences Between Hopper Truck and Hopper Car Unloading 19

Gaylord Box Handling 19

50-lb. Bag Handling 20

Special Handling for LyondellBasell Performance Polymers 20

Ethylene Copolymers 20

Wire and Cable Resins and Compounds 20

Polyolefin Powders 21

Quality Assurance 21

Meeting the Goals of Operation Clean Sweep 22

Appendix 1: Pellet Conveying Troubleshooting Guide 24

Appendix 2: Safety and Handling Information for Microthene F Microfine

Polyolefin Powders 27

Appendix 3: Trade Names for Products of LyondellBasell Chemicals, LP 28

3

INTRODUCTION

The movement of polymer pellets is a necessary part of our production, shipment and the

customers’ handling of these products before processing. At our customers’ facilitiy a

smooth transfer of resin from delivery vehicle to silo starts with the design of the transfer

system itself and ends with proper procedures for daily operations. To assist customers

with the safe and proper handling and storage of our polyolefin products, this manual

provides recommendations for:

Piping design

Transfer system air

The silo

Safety points

Unloading hopper cars, hopper trucks and handling Gaylord boxes and 50-pound

bags

Special handling required for performance products

A troubleshooting guide

Following these suggested policies and procedures can minimize the contamination

associated with pellet movement that might cause difficulties in production.

When pellets are transferred at high velocities through a piping system, the heat

generated from the friction between the pellets and the pipe surface causes the pellets to

warm to their softening point. At this temperature, part of the pellet softens and smears

on the interior walls of the piping where it almost instantly solidifies again, forming a skin

along the pipe surface. Further transfers of polymer cause this skin to peel off, resulting

in strands of polymer of varying lengths mixed with the pellets. These strands, commonly

referred to as “streamers,” “angel hair” or “snakeskin,” can plug the filters of the

conveying system. As different grades of material pass through the system, the

streamers may have different physical properties. These streamers, if they make their

way to the processing operation, can contaminate the feed material and stop production.

“Fines” are created from the abrasion that occurs as the pellets come in contact with the

surfaces of the piping system. When the pellets bounce against the surface of the pipe,

very small pieces can break off the surface of the pellets. These tiny pieces of polymer

act like dust and can plug the filters in a vacuum-driven piping system. In sufficient

quantity, fines can also interrupt production.

4

HANDLING AND STORAGE OF LYONDELLBASELL POLYMERS

LyondellBasell

(because

LyondellBasell in this

powders

for

and specialty

sealants and coatings.

LyondellBasell

and/or

(Figure 1).

Operation Clean Sweep

LyonndellBasell

a

.

The U.S. EPA’s Storm Water Regulations classify resin pellets as “significant

materials,” making the exposure of even a single pellet in storm water run-off

without a permit subject to regulatory action.

On pages 2 3-24 of this manual

is a list of specific steps to prevent resin release into the environment.

Figure 1.

5

LyondellBasell

(Figure 2).

LyondellBasell

also

Figure 3.

LyondellBasell

Figure 4

Figure 2.

Figure 3.

and

TRANSFER AND STORAGE SYSTEMS

HOW LYONDELLBASELL PRODUCTS GET TO CUSTOMERS

6

This system’s major disadvantage is its limited conveying range. The greater the

distance the pellets must travel, the greater the vacuum pulled must be. With higher

vacuums, the air-to-solids ratio is increased and leads to slower unloading.

Hopper trucks use a built-in system of blowers that push the resin out and into the

in-plant transfer system. Optimum hopper truck pick-up air velocity is 4,500 feet per

minute (fpm).

The most common in-plant transfer system is a dilute-phase system. Dilute-phase

systems are sometimes called “stream-flow conveying.” A high-enough air velocity

and a low-enough conveyed solids-to-air ratio characterize this system so the solids

pass through the line suspended in a relatively uniform stream.

If the piping (also called “lines”) in the in-plant transfer system is not designed

properly, problems can result, including inefficient resin transfer, generation of fines

and streamers, contamination, excess power usage and increased downtime as

lines must be disassembled more often for thorough cleaning. The following

sections of this manual review several parts of the transfer system.

Figure 4. Recommended resin pellet handling/storing system for unloading a railcar or truck.

7

PIPING DESIGN

Layout and Length

The layout and length of the transfer piping or lines determine to a large extent how

easy and trouble-free it is to move the resin from the car or truck to the silo. Transfer

piping should run as short a distance as possible between the unloading area and the

storage silo. Shorter distances mean fewer opportunities for contamination to enter the

system or for fines and streamers to form within the system. Parking and unloading

areas for hopper trucks should optimally be around 20 feet from the silo; 40 feet is the

maximum distance for efficient unloading. However, since hopper cars go only where

the rails take them, transfer piping between rail sidings and silos can be considerably

longer.

In designing a transfer system, the engineer must strike a balance between minimizing

the distance from the unloading sites to the storage silos and minimizing the distance

from storage silos to work areas. Transfer piping between the silo and the processing

machines should optimally run no more than 200 feet to 300 feet. Keeping to that mea-

sure may mean much longer lengths of transfer piping on the front end from the unload-

ing area to the storage silo.

