Engineering of Defense Systems Guidebook

February 2022

Office of the Deputy Director for Engineering

Office of the Under Secretary of Defense

for Research and Engineering

Washington, D.C.

DISTRIBUTION STATEMENT A. Approved for public release. Distribution is unlimited.

Engineering of Defense Systems Guidebook

Office of the Under Secretary of Defense for Research and Engineering

3030 Defense Pentagon

Washington, DC 20301

[email protected] | Attn: Engineering

https://ac.cto.mil/engineering

Distribution Statement A. Approved for public release. Distribution is unlimited.

DOPSR Case # 22-S-0821.

iii

Approved by

Stephanie L. Possehl

Acting Deputy Director for Engineering

Office of the Under Secretary of Defense for Research and Engineering

Engineering of Defense Systems Guidebook Change Record

Date

Change

Rationale

POSSEHL.STEPHANIE.LYNN.122

9383805

Digitally signed by

POSSEHL.STEPHANIE.LYNN.1229383805

Date: 2022.02.11 11:20:36 -05'00'

iv

This page is intentionally blank.

Contents

ENGINEERING OF DEFENSE SYSTEMS GUIDEBOOK

v

83BCONTENTS

1 Purpose and Scope ................................................................................................................................... 1

2 Pre-Materiel Development Decision Engineering ................................................................................... 2

2.1 Pre-MDD Mission Engineering Reviews ........................................................................................ 6

2.1.1 Mission Review ......................................................................................................................... 6

2.1.2 Concept Design Review ............................................................................................................ 9

3 Engineering Guidance for the Acquisition Pathways ............................................................................ 12

3.1 Overview ........................................................................................................................................ 12

3.2 Major Capability Acquisition ........................................................................................................ 12

3.2.1 Systems Engineering ............................................................................................................... 12

3.2.2 Software Engineering .............................................................................................................. 63

3.2.3 Specialty Engineering .............................................................................................................. 68

3.2.4 Modular Open Systems Approach .......................................................................................... 95

3.2.5 Digital Engineering ............................................................................................................... 103

3.2.6 System Security Engineering ................................................................................................ 105

3.2.7 Technical Reviews and Assessments .................................................................................... 105

3.3 Middle Tier of Acquisition .......................................................................................................... 108

3.3.1 Rapid Prototyping.................................................................................................................. 108

3.3.2 Rapid Fielding ....................................................................................................................... 118

3.4 Urgent Capability Acquisition ..................................................................................................... 124

3.4.1 Systems Engineering ............................................................................................................. 124

3.4.2 Software Engineering ............................................................................................................ 124

3.4.3 Specialty Engineering ............................................................................................................ 125

3.4.4 Modular Open Systems Approach ........................................................................................ 129

3.4.5 Digital Engineering ............................................................................................................... 129

3.4.6 System Security Engineering ................................................................................................ 129

3.4.7 Technical Reviews and Assessments .................................................................................... 129

3.5 Software Acquisition ................................................................................................................... 130

3.5.1 Systems Engineering ............................................................................................................. 130

3.5.2 Software Engineering ............................................................................................................ 130

3.5.3 Specialty Engineering ............................................................................................................ 144

3.5.4 Modular Open Systems Approach ........................................................................................ 148

3.5.5 Digital Engineering ............................................................................................................... 148

3.5.6 System Security Engineering ................................................................................................ 149

3.5.7 Technical Reviews and Assessments .................................................................................... 149

3.6 Defense Business Systems ........................................................................................................... 149

3.6.1 Systems Engineering ............................................................................................................. 149

3.6.2 Software Engineering ............................................................................................................ 150

3.6.3 Specialty Engineering ............................................................................................................ 150

Contents

ENGINEERING OF DEFENSE SYSTEMS GUIDEBOOK

vi

3.6.4 Modular Open Systems Approach ........................................................................................ 155

3.6.5 Digital Engineering ............................................................................................................... 155

3.6.6 System Security Engineering ................................................................................................ 155

3.6.7 Technical Reviews and Assessments .................................................................................... 156

3.7 Acquisition of Services ................................................................................................................ 156

3.7.1 Systems Engineering ............................................................................................................. 156

3.7.2 Software Engineering ............................................................................................................ 157

3.7.3 Specialty Engineering ............................................................................................................ 157

3.7.4 Digital Engineering ............................................................................................................... 160

