Direct Injection 4.3 L Propane Engine

Research, Development, and Testing

Brad Zigler

National Renewable Energy Laboratory

June 13, 2019

DOE Vehicle Technologies Program

2019 Annual Merit Review and Peer Evaluation Meeting

This presentation does not contain any proprietary, confidential, or otherwise restricted information.

Project ID # ft081

Partners:

Todd Toops (Oak Ridge National Laboratory)

Sundar Krishnan (Univ. of Alabama)

Kalyan Srinivasan (Univ. of Alabama)

NREL | 2

Overview

• Project start date: July 2017

• Project end date: July 2020

• Percent complete: ~60%

Budget

• Total project funding: $3,231,643

– DOE share: $2,064,117

– Contractor share: $1,167,526

• Project funding above was based

on FOA award, subsequently

under revision

• Direct fuel injection technology is

a

technical barrier for propane

engines as they are primarily

based on gasoline engines, which

have increasingly shifted from port

injection to direct injection (DI)

• Emissions controls to enable

mo

no-fuel (vs. bi-fuel) propane

operation with DI are necessary

Timeline

Barriers

• NREL, ORNL, University of Alabama

• Industry collaboration

– Blossman Services, Inc.

– Freightliner

– United Parcel Service (UPS)

– Vieletech

Partners

FOA: Funding opportunity announcement

NREL: National Renewable Energy Laboratory

ORNL: Oak Ridge National Laboratory

NREL | 3

Relevance

• This project was originally developed as a proposal to a DOE Vehicle Technologies

Office (VTO) FOA area of interest to fund:

– Research, development, and demonstration of a direct injection (DI) propane

engine for an on-road vehicle approved for highway use...

– Includes light, medium, and heavy-duty applications…

– Based on a currently-available commercial engine...

– Include demonstration of engine in a vehicle or on a test stand and must be

combined with a vehicle simulation in the Argonne National Laboratory

Autonomie Vehicle Modeling & Simulation Platform or similar tool…

– Must meet current U.S. standards for criteria pollutants.

NREL | 4

Relevance

• An industry-led team successfully proposed:

– Research and development for mono-fuel DI propane variant of General

Motors 4.3L V6 gasoline spark ignition direct injection (SIDI) engine…

– Including critical high pressure fuel system controls for DI propane…

– Minimizing hardware changes (pistons and cylinder heads) to enable post-

project commercialization…

– Exhaust aftertreatment research and development for mono-fuel DI propane

operation, including industry guidance on particulate matter emissions…

– Meeting Environmental Protection Agency (EPA) Phase 2 medium-duty /

heavy-duty regulations…

– Demonstrating at least a 20% greenhouse gas (GHG) improvement (with a

stretch goal of 30%) over a baseline gasoline engine version on a custom drive

cycle representing package delivery truck operations…

– Integrated into a Freightliner MT-55 commercial truck…

– Demonstrated in fleet use with UPS…

– With comparative chassis dynamometer GHG studies to feed back into

Autonomie.

NREL | 5

Relevance

• After key go/no-go decision, project transitioned to a DOE lab + University effort:

– Research and development for mono-fuel DI propane variant of General

Motors 4.3L V6 gasoline spark ignition direct injection (SIDI) engine…

– Including critical high pressure fuel system controls for DI propane…

– Exhaust aftertreatment research and development for mono-fuel DI propane

operation, including industry guidance on particulate matter emissions…

• While still retaining key industry input and collaboration, the revised project still

addresses most of industry and VTO’s interests:

– Research, development, and demonstration of a direct injection (DI) propane

engine for an on-road vehicle approved for highway use...

– Includes light, medium, and heavy-duty applications…

– Based on a currently-available commercial engine…

The critical technical barriers of adapting DI technology for propane engines

with integrated aftertreatment still remains the focus of the revised project.