One mistake often made in the design of a

transfer system is not allowing enough

time for the pellets to reach velocities that

prevent saltation. At the saltation point, the

air velocity is no longer high enough to

keep the pellets moving. The pellets fall

out of the air stream and move along the

bottom of the piping. This movement

increases power requirements and can

lead to plugging of the system. To provide

the time needed for the pellets to enter the

conveying air stream at the bottom of the

silo and reach conveying velocities, a

straight section of piping, equal in length to

20 times the diameter of the pipe used, is

necessary before reaching a vertical bend

or “elbow.”

Transfer piping should run horizontally and

vertically, not diagonally. In other words, all

elbows — and the number of elbows should

be kept to a minimum — should have angles

of 90 degrees. Tipping the piping should be

avoided. If the pipes must be tipped, then their

slant should be no more than 10 degrees from

the vertical or horizontal plane. Sloped or tipped

lines allow the pellets to slide back and can

lead to plugging of the line (Figure 5).

Figure 5. Piping sections running horizontally

and vertically with elbow, showing

correct and incorrect angles.

8

Long radius elbows are not recommended for pellet conveying when streamers are

a concern. “Blinded tees,” or other specialty elbows designed to minimize creation of

fines and streamers, should be used (see Figures 6-9). Contact your LyondellBasell

technical service representative for further details.

If possible, long horizontal distances should be avoided.

It is easier to push pellets vertically than horizontally.

Because of their bulk density, pellets are more likely to fall out of the air stream

as they move horizontally.

Less blowing air is needed to move the resin vertically.

The horizontal movement of the pellets along the pipe walls builds up heat in the

pipes, which can lead to the formation of fines and streamers.

In short, in laying out transfer system piping, minimize the number of changes in direction

the flow of pellets must take from their unloading point to the storage silo. Minimizing

the number of bends, twists and turns in the

transfer piping minimizes the occurrence of

pressure drops as the pellet stream moves

through the piping.

Fewer pressure drops mean fewer chances

for pellets — softened by their exposure to

friction and warm blowing air – to drop out

of the stream, slide along the walls of the

elbows and create streamers. More on

these types of contamination follows in the

next section of this manual.

Pipe Interior

Decreasing the time the pellet slides along

the pipe’s interior surface reduces the sliding

friction that can cause streamer formation.

The most common way to minimize this time

is to roughen the inside surface of the

conveying line. When pellets contact a rough

surface, they roll or tumble instead of slide.

When the pellets bounce against the rough

surface, they do leave a very small amount

of residue called fines. After bouncing

against the rough surface, the pellets

continue in the direction of the airflow.

Conveying pipes can also be purchased with

specially manufactured, rough, interior

surfaces. LyondellBasell plants use various types

Figure 6. A blinded tee

Figure 7. Blinded tees

9

LyondellBasell

technical

Figure 9. Blinded tees

Figure 8. Blinded tees

Appendix 1

TRANSFER SYSTEM AIR

same system.

information.

10

A Pressurized-Air, Dilute-Phase System

The air transfer system that moves pellets from the hopper car must be constantly

monitored. Some form of cooling system using water or air is necessary. The

temperature of the transfer air should not exceed 100°F when conveying PE

homopolymers and all PP products. Higher temperatures can add to the effect of

friction and soften the pellets, leading to streamer formation, as described previously.

If the pellets are ethylene copolymers, the air temperature must be maintained at

even lower temperatures. Blowers on ethylene copolymer transfer lines should be

cooled with chilled water to an air temperature of about 90°F. See Table 1 for the

softening point – not the melting point – of the resin that you are purchasing. The

transfer-air temperature must be kept well below that level.

1

Softening point temperature has a range of ± 15 °F

Table 1

Transfer air should be filtered to prevent contamination of the resin by debris. Hopper

trucks are equipped with filters on the inlet and outlet sides of their blowers, but filters must

be attached to hopper car hatches (on non-vented cars) and outlet tubes. If filters are

clogged or dirty, the temperature of the transfer air rises. REGULAR MAINTENANCE IS

ESSENTIAL.

Typically, about 2.5 cubic-feet-per-minute of air are used for each pound of material being

conveyed. The minimum pick-up velocity for a pressure system is 4,200 fpm. A higher pick-

up velocity increases the friction of the pellets on the pipe, increasing the chance of

streamer formation. A lower pick-up velocity may go below the “saltation point,” the velocity

at which pellets begin to settle out of the air stream to the bottom of the piping. Optimum

pick-up velocity is approximately 4,500 fpm.

Air temperatures must be kept as low as possible. For every pound the air pressure

increases across a blower and filter, the air temperature increases about 15°F. The ideal

air temperature of 90°F after the blower should be maintained with an air cooler.

The pressurized air system is designed so the air stream is separated from the pellets by a

filter. The pellets are released from the air stream, but fines and streamers, if present,

accumulate on the filter. After transfer the filter is pulsed with a blast of high-pressure air to

dislodge the fines and streamers, which are then collected for disposal. Without regular

maintenance, the weight of the accumulated fines and streamers can cause the built-up

material to drop into the flow of pellets and clog the transfer system.