3.7.5 System Security Engineering ................................................................................................ 160

3.7.6 Technical Reviews and Assessments .................................................................................... 160

Acronyms .................................................................................................................................................. 162

References ................................................................................................................................................. 168

Figures

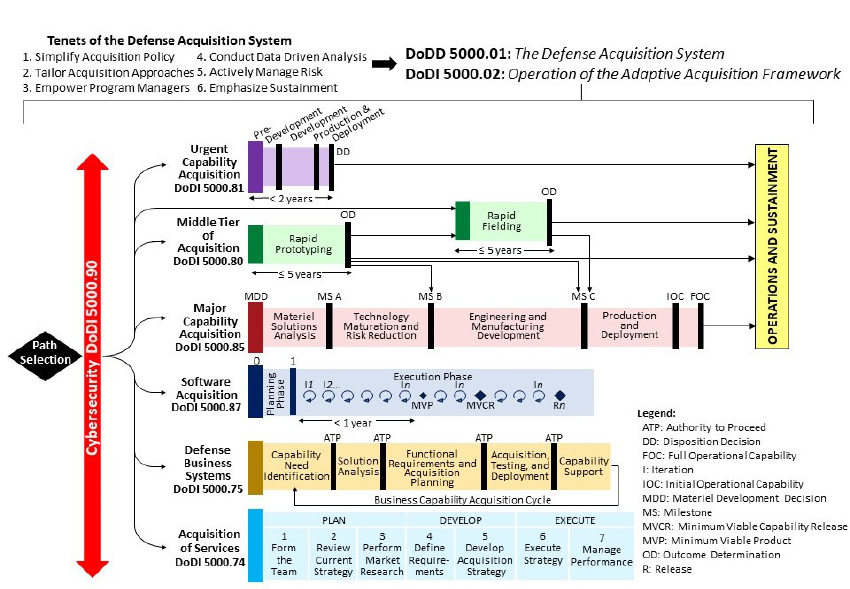

Figure 1-1. Adaptive Acquisition Framework .............................................................................................. 1

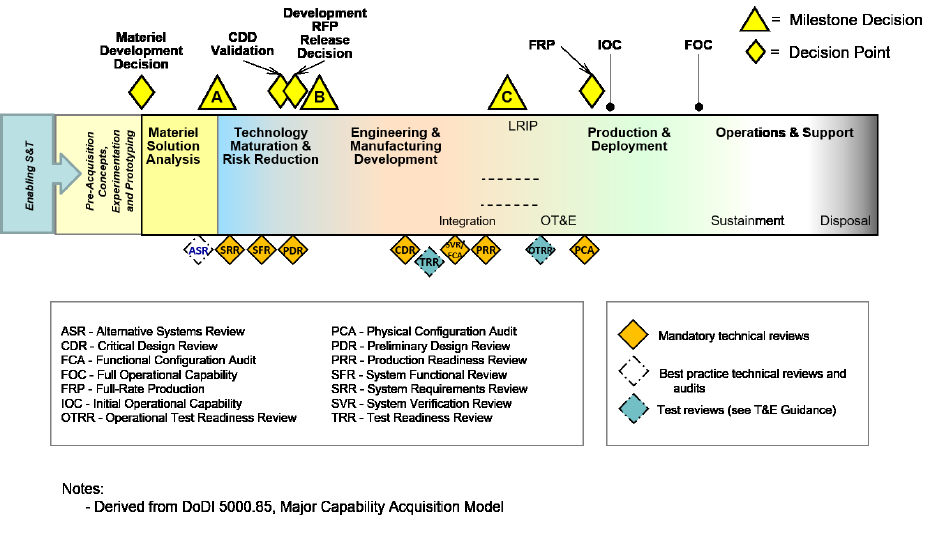

Figure 3-1. Major Capability Acquisition Life Cycle ................................................................................. 17

Figure 3-2. SoS SE Implementers’ View .................................................................................................... 18

Figure 3-3. Activities in Materiel Solution Analysis Phase ........................................................................ 23

Figure 3-4. Systems Engineering Activities in the Technology Maturation and Risk Reduction Phase .... 30

Figure 3-5. Systems Engineering Activities in the Engineering and Manufacturing Development Phase . 40

Figure 3-6. Systems Engineering Activities in the Production and Deployment Phase ............................. 51