NREL | 6

Approach

• Identify vehicle design and performance requirements from

UPS and Freightliner

• Baseline comparative 6.0L V8 port fuel injection (PFI)

gasoline UPS truck performance, emissions, GHGs

• Baseline 4.3L V6 SIDI performance on gasoline

• Evaluate vehicle simulations with 4.3L DI propane

• Develop high pressure fuel system (pump, fuel rails,

injectors) + tank integration simulations and combustion

models to understand propane vs. gasoline differences

• Develop DI propane specific hardware and software

controls and calibration – no changes to injectors

• Develop mono-fuel propane emissions control strategy

and hardware

NREL | 7

Approach

• Conduct informative particulate matter emissions

studies

• Demonstrate capability of meeting EPA certification

requirements on medium-duty engine cycle (not an

official certification)

• Integrate prototype engine + independent engine

controls into Freightliner MT-55 truck for UPS

• Conduct chassis dynamometer studies to verify

GHG improvement

• Operate prototype vehicle in UPS fleet operations

w

ith data loggers

• Feed engine and chassis dynamometer data from

DI

propane 4.3L V6 (and comparative 6.0L V8 PFI

gasoline) to Autonomie simulations

• Enable post-p

roject potential for

commercialization (durability, certification) for

UPS type applications

NREL | 8

Approach - Milestones

Develop custom package delivery chassis dynamometer

drive cycle - December 2017 milestone

Develop initial 1-dimensional model of 4.3L high

pressure fuel system (pump, fuel rails, injectors)

- April 2018 milestone

Baseline 4.3L V6 SIDI performance on gasoline and project

DI propane engine performance - June 2018 milestone

Evaluation of 4.3L DI engine applicability -

December 2018 Go/No-Go milestone decision

The FOA project award ended, but NREL, ORNL, U. Alabama, and Vieletech (with

industry input) are continuing core research – New milestones under development.

NREL | 9

Technical Accomplishments and Progress

• Existing standardized chassis dynamometer drive cycles did not accurately represent real-

world package delivery truck drive data.

• Developing a new cycle was necessary for UPS and Freightliner to understand potential GHG

impact of the 4.3L DI propane engine versus 6.0L PFI gasoline baseline in this application.

Custom ”package delivery” chassis dynamometer drive cycle enabled relevant GHG studies

HHDDT: Heavy heavy-duty diesel truck

HWFET: Highway fuel economy test

HTUF: Hybrid truck users forum

HTUF: Hybrid truck users forum

mph: Miles per hour

NYCC: New York city composite

NREL | 10

Technical Accomplishments and Progress

• NREL’s Drive-Cycle Rapid Investigation, Visualization, and Evaluation (DRIVE) analysis tool

was applied to in-use 1 Hz data collected for 1,300 days in 90 Class 5/6 package delivery

vehicles in NREL’s Fleet DNA database (76 of 90 vehicles were UPS).

• New NREL package delivery cycle was used for this project, and the cycle itself is published.

Hz: Hertz

min: Minutes

P&D: Parcel and delivery

Custom ”package delivery” chassis dynamometer drive cycle enabled relevant GHG studies

NREL | 11

Technical Accomplishments and Progress

• NREL projected 4.3L engine torque and power using E85, with which General Motors enables

higher output in the Chevrolet Silverado. Propane DI performance was estimated to match

E85-enabled levels.

• NREL and Freightliner performed WOT vehicle simulations for projected 4.3L DI propane

versus baseline 6.0L PFI gasoline with 23,000 # GVW (~12,500 # payload... heavily loaded).

• 0-30 MPH, 0-60 MPH, and maximum maintainable speed at 3%, 6%, and 9% grade evaluated.

• 4.3L DI propane 0-30 MPH was projected at ~23% slower, 0-60 MPH at ~17% slower, and no

gradeability change... acceptable performance given the GHG benefit.

• Go/no-go decision to stop was ultimately based on unknown 4.3L durability as a medium

duty engine, risking post-project commercialization to the industry partners.