11

A Vacuum, Dilute-Phase System

Particularly for temperature-sensitive resins, such as ethylene copolymers and

crosslinkable wire and cable compounds, vacuum conveying works better than

pressurized air systems. Although more expensive to install and operate, conveying

temperatures in a vacuum system are lower, which prevents problems discussed

earlier. The most common transfer systems for hopper-car unloading utilize vacuum

conveying.

For vacuum conveying in a dilute-phase system, the pellets go into a disengagement

hopper which separates the air from the material being transferred, thus avoiding the

accumulation of fines and streamers that can plug the transfer system.

THE SILO

Funnel or Mass Flow Design

For a silo to accommodate a hopper carload of polyolefin resin, it must be able to hold

200,000 pounds. Ideally, silos are made from stainless steel, but aluminum and carbon

steel silos with epoxy linings are common. This lining must be checked periodically for

wear. If the lining is worn and thin in areas, contamination of the resin can result where

the pellets contact the carbon steel (Figure 10).

Figure 10. Silo with a 60-degree

cone-shaped bottom for

ease of product flow

and maintenance.

Silos are usually designed to store products within a range of bulk densities. If you do

not know whether your silo was designed to handle polyolefins, contact the

manufacturer. Silos can collapse if the bulk density of the stored material is too high

for the silo to handle. CAUTION: Do not overload your silo. For the typical bulk

density of LyondellBasell polymers, see Table 2.

12

Silos with diameters of 10 feet are common, but silos with 12- and 14-foot diameters

are now available. The standard cone-shaped bottom of the silo has an angle of at

least 60 degrees for the polymer to flow easily; silos with larger diameters must be

supported at a greater height above the ground than silos with smaller diameters.

However, larger diameter silos are shorter in height overall than ones with smaller

diameters, an advantage in terms of handling product. Cone bottoms with slopes of 60

degrees or more are recommended. These bottoms are easier to clean and maintain

and are necessary if the silo is used to store polyolefin powders.

At the bottom of the silo cone is a rotary airlock, a device that prevents air loss when

the resin is transferred or removed from storage and controls the feed rate to the

conveying system. The controls on this device should be connected to the blower so

the blower can be operated with or without the rotary airlock operating. However, the

opposite situation should be prevented: the airlock should never be able to operate

unless the blower is running.

Another device, a powered bin-vent filter, is located at the top of the silo. This device

prevents backpressure in the silo and stops fugitive fines and streamers from being

released into the atmosphere. This filter should be periodically checked and cleaned.

The silos themselves should be cleaned at least annually, more often if soft products

are stored, and whenever the product stored is changed. Silo cleaning should include

a thorough washing followed by air drying before filling with resin.

Measuring the Resin in the Silo

The most common measurement techniques utilize weigh cells on the silos

themselves. While these systems provide a direct readout of the weight of material in

the bin, they can be expensive and difficult to maintain. The cost to retrofit weigh

cells to an existing silo may be prohibitive.

The level of material in the silo can also be determined by using a strapping tape,

essentially a measuring tape with a weight on the end. A pyramid-shaped weight

placed on the tape with the flat end down is often used because this shape can rest on

the surface of the pellets. Tables are used to convert the free space in the bin to

volume and then to weight.

Table 2

13

The manual strapping operation is simple, effective and inexpensive, but not as

accurate as weigh cells in good working order. Proper procedures to prevent

contamination and avoid safety hazards must be in place and enforced for all

measurement operations. Catch bars should be installed on all silo openings or hatches

to prevent falls. Proper use of safety harnesses may also be necessary.

HANDLING A DELIVERY OF PELLETS OR POWDER

RECOMMENDED SAFETY POINTS BEFORE OPENING HATCHES

“Blue flag” the track.

Understand the equipment you are about to operate. If you have any questions,

do not proceed without contacting your supervisor or an experienced co-worker.

Check for any safety risks before you begin.

Put on safety goggles, hard hat, safety shoes, protective gloves and hearing

protection if you will be working near the transfer units.

Secure the hopper car. Set the hand brake, derails, chocks, “Car Connected”

signs, etc., so the car cannot be moved during the unloading process.

Place catch trays or tarps around the delivery area to contain spills and meet the

requirements of Operation Clean Sweep (see page 4). An alternative is to pave

all unloading areas for easy cleanup.

Inspect the hopper car to make sure no seals are broken and there is no damage

to the car. The packing list for the car provides a list of seal numbers and the

volume of resin of the car. Any problems with seals or car damage should be

reported immediately to your LyondellBasell customer service representative. Do

not unload the car until the delivering railroad agent has been notified and you and

the agent make a joint inspection.

Make sure ventilation is adequate. Some resins have residual odors, which may

be objectionable.

If you have to climb on top of the railcar, you must protect yourself from falling off

the car. If the car is not located in a building with a safety handrail system, make

sure you are wearing a safety harness attached to a cabling-fall-protection

system or a stationary rail to catch you if you fall.

Attach a ground wire to the car and ground all metal handling systems. Non-

metal containers can be grounded by placing a grounding rod in the resin.

Make sure the unloading system is set up so the unloaded resin is sent to the

proper location.

