Compensation Cable

Installation Guide

FOR WHISPER-FLEX® AND WIDE-LOOP STEADI-FLEX® CABLES

VERSION 1114

WHISPER-FLEX® compensating

cables are designed to be used in

free-hanging applications in traction

elevators.

STEADI-FLEX® compensating cables

are designed to be used in free-hang-

ing applications in traction elevators

when a wider loop is desired.

With proper dampening devices, they

may be operated at speeds of up to

700 ft/min • 3.56 m/sec (speeds up

to 350 ft/min • 1.8 m/sec without

them). Recommended operating

temperatures from 5°F to 140°F •

-15°C to +60°C.

Important! Please read!

WARRANTY AND SAFETY INFORMATION

This guide has been prepared

to instruct installers in the safe

and efficient installation of

Whisper-Flex and Steadi-Flex

compensating cables. Failure

to follow these procedures will

not only invalidate product war-

ranty, but could endanger public

safety. If you have any ques-

tions regarding installation pro-

cedures, please do not hesitate

to call Draka Elevator Products

at 877.372.5237 or 252.972.6000.

1

Whisper-Flex® and Steadi-Flex® - the differences 2

Hardware required for installation 3

Visual inspection and moving the reel 4

Position the cable for unreeling 5

Install the counterweight support bracket 6

Prepare the cable end for termination 7

Attach the cable to the counterweight bracket 8

Whisper-Flex® cable loop diameters and installation diagram 9 - 10

Steadi-Flex® cable loop diameters and installation diagram 11 - 12

Attach the car support bracket 13

Secure U-bolt and place the S-hook 14

Determining which installation kit to use (JCC vs JCC-CHN) 15

Installing Whisper-Flex with the JCC kit 16 - 17

Installing Steadi-Flex / shallow pit installations with the JCC-CHN kit 18

Attach the cable to car support bracket 19

Multiple compensating cables installation 20

High speed installations 21

Using damping devices 22 - 25

Final inspection 26

Using the Whisper-Flex Strip Kit 27 - 32

Table of contents

2

Whisper-Flex cable provides smooth

operation at temperatures of -15° C

to +60° C and, in the US, can be used

for elevators with rated speeds of no

greater than 3.56 m/sec • 700 ft/min.

Support brackets, U-bolts, S-hooks,

and heavy duty stainless steel grips

specifically designed for Whisper-Flex

cable must be used to ensure safe

installations.

Draka Elevator damping devices are

recommended to minimize cable

sway for car speeds above 1.8 m/sec •

350 ft/min.

Steadi-Flex cable is a wide-loop

version of our standard Whisper-Flex

compensating cable.

Because of its wider natural loop,

Steadi-Flex cable can be positioned

closer to the car’s centerline. This

improves car balance and ride quality

for installations with side counter-

weights and long hang lengths (over

122 m • 400 ft).

When choosing Steadi-Flex, give

special consideration to the dynamic

loop width. The dynamic loop width

is the width of the loop when the

cable is in motion and will vary with

car speed, distance between support

points and other factors.

Whisper-Flex® and Steadi-Flex® - the differences

TAILORED FOR YOUR PARTICULAR APPLICATION

Steadi-Flex is NOT a

one-for-one replacement

for Whisper-Flex.

Pit dimension and possible

obstructions should be

considered when specifying

Steadi-Flex.

Counterweight and car

attachment points should be

spaced to match the dynamic

loop width.

3

Draka installation kits contain all

hardware needed for the safe

installation of Whisper-Flex and

Steadi-Flex compensating cable.

JCC kits are for Whisper-Flex

installations. They include a stainless

steel double eye/double weave/closed

mesh grip and one roll of electrical

tape.

JCC-CHN kits are for Steadi-Flex or

Whisper-Flex in shallow pits. They

include a 1.2 m • 4 ft chain and one or

two couplings.