Vehicle performance was projected with 4.3L DI propane to inform go/no-go decision

E85: Ethanol flex-fuel

GVW: Gross vehicle weight

HP: Horsepower

MPH: Miles per hour

WOT: Wide open throttle

#: Pound

NREL | 12

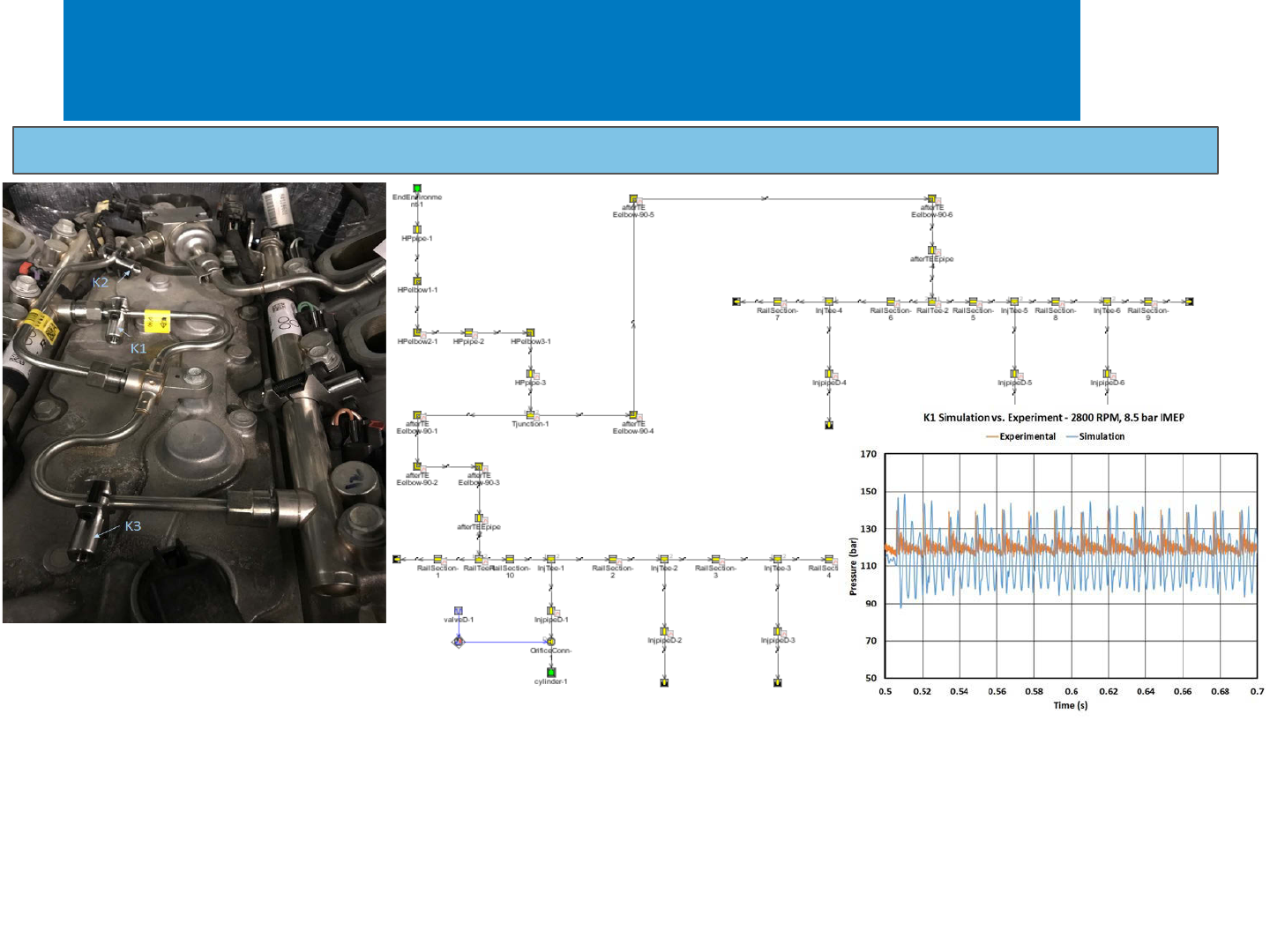

Technical Accomplishments and Progress

• University of Alabama instrumented the 4.3L high pressure fuel system to collect dynamic

response data under steady state and transient engine conditions.

• A 1-dimensional (1-D) GT-SUITE model was developed to evaluate fluid property change

effects for propane versus gasoline, guiding hardware and calibration changes required to

enable propane operation with existing injectors.

High pressure DI system dynamics for gasoline mapped and propane performance modeled

IMEP: Indicated mean effective pressure

RPM: Revolutions per minute

s: Seconds

NREL | 13

Technical Accomplishments and Progress

• University of Alabama studies on fuel system dynamics are critical to understanding

propane phase changes and thermodynamic conditions existing in the vehicle tank, the low

pressure pump, the high pressure pump, the fuel rails, and the direct injectors.