STATIC ELECTRICITY

The need for grounding is based on the fact pellets accumulate static charges during

transfer and handling, which normally are little more than a nuisance. The lining of the

car prevents the charges from dissipating. However, people sampling the hopper car

through the hatch should be aware static charges are present. While the shock does not

kill, sudden movements after a shock could lead to injuries; if, for example, the person is

on top of the car and does not have a harness properly attached to a stationary bar.

One way to prevent shocks during sampling is to momentarily rest the handle of the

sampler on the hatch and then push the sampler into the pellets.

14

PREPARING THE HOPPER CAR FOR UNLOADING

After safe access to the top of the car has been established . . .

Figure 11. Hopper car delivery: inspect-

ing the unloading tube and

placing a filter and catch pan.

Courtesy of Dyna-Bulk, Inc.

Make sure you are wearing clean, rubber gloves when taking samples and that

the containers for the samples are clean.

Wipe the valve outlet with a clean cloth.

Take the sample and replace the shield and valve caps if the car is not to be

unloaded immediately.

Recheck the hook-up to make sure the product will be transferred to the correct

storage silo.

If the compartment will not be completely unloaded that day, close all outlets and

hatches to prevent contamination and vandalism.

Reseal the compartments.

UNLOADING THE HOPPER CAR

Hoses

Stainless steel hoses are preferred. Clear plastic hoses are commonly used, but

must be checked often for abrasions, breaks and distortion.

Make sure the hoses are clean. Between deliveries, hose ends should be covered

to prevent contamination. Pellets and fines can catch at hose end fittings and can

cause contamination of future deliveries, unless hoses are cleaned before and

after unloading.

Cut seals and open the hatch on the

compartment to be unloaded.

Opening the hatches is not

necessary on vented cars.

Visually inspect the product in each

compartment. Report any

contamination, such as water,

different-looking resins, dirt, leaves,

insects, etc.

Inspect the hatch opening and

install a filter over each opening to

prevent contamination from dirt,

water, etc.

Remove both caps on the unloading

tube and the plastic valve inserts.

Inspect and clean the tube and

place a filter on the end that is not in

use (Figure 11).

If there is no obvious contamination,

take samples.

15

Make sure metal hoses are set up so the product is flowing in the direction of the

coils or spirals. If the product flows in the “wrong” direction, the resin could

abrade and fines could result. Most hoses are marked to indicate the direction

for correct set-up. LyondellBasell recommends that operators do not stand on the

hoses. This action can shorten hose life and is also a safety hazard.

Hook transfer hoses onto the outlet valve of the hopper car (Figure 12) or hopper

truck (Figure 13). Make sure the hoses are not lying in water or on dirt, as

contamination could be pulled into the system from these sources.

All sources of air drawn into houses and conveying system must be filtered to

prevent dirt, dust and other contamination from entering the system.

Hoses must be grounded.

Minimize the number of bends in the flexible hose as bends add to the pressure

drop in the conveying system and can lead to plugging of the lines.

Figure 12. Hopper car delivery: hooking up the

hoses.

Courtesy of Dyna-Bulk, Inc.

Figure 13. Basic components of an adjustable

pneumatic outlet.

16

Venting

Make sure roof hatches and tubes at the bottom are opened and covered with

filters. If present, remove the plastic film underneath the hatch cover as well as

the plastic valve inserts in the unloading tubes. If these “vents” are not opened

and unloading occurs, the roof of the hopper car could collapse, resulting in

expensive repairs. Properly handling bulk deliveries lessens these costs.

Vented hatch covers can be found on some hopper cars. These cars have air inlets on

the hatch covers that allow the car to “breathe.” The construction of the car is protected

and load condensation is reduced as a result. Stenciling on the car identifies cars with

vented hatch covers. Hatch covers on vented cars do not need to be opened before

unloading.

Plant Transfer System

When prevention of contamination from a previously conveyed material is

necessary, wash out and dry by blowing air on parts of the transfer system,

particularly the cyclone, airlocks, chutes, etc., to remove dust and pellets from

previous deliveries. Make sure these areas are dry before unloading.

After Unloading Each Compartment

As each compartment empties, the flow rate goes down because air is being

drawn into the control valve and the vacuum is decreasing. At this point, rotate

the valve to remove product from the side of the compartment closest to the

valve. The flow rate should go back up to the set level. When the flow rate goes

down again, move the valve back and forth in the compartment to remove all of

the resin.

Shut off the transfer system.

Disconnect the hose from the outlet for the

unloaded compartment. (NEVER

disconnect the hose until you have

shut off the blower.)

Close the control valve.

After establishing safe access to the top of

the hopper car, make sure the

compartments are empty by removing the

hatch filter and LOOKING THROUGH

THE TOP HATCHES WHILE SHINING A

FLASHLIGHT OR WORKLIGHT INTO

THE CAR (Figure 14.

Figure 14. Hopper car delivery:

making sure the compart-

ments are empty.

17

DO NOT use probes to remove bridged material from the car walls or bang on

the car walls with heavy objects. These actions can damage hopper cars and

their linings, requiring expensive repairs. If bridging occurs, contact your

LyondellBasell customer service representative for technical advice.

Disconnect the transfer system from the hopper car’s discharge outlet.

Remove filters.

Make sure the valve is closed and all discharge outlets are capped and secured.