BOTH kits contain

one steel S-hook,

one steel U-bolt with nuts

and washers, and

two support brackets with nuts, bolts,

flat washers and lock washers.

Hardware required for installation

USE DRAKA ELEVATOR INSTALLATION KITS

JCC kit JCC-CHN kit

Using hardware other than

Draka’s could seriously

jeopardize the safety of your

installation and void any

warranty.

4

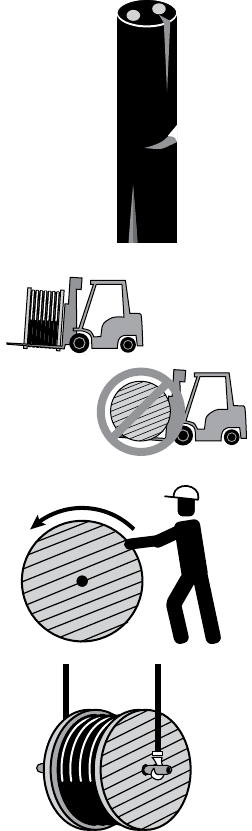

Immediately inspect the cable for

physical damage. A cut or gash could

mean a weakened and unsafe cable.

Examine the reel as well. A damaged

reel may be a sign of rough handling

in transit and may also indicate cable

damage.

Whisper-Flex and Steadi-Flex cable

may be moved by forklift.

Lift the reel by the wood, not by the

cable.

It may also be rolled on its reel on a

firm surface. If a hoist is being used,

place a strong rod through the reel for

lifting purposes. Store the cable in a

safe place.

Do not install potentially damaged

cable. Call Draka if you have any ques-

tions regarding damaged cable.

Visual inspection and moving the reel

LOOK FOR OBVIOUS DAMAGE / MOVE CABLE SAFELY

YES

NO

5

Place the cable reel in a convenient

location near the elevator (usually the

first landing or the pit floor). Reel roll-

ers are the preferred means of

supporting the reel.

Another method is to run a strong rod

or pipe through the hole in the center

of the reel. Support the pipe ends so

that the reel is off the floor enough to

rotate freely.

Pay the cable off the bottom of the

reel.

NEVER pay cable off the side of a reel

as it causes the cable to twist.

Position the cable for unreeling

WORK FROM THE PIT OR THE LOWEST LANDING

YES

NO

6

Lock washer

Flat washer

Bring the counterweight down to a com-

fortable working level. Use the counter-

weight support bracket as a template

to mark and drill correctly-sized holes

centered on the counterweight frame.

Attach the counterweight support

bracket to the frame by placing the flat

washer over the 13 mm • 1/2 in bolt and

running the bolt up through the bracket

and the frame. Then place the lock

washer on the bolt. Secure the bolt with

two nuts. Repeat with the other bolt.

Install the counterweight support bracket

DRILL THE COUNTERWEIGHT FRAME

Exploded view of

bolt/nuts/washers

7

Expose one-and-one-half links of

undamaged chain.

Both Whisper-Flex and Steadi-Flex

may be ordered with the ends prepared

as shown. Call Draka Elevator for

details.

You may also use the Whisper-Flex

Strip Kit (part number WF-STRP) to

prepare the cable end. See pages 27 -

32 for cable preparation instructions.

Prepare the cable end for termination

LEAVE ONE-AND-ONE-HALF EXPOSED LINKS

YES NO

8

Place the flat washer over the chain

attachment bolt. Run the bolt through

the chain link and the bracket. Place

the lock washer on the bolt. Secure the

bolt with two nuts.

Chain attachment bolt sizes

WF075 & 10 10 mm • 3/8 in.

WF/SFC15 to 30 12 mm • 7/16 in.

WF/SFC35 & 40 13 mm • 1/2 in.

Once the cable is attached, run the

counterweight up and bring the car

down to a comfortable working level at

the bottom of the hoistway.