• Since Tier 1 suppliers do not yet see a market for unique propane DI injectors, production

gasoline DI injectors must be adapted with control system changes to enable their use.

• Unlike DI gasoline, conditions during shut-down, cold-start, hot soak, and hot-restart may

allow propane to become two-phase in the fuel system, leading to a loss of engine control.

High pressure DI system dynamics for gasoline mapped and propane performance modeled

NREL | 14

Technical Accomplishments and Progress

• Propane conversion at low temperatures is

required to enable mono-fuel propane DI

operation, without a “crutch” of using bi-fuel with

gasoline for the challenging cold start.

• ORNL has conducted bench-scale flow reactor

studies of new catalyst materials, in collaboration

with Umicore.

– Range of metals and functionalities included to find

most reactive formulation at low temperatures

Range of three way catalysts (TWC) synthesized to evaluate low temp. propane conversion

sample ID Description Pt (g/l) Pd (g/l) Rh (g/l) OSC NSC

ORNL-2 Pd

6.36

+Rh

0.14

w/o OSC 0 6.36 0.14 N N

ORNL-6 Pd

6.5

w/o OSC 0 6.50 0 N N

ORNL-5 Pd

6.5

with High OSC 0 6.50 0 H N

ORNL-4 Pd

4.06

with Medium OSC 0 4.06 0 M N

ORNL-3 Pd

1.41

with Low OSC 0 1.41 0 L N

Catalyst Matrix [OSC=oxygen storage capacity; NSC=NOx storage capacity]

Pd: Palladium

Pt: Platinum

Rh: Rhodium

g: Gram

L: Liter

NREL | 15

Technical Accomplishments and Progress

• Initial evaluations performed after degreening

catalyst cores

• Stoichiometric evaluation performed with

propane as the only hydrocarbon

– Can modify based on engine evaluation findings

• Catalyst with mid-level OSC (oxygen storage

capacity) showed the best reactivity for propane

• CO reactivity trends are show best reactivity

without any OSC

– TWC w/ mid-level OSC is best when OSC is present

Initial results indicate Pd-Only with a mid-level OSC loading yields best propane reactivity

Gas Concentration

C

3

H

8

1000 ppm

CO 5000 ppm

NO 1000 ppm

O

2

0.78% (stoichiometric)

H

2

1670 ppm

H

2

O 13%

CO

2

13%

N

2

Balance

GHSV 60,000 h

-1

Best

C3H8: Propane

CO: Carbon monoxide

CO2: Carbon dioxide

H2: Hydrogen

H2O: Water

O2: Oxygen

N2: Nitrogen

NO: Nitric oxide

GHSV: Gas hourly space velocity

NREL | 16

Technical Accomplishments and Progress

• NREL and Vieletech extensively mapped the 4.3L with Chevrolet Silverado production

controls on a chassis dynamometer, then transitioned to engine dynamometer studies on

gasoline with independent controls.

• Operation with production hardware provided a starting point from which to develop

propane-specific controls and calibration, guided by U. Alabama’s fuel system simulations.

• Conversion to propane operation is underway, and will include integration of a “vehicle-

like” propane storage / low pressure pump system to address key technical barriers.

Mapped baseline 4.3L DI gasoline controls from which to develop propane-specific controls

NREL | 17

Responses to Previous Year Reviewers’

Comments

This project has not previously been reviewed at a VTO

Annual Merit Review.

NREL | 18

Collaboration and Coordination

• NREL

– Conducting 4.3L engine systems research for DI propane, including

chassis and engine dynamometer experimental studies

• ORNL

– Conducting emissions controls research, including catalyst materials

evaluations and particulate matter studies

– Including a graduate student (Dae-Kun Kim) for thesis research through

the University of Tennessee (Prof. Ke Nguyen)

• University of Alabama

– Conducting experimental studies at NREL (including sending a Ph.D.

student to NREL during summer of 2018)

– Building 1-D high pressure fuel system simulations, and combustion

simulations

– Sponsoring two graduate students with this research

• Vieletech

– Under subcontract to NREL, with deep expertise in developing

independent engine controls (Dr. Matt Viele, Drivven founder)