Remove catch trays or tarps and properly dispose of any spilled material.

Put filters on the openings of the next compartment to be unloaded.

Attach the hose to the next compartment’s outlet and start the blower.

Check the transfer pressure and get up to the desired transfer rate.

Repeat this procedure with each compartment in the hopper car.

Make sure both sides of the hopper car compartment have been emptied, both

the “near side” and the “far side.”

After the Car is Completely Unloaded

Close hatches and bottom tubes and reinstall the caps on the tubes and valves.

Prepare “Empty Return” bill of lading.

Notify railroad agent to pull the railcar as soon as possible.

18

Unloading Checklist

Are derails, hand brakes, chocks set around the hopper car?

Have “Car Connected” signs been placed to prevent accidents?

Has the car been inspected for damage or vandalism?

Are all the seals intact?

Is this the correct hopper car for the selected resin silo?

Is the unloading system cleaned and purged? Purge the system with

50 pounds to 100 pounds of product before loading the silo to make

sure the system is clean. Contain and properly dispose of the purged

material.

Has the roof hatch on the compartment to be unloaded been opened

to prevent the railcar from collapsing?

Have you inspected the contents of each compartment?

Have air filters been placed on both the top and bottom hatches on

the compartment to be unloaded?

Have hoses been inspected to make sure they are clean?

Are both the inside and the outside of the hoses dry?

Have catch trays or tarps been placed under the outlet?

Has a transition piece been attached between the hose and the

hopper car opening if the hose has a diameter smaller than six

inches?

Has the control valve been opened and adjusted so the flow rate is

correct? (The easiest way to maintain the flow rate is to remove

product from the far side of the compartment first. Heavier flows

result in higher transfer temperatures, which can lead to problems.)

After unloading one compartment, has the blower been turned off

before disconnecting the hose?

Have filters been placed on the next set of hatches and openings?

After unloading the car entirely, has the valve been closed?

Has the transfer system been shut off?

Has the railcar been VISUALLY inspected to make sure all product

has been removed?

Have all the roof hatches been closed and locked down?

Has the transfer system been disconnected from the hopper car’s

discharge outlet?

Have filters been removed?

Have caps been placed on all discharge outlets (both sides)?

Have the ends of the hoses been checked for loose pellets or fines

and these items removed?

Have the ends of the hoses been covered to keep them free from

contamination?

Has the railroad agent been notified to remove the railcar?

19

DIFFERENCES BETWEEN HOPPER TRUCK AND HOPPER CAR UNLOADING

Instead of using the vacuum system generated by the in-plant transfer system, hopper

trucks are unloaded using the air blower on the truck itself. This blower is driven by

either the tractor engine or by a remote engine (Figure 15).

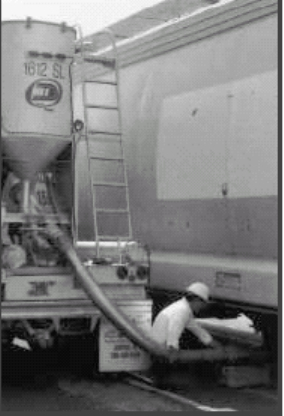

Figure 15. A hopper car is unloaded

into a hopper truck for

shipment to a customer

not serviced by a rail

line. The truck’s air

blower is used to unload

the car. Note that the

conveying pipe does not

touch the ground to

prevent moisture and

contamination from

entering the system.

Courtesy of Dyna-Bulk, Inc.

Hopper truck unloading sites should be as close

to the silo as possible. Air temperature must be

kept as low as possible. An after-cooler is

recommended when conveying temperatures

exceed 100°F.

The unloading hose for hopper trucks has a

diameter of four inches, so the connection for

the transfer system should also be four inches

in diameter.

The dense-dilute phase unloading process is

recommended for unloading a hopper truck. The

objective of this process is to put as much

product into the line and use the smallest

volume of air possible to move this amount of

product. The desired velocity is just above the

velocity at which the line begins to plug. Even

though unloading systems can produce higher

air velocity, the dense-dilute phase process

takes no longer to empty the truck. The

increased amount of material moving through

the line more than compensates for the lower

velocity—and the creation of fines and

streamers is minimized through lower air

temperatures.

GAYLORD BOX HANDLING

Maintaining dust-and-dirt-free storage and production areas is the most important way to

avoid contamination of the resin that can lead to production problems.

Brush off the top of the Gaylord box before moving it to the production area.

In the production area, remove the lid from the box and take the lid away from the

production area. For dusty production areas, special covers that minimize

contamination, while allowing for unloading, are available for gaylords.

Carefully open the liner.

At this point, personnel trained in procedures that prevent contamination should do

necessary sampling.

Wipe the feed mechanism with a clean, lint-free cloth before putting it into the

Gaylord box.

Remove all empty Gaylord boxes from the production area as soon as possible.

Static charge can build up on transfer hoses. Grounding of the hose may be

necessary.