Attach the cable to the counterweight bracket

USE THE ATTACHMENT BOLT SUPPLIED BY DRAKA ELEVATOR

Lock washer Flat washer

Using hardware other than

Draka’s could seriously

jeopardize the safety of your

installation and void any

warranty.

9

For optimum performance, there is a

specific distance between the cable

counterweight and car attachment

points - the cable loop diameter of a

hanging cable. As shown on the table

below, the loop diameter varies with

the size/weight of the cable.

Measured from the hanging point

of the counterweight, the cable loop

diameter provides the location of the

U-bolt.

The car support bracket is located 60 to

90 cm • 24 to 36 in. beyond the U-bolt.

Please note the JCC-CHN distances can

be reduced.

Whisper-Flex® cable loop diameters

DETERMINING LOOP DIAMETER

Product Cable Weight Loop Diameter Max. Hanging Length*

Code lb/ft • kg/m in • cm ft • m

WF075 0.75 • 1.12 22 • 54 600 • 183

WF10 1.0 • 1.49 24 • 61 600 • 183

WF15 1.5 • 2.23 24 • 61 600 • 183

WF20 2.0 • 2.98 26 • 66 520 • 159

WF25 2.5 • 3.72 26 • 66 600 • 183

WF30 3.0 • 4.46 26 • 66 505 • 154

WF35 3.5 • 5.21 27 • 69 600 • 183

WF40 4.0 • 5.95 27 • 69 530 • 162

*Max. hanging lengths are based on a 5:1 safety factor per ASME A17.1-2013

Do NOT exceed the maximum

hanging lengths shown on the

table above. Contact Draka for

longer hanging lengths.

10

Typical Whisper-Flex installation diagram

MEASURING THE HANGING POINTS

Damping

devices

Car frame center

S-hook

Mesh

grip

Cable tie

Cable Loop

Diameter

(see p. 9)

Car

Support Bracke

t

U-bolt

Counterweight

Support Bracket

Pullout switch

Safety Loop

0.6 to 0.9 meters

24 to 36 in.

Allow a

minimum of

1 m • 3 ft

Loop Diameter

(see p. 9)

This is a typical Whisper-Flex cable

installation (not to scale). The brack-

ets and U-bolt should all be in the

same plane.

Measure and mark the locations of

the car support bracket and U-bolt on

the car frame.

Two damping devices are recom-

mended for speeds above 1.8 m/sec

• 350 ft/min. See pages 22 - 25 for

details on these devices.

11

For optimum performance, there is a

specific distance between the cable

counterweight and car attachment

points - the dynamic loop width. As

shown on the table below, the dynam-

ic loop width varies with the size/

weight of the cable.

Note: at rest, Steadi-Flex cable will

bow inward slightly. If you are using

Super SwayLess devices (pages 24 -

25) to control movement, the cable

will touch the rollers at rest but will

assume the dynamic loop width in

motion.

Steadi-Flex® cable loop diameters

DETERMINING DYNAMIC LOOP WIDTH

Product Cable Weight Dynamic Loop Width Max. Hanging Length*

Code kg/m • lb/ft cm • in m • ft

SFC15 2.23 • 1.5 117 • 46 183 • 600

SFC20 2.98 • 2.0 120 • 47 159 • 520

SFC25 3.72 • 2.5 122 • 48 183 • 600

SFC30 4.46 • 3.0 125 • 49 154 • 505

SFC35 5.21 • 3.5 127 • 50 183 • 600

SFC40 5.95 • 4.0 127 • 50 162 • 530

*Max. hanging lengths are based on a 5:1 safety factor per ASME A17.1-2013

Using hardware other than

Draka’s could seriously

jeopardize the safety of your

installation and void any

warranty.

12

Typical Steadi-Flex installation diagram

MEASURING THE HANGING POINTS

Car frame

center

S-hook

Counterweight

Support Bracket

Car

Support Bracket

U-bolt

Pullout

switch

Safety Loop

0.6 to 0.9 meters

24 to 36 in.