NREL | 19

Collaboration and Coordination

• Blossman Services

– Project PI for and prime for former FOA award (under NETL subcontract)

– Continues to provide technical guidance, propane fuel system design

(vehicle side), and collaboration

• Freightliner

– Provided technical guidance, vehicle specifications, and performed vehicle

simulations for go/no-go decision

• United Parcel Service

– Provided technical guidance

– Supplied package delivery truck used in NREL chassis dynamometer studies

– Planned to operate prototype vehicle in fleet operation testing

• Umicore

– Collaborating with ORNL to provide low-temperature, propane-active

catalysts

• U. S. Environmental Protection Agency

– Providing technical exchange

– Shared 4.3L engine mapping data from prior EPA research study

NREL | 20

Remaining Challenges and Barriers

• While the project shifted away from the FOA award scope due

to commercialization drivers, the revised project focuses on

remaining key technical challenges and barriers for propane to

adopt direct injection.

• Project focus is now on deeper dive into dynamic high

pressure fuel system performance under steady state and

transient engine operation

– Transition to gas-phase within the fuel system is a major issue

– Propane thermodynamic properties differ significantly from

gasoline, and one must account for those to use gasoline direct

injectors (no propane specific injectors until industry builds

sufficient volume).

• Project focus also continues to include emissions controls and

catalyst materials that enable low temperature propane

conversion – key industry segments prefer mono-fuel.

• The revised project focuses on earlier stage research with

publication emphasis to inform industry for subsequent

commercial development.

NREL | 21

Proposed Future Research

For the remainder of this funded project:

• Finalize milestones (with DOE concurrence) for continuation of re-scoped project.

• Equip NREL’s engine dynamometer with vehicle-representative propane fuel system to

continue 4.3L propane-specific controls research.

• Link University of Alabama’s fuel system and combustion system simulations to drive

propane-specific controls.

• Continue bench-scale catalyst materials development, then scale up to couple catalyst to

NREL’s engine dynamometer.

• Collect particulate matter emissions as industry guidance for DI effects with propane.

• Link all of the above to develop propane-specific controls to provide (and publish!)

industry guidance on how DI propane barriers can be addressed through hardware and

controls changes.

With additional funding, proposed future research*:

• While this specific engine ultimately faced commercialization challenges, industry

collaboration could leverage this project as early-stage development to support another

engine platform.

• The propane industry has been asking for comparative fuel economy / emissions studies

versus baseline (gasoline or diesel) to inform Autonomie. We have a baseline gasoline

dataset already for a key Class 5/6 application from this study, and could study a current

technology PFI propane variant.

* Any proposed future work is subject to change based on funding levels.

NREL | 22

Summary

• This project began as a FOA award project to conduct research

and development for adapting a General Motors 4.3L SIDI

gasoline engine to mono-fuel propane DI operation.

• Focus was on controls and aftertreatment development with

minimum other hardware changes that would preclude post-

project commercialization.

• While the vehicle integration, certification-ability

demonstration, and fleet use testing are no longer in scope,

the remaining project still focuses on key industry challenges:

– Developing controls hardware, strategy, and calibration to

enable DI propane based on gasoline DI platforms

– Developing aftertreatment with low temperature

conversion to support mono-fuel DI propane engines.

www.nrel.gov

NREL/PR-5400-73876

Thank You

This work was authored in part by the National Renewable Energy Laboratory, operated by Alliance for Sustainable

Energy, LLC, for the U.S. Department of Energy (DOE) under Contract No. DE-AC36-08GO28308. Funding provided

by U.S. Department of Energy Office of Energy Efficiency and Renewable Energy Vehicle Technologies Office. The

views expressed in the article do not necessarily represent the views of the DOE or the U.S. Government. The U.S.

Government retains and the publisher, by accepting the article for publication, acknowledges that the U.S.

Government retains a nonexclusive, paid-up, irrevocable, worldwide license to publish or reproduce the published

form of this work, or allow others to do so, for U.S. Government purposes.

The project team members wish to thank Dr. Michael Weismiller and DOE Vehicle

Technologies Office for support of this research.