20

50-POUND BAG HANDLING

SPECIAL HANDLING FOR LYONDELLBASELL PERFORMANCE POLYMERS

ETHYLENE COPOLYMERS

WIRE AND CABLE RESINS AND COMPOUNDS

21

POLYOLEFIN POWDERS

Microthene

®

polyolefin powders for rotational molding are ground to a nominal mesh

size of 35 (nominal 500 micron). The bulk density of powders is lower than that of

pellets, but transfer systems used for pellets can be used without modification for

powders. The angle on the silo cone and hoppers should be 60 degrees or more from

the horizontal. All systems should be dust-tight and electrically grounded, as with pellet

systems.

Microthene F Microfine polyolefin powders for coatings, low profile additives and other

specialty applications can be delivered in 50-pound bags, 500-pound “Supersacks” and

500-pound boxes. These powders have an average diameter of 20 microns. All of the

recommendations for bag and box handling apply, along with the special considerations

for powders mentioned above.

While microfine powders have been classified as only a “nuisance dust,” according to

the Occupational Safety and Health Administration (OSHA), they are flammable if

ignited. It is essential that all unloading systems are grounded, as noted previously,

and all potentially spark-producing equipment is removed from the unloading area.

See Appendix 2 for safety and handling information for these powders.

Quality Assurance

Throughout this manual, we have discussed recommendations for preventing resin

contamination. Resin contamination can occur any time during the delivery, handling,

transfer and storage process. Therefore, preventing contamination must be part of

every stage in the process.

Cleanliness is the first and easiest step. All parts of the in-plant transfer system must be

clean and dry. As there are regularly scheduled downtimes for maintaining production

equipment, so should there be regularly scheduled downtimes for the inspection and

cleaning of transfer equipment. Just the simple procedure of cleaning out lines with

blowing air goes a long way toward preventing fines and streamers from developing and

contaminating future deliveries. Regular cleaning of transfer lines also finds leaks in the

system and prevents expensive resin loss. Regular inspection and cleaning of silos is

equally important.

Fines and streamers can also be reduced by:

1. Paying attention to the temperature and velocity of the transfer blowing air,

particularly with very temperature-sensitive resins.

2. Utilizing piping with specially treated interior walls.

3. By designing transfer systems that are as short in length as possible with a minimum

of bends and no tipped sections.

Each of these recommendations is discussed in greater length earlier in this manual.

22

MEETING THE GOALS OF OPERATION CLEAN SWEEP

Plastic pellets inadvertently lost at plastic production and warehouse facilities have

increased as much as 400 percent in recent years in widely separated locations. These

pellets pose a threat to fish and wildlife. The U.S. EPA has classified plastic pellets as

“significant materials.” The finding of even one pellet in storm water run-off without a

permit is now subject to federal regulatory action with the potential for substantial fines

and penalties.

Operation Clean Sweep is a plastics-industry-wide effort to prevent the accidental

release of pellets into the environment and to improve the public’s perception of our

industry. Specific recommendations for handling polyolefins to prevent resin loss into

the environment have been developed as part of the program, Operation Clean

Sweep. See http://www.opcleansweep.org/ for more information.

Those recommendations include: Enlist the aid of employees by:

Establishing written procedures focused on reducing and recovering spilled

resins.

Conducting educational awareness programs for employees to sensitize them to

the need to prevent pellet loss.

Assigning designated employees specific responsibilities for monitoring and

managing pellet retention.

Using teamwork to solve problems and build a consensus of commitment to this

task.

Establishing standard procedures and making sure the proper cleanup tools and

materials are readily available.

Establishing personnel responsibilities by making the cleanup the responsibility

of the person(s) causing the spill and insisting on immediate cleanup.

Developing a system for recovered pellets to be recycled or otherwise used in a

manner that prevents their escape into the environment.

Unloading and sampling operations are the prime sources of accidentally spilled pellets.

To repeat some points made earlier in this manual:

Pave unloading areas to facilitate the cleanup of pellets, or use a tarp or catch

tray to collect spilled pellets.

Keep unloading areas swept or vacuumed.

Anticipate the result of rain or flooding by using a collector grate and filtered

storm drain system.

When sampling from the bottom of a hopper car, be sure the outlet cap is

properly reinstalled and sealed.

When sampling from the top of a hopper car, use wide-mouthed containers or

polyethylene bags.

Thoroughly unload hopper cars and trucks and cycle the outlet valve while air is

flowing.

23

Visually confirm the compartment is empty before closing all valves and

securing outlet caps and hatches.

Purge lines before unhooking hoses; lift hoses to assist in the purging process.

Close outlets on compartment before shipping.

Externally clean bulk containers before releasing them.

Unloading problems increase the risk of spilling pellets. Clogged hoses, bridging of the

resin and surges in the unloading lines are common problems. To prevent these

problems, consider:

Eliminating transfer system air leaks and/or increasing the capacity of air

conveying systems to prevent plugging.

Adding loading nozzle interlocks to prevent transfer spills.

Including a bag house or filter-bag assembly on packaging and transfer lines.

If your resin is delivered in Gaylord boxes or 50-pound bags, you have a somewhat

different set of problems concerning pellet release because these packages are

moved around often as they are transferred from the truck to the warehouse and

finally to the production area. Here are some suggestions to avoid pellet loss:

Make sure forklift operators are trained in preventing damage to boxes and bags

as well as in cleanup procedures.