Dynamic

Loop Width

(see p. 11)

Allow

1 m • 3 ft

At rest,

Steadi-Flex

cable will bow

inward

Super

SwayLess

damping

devices

Dynamic Loop Width

(see p. 11)

This is a typical Steadi-Flex cable

installation (not to scale - cable

bowing is also exaggerated). The

brackets and U-bolt should all be

in the same plane.

Measure and mark the locations of

the car support bracket and U-bolt on

the car frame.

Super Swayless damping devices

(pages 24-25) are recommended for

speeds above 1.8 m/sec • 350 ft/min.

Locate damping devices directly

below the counterweight support and

the car attachment points.

13

Drill properly spaced mounting holes

for the car support bracket and the

U-bolt on either side of your marks.

If using a JCC kit, the location for the

car support bracket and the U-bolt

should be 60 to 90 cm • 24 to 36 in

apart. This distance will be shorter if

using a JCC-CHN kit.

Attach the car support bracket to the

bottom of the car frame as shown.

Attach the car support bracket

DETERMINE HOLE LOCATIONS AND DRILL THEM

Car Frame

Exploded view

of bolt/nuts/

washers

U-bolt location

(less for JCC-CHN kits)

Car support

bracket location

60 to 90 cm

24 to 36 in.

13 mm • 1/2 in bolt

s

Lock

washer

Flat

washer

14

Install the U-bolt through the holes

in the car frame. Make sure that the

U-bolt is tightly held at a 90° angle to

the car frame.

Place the S-hook through the U-bolt.

The Pullout Switch should be installed

near the U-bolt. If the S-hook is acti-

vated, the cable will pull the key down-

ward and trigger the switch.

NOTE: The pullout switch kit

(WF-POSK) is sold separately.

Secure U-bolt and place the S-hook

U-BOLT SHOULD BE VERTICAL

90°

90°

Using hardware other than

Draka’s could seriously

jeopardize the safety of your

installation and void any

warranty.

15

Whisper-Flex requires the use of JCC

installation kits (or JCC-CHN kits for

shallow pits - see below). Cable termi-

nation location is determined by which

style of installation kit is being used.

JCC kits need enough cable to form

an S-shaped safety/adjustment loop

which then connects to the car support

bracket.

Once the cable has been installed and

the loop has been formed (see pages

16 and 17), cut the cable at the point

where it reaches the support bracket.

Steadi-Flex and shallow pits require

the use of JCC-CHN installation kits.

These kits use chain and couplings to

form the safety loop. Once the cable

has been installed and the loop has

been formed (see page 18), cut the

cable four links short of the S-hook.

If the cable was not ordered with

prepared ends, see pages 27 - 32 for

instructions on using the Whisper-Flex

Strip Kit.

Determine which installation kit to use

USING THE JCC OR JCC-CHN INSTALLATION KITS

Whisper-Flex uses JCC kits

Steadi-Flex and shallow pits

use JCC-CHN kit

16

For JCC installations, place the mesh

grip over the end of the Whisper-Flex

cable that will be attached to the car.

Position the grip so that the top of the

weave is between 1.5 to 2 meters • 5 to

6.5 ft from the free end of the cable.

Hang the grip from the S-hook. Adjust

the cable within the grip as needed so

that the cable hangs freely at least 15

cm • 6 in above the pit floor and forms

a ‘relaxed’ and semi-circular loop.

The cable should not bell out or hang

in a misshapen loop.

Attach Whisper-Flex to the car

USING JCC KITS WITH A MESH GRIP

1.5 - 2 m

5 - 6.5 ft

Excess

cable

Allow

at least

15 cm • 6 in.

clearance

17

For JCC installations, hang the mesh

grip from the S-hook. Compress the

mesh grip and adjust the cable so

that it forms a reverse curve (two half-

circles of equal size). Attach a cable tie

to help the cable exit the grip vertically.

Make sure the grip is hanging vertically.

The connecting cable tie for the pullout

switch should pass through the key’s

ring and the mesh grip eye loops.