Check the length of the forks on the forklift to make sure they do not extend

beyond the pallet. If the forks do extend that far, they can cause damage to an

adjacent carton.

Inspect the product as it is unloaded.

Tape any damaged bags.

Place catch trays between the dock and tractor-trailer at the shipping/receiving

bay.

Thoroughly empty all bags and boxes: collect, handle and store empty bags and

boxes with care to prevent the loss of any remaining pellets.

Dispose of bags and boxes by recycling, incineration or in a well-managed

landfill.

LyondellBasell is a supporter of Operation Clean Sweep and more information about this

program is available at http://www.opcleansweep.org. For further suggestions and

assistance concerning resin transfer systems, handling procedures and storage,

contact your LyondellBasell polyethylene, performance products or wire and cable sales

representative, who can connect you with a specialist at LyondellBasell headquarters or a

plant location.

24

Problem

Line Plugs

Streamers

Probable Causes

Air velocity below saltation

point

Reduction in conveying air

Receiver vessel full

Material build-up

Improper line configuration

Friction-induced smearing on

pipe walls

Suggested Course of Action

Increase air volume

Ensure that inlet air filters are clean

Check for leakage through couplings,

line wear holes, valves, diverters,

crushed hoses, worn rotary feeders or

relief valves at air supply

Inspect air supply blower or fan motor,

drive belts, bearings and impellers for

damage or wear

Ensure that receiver filters are clean

Check for bridging in receiver vessel

cone

Replace or repair discharge feeder if

undersized or worn

Ensure air is cooled for tacky materi-

als, such as ethylene copolymer

resins

Eliminate sources of moisture which

will cause fines to agglomerate

Avoid using more than two consecu-

tive changes of direction

Avoid long-radius bends, horizontal to

vertical, near the pick-up point

Have interior surface of lines

roughened

Pellet Conveying Troubleshooting Guide

This guide is presented as general information only. For specific solutions to

pellet conveying problems, check with a reputable dealer concerning design

problems and possible changes.

APPENDIX 1:

25

Cool down the conveying air to

prevent softening of polymer, particu-

larly for ethylene copolymer resins

Reduce air velocity as much as

possible without going below the

salation point; the ideal pick-up

velocity is 4,500 fpm

For long transfer lines, reduce air

velocity in the last 40 feet by increas-

ing line diameter

Avoid cyclonic separation into

receiver vessel; allow material to free

fall

Install blinded tees or other specialty

elbows designed to minimize creation

of fines and streamers

Install elutriator, multi-pass separator/

respirator, scalperator or deduster for

streamer removal (generally done

only for large volumes)

Check resin supply at top of incoming

railcar, or draw sample directly from

truck, box or bags

Install wedged or baffled entry rotary

feeder so feeder pocket does not

operate full

Check for wear on vane tips of rotary

feeders and assure proper clearance

between the vane tip and the housing

Install blinded tees or other specialty

elbows designed to minimize creation

of fines and streamers

Occurrence is minimal; install an

elutriator or deduster if problem is

significant

Check incoming resin supply for

improper pellet cut

Operate at minimum possible air

velicity

Use wear-resistant materials,

particulary at bends

Pellet clipping by rotary feeder

Pellet breakage from long-radius

elbows

Pellet breakage from contact with

roughened lines

High velocity

Materials of construction

Fines

Excessive line or

bend wear

Appendix 1 (Continued)

Problem Probable Causes Suggested Course of Action

26

Appendix 1 (Continued)

Problem

Rotary feeder

wear

Material receiver

or dust collector

wear

System pressure

fluctuations

Inadequate

capacity

Resin cross-

contamination

Probable Causes

Elbow type

Piping configuration

High transfer pressure

Feeder type

Pellet momentum

Pellet feed problem

Receiver vent plugged

Relief valve leaking

System pressure

Line size

Piping configuration

Material hold-up in

transfer system

Suggested Course of Action

Use blinded tees or other specialty

elbows where needed

Minimizer number of bends in transfer

system

Operate at minimum transfer system

pressure

Use double feeder system, one as a

feeder and one as an air lock

Use high performance feeder with

tapered or replaceable blade tips

Avoid tangential entry

Install flapper plate in receiver bin and

allow pellets to impact flapper instead of

the far bin wall

Increase line diameter prior to vessel to

reduce pellet velocity

Check vent line from rotary air lock

Check for bridging at feed point or

streamer build-up at feeder discharge

Ensure that receiver vent filters are

clean

Check valve seat for plugging or wear

Avoid operation near valve set pressure

Maximize system operating pressure

Increase line size at end of system

Minimize length of flexible hoses

Minimize number of bends

Eliminate upward sloping lines

Completely purge system before

changing resin types

Avoid low-point pockets in line

configuration

Avoid use of tee-bends for tacky resins,

such as ethylene copolymer resins

27

APPENDIX 2:

Safety and Handling Information for Microthene F Microfine

Polyolefin Powders

Polyolefin dust is defined as a combustible material in the “Standard for the Prevention of Dust

Explosions in the Plastics Industry” (NFPA 654). Concentrations of polyolefin powder as low as

0.02 oz/ft

3

can burn, releasing sufficient heat to produce a self-propagating reaction that canresult

in an explosion.

CAUTION: Users of polyolefin powders should be aware that the explosive concentration is

dependent upon the particle size of the powder and upon any substance that may be added to it.

Users with questions concerning the explosive capability of polyolefin powders should evaluate

their particular composition and operations.

Since polyolefin powder can burn or explode, special care must be exercised when working with

the powder to ensure all sources of ignition, such as heat, sparks, flames and static electricity,

have been eliminated from the workplace. Specific standards have been developed by the

National Fire Protection Association (NFPA 33, NFPA 68, NFPA 70 and NFPA 654) for the proper

handling of dusts with inherent combustible/explosive properties. All operations involving the use

of polyolefin dusts should conform to these standards.

Polyolefin dust is currently classified as a nuisance material. These materials have a long history

of safe use and are not thought to produce irreversible change in lung tissue or produce

significant disease or toxic effect when exposure is kept under reasonable control. The

Occupational Safety and Health Administration (OSHA) and the American Conference of

Governmental Industrial Hygienists (ACGIH) have established permissible exposure limits of 15

and 10 mg/M

3

of air, respectively, for total nuisance dust, and 5 mg/M

3

for the respirable fraction.

Although polyolefin dust is classified as a nuisance dust, good industrial hygiene practices should

be followed to prevent avoidable exposures. In any situation, the exposure level should be kept

below the OSHA standard. Particle size distribution measurements of Microthene F powders

indicate a percentage of the particles are respirable, with approximately 30 percent to 55 percent

of the particles having a diameter of 10 microns or less. Since dusts having a diameter of 10

microns or less are theoretically capable of deposition in the lungs, exposures to these powders

should be minimized.

Minimizing exposure should be done, where possible, by designing the processing equipment to

prevent the release of dusts into the workplace. Where processing equipment cannot be

completely enclosed, the best alternative is the use of mechanical ventilation to collect and

control the dusts at the point of generation. Good housekeeping practices should be instituted to

augment dust control and to ensure that dust in the workplace is not available from accumulation

on the floor, the machinery or other structures. Vacuum cleaners of an approved type for

combustible dust applications, or fixed pipe suction systems with a remotely located exhauster

and collector should be used for cleaning.

If airborne concentrations of polyolefin dust cannot be reduced to acceptable levels, workers

should be protected by respiratory equipment. Care must be taken to select a respirator

applicable for the purpose intended. In the case of nuisance dusts, either an air-purifying

respirator with adequate filtration or an air-supplied respirator may be used, depending on the

airborne concentration of the particulates. When using respiratory protection, only NIOSH/OSHA-

approved respirators should be selected. Additionally, all aspects of the respirator program

should be thoroughly reviewed and approved by a competent health or safety professional.

28

APPENDIX 3:

Trade Names for Products of /\RQGHOO%DVHOO Chemicals, LP

Aquathene

®

Ethylene Vinylsilane Copolymer Resins

Alathon

®

High Density Polyethylene Resins

Flexathene

®

Thermoplastic Polyolefin Resins

Integrate™ Functionalized Polyolefin Resins

Microthene

®

Powdered Polyolefin Resins

Petrothene

®

Polyethylene and Polypropylene Resins

Petrothene

®

Select Polyethylene Resins

Plexar

®

Tie-Layer Resins

Ultrathene

®

Ethylene Vinyl Acetate (EVA) Copolymer Resins

2

The information in this document is, to our knowledge, true and accurate. However, since the particular uses and the

actual conditions of use of our products are beyond our control, establishing satisfactory performance of our products

for the intended application is the customer’s sole responsibility. All uses of LyondellBasell products and any written or

oral information, suggestions or technical advice from LyondellBasell are without warranty, express or implied, and are

not an inducement to use any process or product in conflict with any patent.

LyondellBasell materials are not designed or manufactured for use in implantation in the human body or in contact with

internal body fluids or tissues, LyondellBasell makes no representation, promise, express warranty or implied warranty

concerning the suitability of these materials for use in implantation in the human body or in contact with internal body

tissues or fluids.

More detailed safety and disposal information on our products is contained in the Material Safety Data Sheet (MSDS).

All users of our products are urged to retain and use the MSDS. An MSDS is automatically distributed upon purchase/

order execution. You may request an advance or replacement copy by calling our MSDS Hotline at (800) 700-0946.

Acrythene, Alathon, Flexathene, Integrate, Microthene, Petrothene, Petrothene Select, Plexar and Ultrathene are

trademarks owned or used by the LyondellBasell family of companies.

ABOUT US

LyondellBasell (NYSE: LYB) is one of the largest plastics, chemicals and refining

companies in the world. Driven by its employees around the globe, LyondellBasell

produces materials and products that are key to advancing solutions to modern

challenges like enhancing food safety through lightweight and flexible packaging,

protecting the purity of water supplies through stronger and more versatile pipes,

improving the safety, comfort and fuel efficiency of many of the cars and trucks on the

road, and ensuring the safe and effective functionality in electronics and appliances.

LyondellBasell sells products into more than 100 countries and is the world’s largest

producer of polymer compounds and the largest licensor of polyolefin technologies.

More information about LyondellBasell can be found at www.LyondellBasell.com.

5409/21/11

lyondellbasell.com