Once positioned, secure the bottom

of the mesh grip to the cable with at

least 4 wraps of electrical tape. Make

sure that the safety loop does not

get caught on any pit equipment

(ex: car buffer).

Form the safety/adjustment loop - JCC kits

ADJUST AND SECURE WITH ELECTRICAL TAPE

Cable tie

Failure to make the safety

adjustment loop could

seriously jeopardize the safety

of your installation.

18

For JCC-CHN kits for Steadi-Flex and

shallow pit applications, attach the

chain provided in the kit to the cable

with the coupling (instructions are in

the coupling package).

Use the S-hook to connect the chain to

the U-bolt. If the chain link is too small

to permit this, use the second (smaller)

supplied coupling to make the connec-

tion to the S-hook.

The connecting cable tie for the pullout

switch should pass through the key’s

ring and a chain link.

The cable should not bell out or hang

in a misshapen loop.

Form the safety/adjustment loop - JCC-CHN kits

ATTACH THE CABLE WITH THE SUPPLIED COUPLINGS

Loop

diameter

Use coupling with

JCC-30-CHN and

JCC-40-CHN kits

Attach chain directly

to S-hook with

JCC-10-CHN and

JCC-20-CHN kits

0.6 to 0.9 meters

24 to 36 in.

Allow

at least

15 cm • 6 in.

Failure to make the safety

adjustment loop could

seriously jeopardize the safety

of your installation.

19

Attach the exposed link from either

the cable (JCC kit) or the chain (JCC-

CHN kit) to the bracket as shown.

Place the flat washer over the chain

attachment bolt. Run the bolt through

the chain link and the bracket. Place

the lock washer on the bolt. Secure the

bolt with two nuts.

Chain attachment bolt sizes

WF075 & 10 10 mm • 3/8 in

WF/SFC15 to 30 12 mm • 7/16 in

WF/SFC35 & 40 13 mm • 1/2 in

Attach the cable to car support bracket

TERMINATE THE CHAIN AT THE SUPPORT BRACKET

Lock washer Flat washer

20

To optimize car balance, most instal-

lations call for two equally-sized

Whisper-Flex or Steadi-Flex cables.

If so, position the brackets and the

U-bolt equidistant from the center of

the car, the same distance apart as

on the counterweight.

The cables should hang parallel to

each other and perpendicular to the

wall with the counterweight.

Multiple compensating cables installation

FOR BALANCED LOADS

Center

of car

Hanging

points are

equidistant

from center

of car

Cables

should be

of equal

weight

Steadi-Flex

installation

21

Two damping devices are recom-

mended for high-speed applications

(1.78 to 3.56 m/sec • 350 to 700 ft/

min).

Position the devices a ‘loop diameter’

apart (see page 9 for Whisper-Flex or

11 for Steadi-Flex) and directly below

the counterweight support bracket

and the Safety U-bolt/S-hook.

High speed installations

INSTALLING THE DAMPING DEVICES

YES

NO

YES

NO

All cable and support devices

should be on the same plane

within the hoistway.

The devices should not guide

the cable out of its natural

plane.

22

Two SwayLess damping devices are

normally required for installation and

are mounted 1 meter • 3 ft from the

base of the loop.

SwayLess dampeners open when

unbolted. Close the SwayLess device

around the cable and bolt it back

together. The internal brass ring can be

easily replaced as it wears over time.

Rail-mounted (SL-RMB-2) and floor-

mounting (SL-FMB-48) brackets are

available.

Using SwayLess® damping devices

FOR WHISPER-FLEX SIZES UP TO WF30 < 2.5 M/SEC • 500 FT/MIN

Damping

devices

with

mounting

brackets

Allow

1 m • 3 ft.

Damping

devices

with

mounting

brackets

Allow

1 m • 3 ft.

When properly installed,

damping devices will keep

the cable inside its vertical

traveling plane.

It is critical that the cable travel

vertically as it passes through

the dampeners.

23

Two Super SwayLess damping devices

are normally required for installation

and are mounted 1 meter • 3 ft from

the base of the loop.

Use a wrench to detach one roller with

two brackets and place the dampener

around the cable. Reattach the roller

and brackets after inserting the cable.

Rail-mounted (SSL-RMB-2) and floor-

mounted (SSL-FMB-48) brackets are

available.

Using Super SwayLess® damping devices

FOR INSTALLATIONS 2.5 TO 3.56 M/SEC • 500 TO 700 FT/MIN

Allow

1 m • 3 ft.

NO

Damping

devices

with mounting

brackets

Allow

1 m • 3 ft

YES

NO

Cable should

barely touch

inner rollers

Allow

1 m • 3 ft.

NO

Damping

devices

with mounting

brackets

Allow

1 m • 3 ft

YES

NO

Cable should

barely touch

inner rollers

When properly installed,

damping devices will keep

the cable inside its vertical

traveling plane.

It is critical that the cable travel

vertically as it passes through

the dampeners.

24

It is important to note that Steadi-

Flex cable will actually touch the roll-

ers of a Super SwayLess device when

at rest. This is due to the natural

tendency of Steadi-Flex cable to bow

inward when not in motion.

When the car moves, the cable will

assume its dynamic loop width and

touch the Super SwayLess device

as part of its normal sway damping

function.

Using Super SwayLess devices with Steadi-Flex

THE CABLE WILL TOUCH THE DEVICES AT REST

Dynamic loop

width

Car frame

center

S-hook

Counterweight

Support Bracket

Car

Support Bracket

U-bolt

Cable should

be vertical

when in

motion

Inward curve of

static loop

exaggerated for

clarity

Pullout

switch

Cable may touch

rollers at rest,

but expand to

dynamic loop

width when in

motion

25

The ShallowSwayless is ONLY for shal-

low pit applications.

The ShallowSwayless is a sway reduc-

tion device for shallow pit applications

where there is insufficient pit depth for

SwayLess or SuperSwayless devices.

It reduces compensating cable sway

and oscillation in installations up to

3.56 m/sec • 700 ft/min. Two sizes

are available; the 27L version is for

Whisper-Flex and the 50L version is for

Steadi-Flex.

The kit includes all components

shown, including mounting bolts and

washers.

Using ShallowSwayless damping devices

RECOMMENDED ONLY FOR SHALLOW PIT INSTALLATIONS

26

Give your installation a final

inspection. Make sure that:

• the cable has no cuts, gashes,

deep abrasions or damaged links

• all Support Brackets are tightly

fastened

• both end links of the cable are

securely attached to the support

brackets

• all U-bolts are vertical and tightly

fastened

• the cable hangs vertically and

does not touch walls, floor

or hoistway/pit equipment

• if damping devices are used,

make sure that they are installed

at the recommended height

above the bottom of the cable

loop

• the damping devices, if used,

do not guide the cable out of its

natural loop or interfere with

buffer operations.

• the pullout switch key is securely

attached to the mesh grip eye

loop (JCC kit) or a chain link

(JCC-CHN kit) and that it will freely

and vertically pull out should the

S-hook activate.

Final inspection

CHECK ALL POINTS PRIOR TO OPERATION

A routine inspection program should be implemented to maximize

product safety and performance.

27

The Whisper-Flex Strip Kit (WF-STRP

- ordered separately) contains all of

the tools and accessories required to

prepare both Whisper-Flex and Steadi-

Flex cable ends for installation.

The kit contains

• an angle bracket,

• clamps to fit all sizes of cable,

• nippers,

• a utility knife,

• cable jacket cutter, a hacksaw,

• protective gloves and

• a carrying case.

Replacement tools can be ordered

individually.

Prestripped cable is available.

Call Draka Elevator for details.

Cable stripping instructions

USING THE WHISPER-FLEX FIELD STRIP KIT

28

Attach the angle bracket to the car

guide rail by tightening the beam

clamps using a 3/4 inch wrench.

Position the angle bracket as shown at

a comfortable working height.

Insert the proper-sized cable clamp

into the channel.

Use a screwdriver to loosen the cable

clamp.

Attach the angle bracket to the car guide rail

SELECT THE PROPER-SIZED CLAMP

Cable goes

through clamp

Guide rail

Cable clamp

Beam clamp

Beam

clamp

29

Run the cable through the clamp so

that 7.5 to 10 cm • 3 to 4 in of cable is

exposed above the clamp. Tighten the

clamp with a screwdriver.

Position the cable jacket cutter about

7.5 cm • 3 in from the cable end.

Rotate the jacket cutter to score and

make a ring cut through the cable.

Score the jacket with the cable jacket cutter

ESTABLISH A GUIDE CUT

Extend cable

7.5 - 10 cm • 3 - 4 in.

above clamp

Score jacket

7.5 cm • 3 in.

from the end

30

Once the cable is scored,

1) grab the end of the cable and bend it

as you...

2) deepen the ring cut all the way to

the chain with the utility knife. This

may require several passes with the

knife.

3) Use the utility knife to make

a vertical cut from the ring cut to the

cable end. Make sure the jacket is cut

deeply enough to reach the chain.

Cut and slit the cable jacket

CUT ALL THE WAY TO THE CHAIN

1) pull cable away

from utility knife

2) cut until you

reach the chain

3) cut until

you reach

the chain

31

Once the ring and vertical cuts are

made, use the nippers to grab an edge

of the vertical cut and rip the jacket

from the chain. If necessary, repeat

this step for the other edge of the cut.

Repeat the stripping process as need-

ed until one-and-one-half undamaged

chain links are exposed. Discard any

cut links.

Use the nippers to remove the jacket

EXPOSE ONE-AND-ONE-HALF LINKS OF UNDAMAGED CHAIN

32

Unbolt the arm of the angle bracket

that was used to prepare the coun-

terweight end of the cable. Reattach

it so that the side with the channel/

clamp is facing up.

Tighten the clamp to hold the cable.

Use the hacksaw provided in the strip

kit to cut off the excess cable.

Clamping the cable to the angle

bracket helps prevent injury caused

by blade slippage.

Return the angle bracket arm to its

original position.

Prepare the cable end as before

(pages 7 to 12).

If you are using a JCC kit with mesh

grip, go to page 17 for safety loop

instructions.

If you are using a JCC-CHN kit with

chain, go to page 18 for safety loop

instructions.

Cut the cable to the correct length

USE THE ANGLE BRACKET AS A SUPPORT

Whisper-Flex, Steadi-Flex, SwayLess,

SuperSwayLess, ShallowSwayLess, the

Draka globe design and Draka Elevator

are trademarks of Prysmian.

Unauthorized reproduction, disclo-

sure or distribution of copies by any

person of any portion of this work

may be a violation of Copyright Law

of the United States of America and

other countries, could result in the

awarding of statutory damages of up

to $100,000 (17 USC 504) for infringe-

ment and may result in further civil

and criminal penalties.

Draka Elevator reserves the right to

improve, enhance, or modify the fea-

tures and specifications of Draka prod-

ucts without prior notification.

©2014 Draka Elevator.

All rights reserved. Printed in USA.

FOR TECHNICAL ASSISTANCE,

CALL TOLL FREE (US AND CANADA)

877.408.HELP (877.408.4357)

TO ORDER KITS/PARTS,

CALL TOLL FREE

877.DRAKA EP (877.372.5237)

Comp Install Guide 1114

Draka Elevator

2151 N. Church Street | Rocky Mount, NC 27804

1-877-DRAKA EP (877-372-5237) | +1-252-984-5100 | Fax +1-252-972-6001

Technical information 1-877-408-4357 | www.drakaelevator.com