Figure 3-7. Integration of Human Capability Considerations ..................................................................... 85

Figure 3-8. P&D and O&S HSI Challenges and Opportunities .................................................................. 87

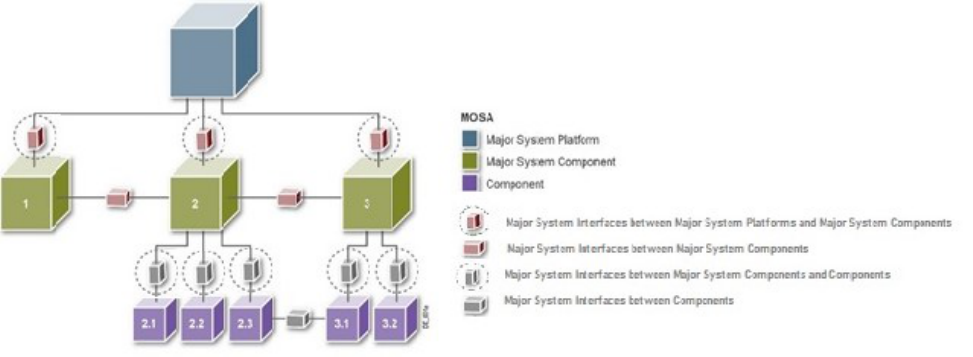

Figure 3-9. MOSA and Modular System Interfaces ................................................................................. 101

Figure 3-10. Technical Reviews and Audits for the Major Capability Acquisition Life Cycle ................ 106

Figure 3-11. Software Acquisition Pathway Phase Illustration ................................................................ 137

Figure 3-12. Business Capability Acquisition Cycle ................................................................................ 152

Figure 3-13. HSI Opportunities in the Defense Business Systems Pathway ............................................ 153

Tables

40TUTable U40T2-1. Inputs Associated with Pre-MDD ................................................................................................ 4

40TUTable U40T2-2. Technical Outputs Associated with Pre-MDD ............................................................................ 6

40TUTable U40T3-1. Technical Maturity Points ......................................................................................................... 13

40TUTable U40T3-2. Key ME and SoS Considerations for Systems by Acquisition Phase ........................................ 20

40TUTable U40T3-3. Inputs Associated with MSA Phase ........................................................................................... 26

Contents

ENGINEERING OF DEFENSE SYSTEMS GUIDEBOOK

vii

40TUTable U40T3-4. Technical Outputs Associated with MSA Phase ....................................................................... 28

40TUTable U40T3-5. Inputs Associated with TMRR Phase ........................................................................................ 33

40TUTable U40T3-6. Technical Outputs Associated with TMRR Phase ..................................................................... 38

40TUTable U40T3-7. Inputs Associated with EMD Phase .......................................................................................... 45

40TUTable U40T3-8. Technical Outputs Associated with EMD Phase ....................................................................... 49

40TUTable U40T3-9. Inputs Associated with P&D Phase ........................................................................................... 54

40TUTable U40T3-10. Technical Outputs Associated with P&D Phase ...................................................................... 58

40TUTable U40T3-11. Inputs Associated with O&S Phase ......................................................................................... 61

40TUTable U40T3-12. Technical Outputs Associated with O&S Phase ...................................................................... 63

40TUTable U40T3-13. R&M Activities by Acquisition Phase .................................................................................... 70

40TUTable U40T3-14. M&Q Activities by Phase ........................................................................................................ 79

40TUTable U40T3-15. Minimum Points (When) to Assess Manufacturing Readiness ............................................... 82

40TUTable U40T3-16. System Safety Activities by Acquisition Phase ....................................................................... 91

This page is intentionally blank.

1 Purpose and Scope

ENGINEERING OF DEFENSE SYSTEMS GUIDEBOOK

1

1 32BPURPOSE AND SCOPE

The Engineering of Defense Systems Guidebook describes the activities, processes, and practices

involved in the development of Department of Defense (DoD) systems. The guidebook aligns

with the engineering disciplines covered in DoD Instruction (DoDI) 5000.88, Engineering of

Defense Systems, and focuses on recommended engineering best practices for the DoD Adaptive

Acquisition Framework (AAF) acquisition pathways (see Figure 1-1 and DoD Instruction

(DoDI) 5000.02, Operation of the Adaptive Acquisition Framework).

This guidebook is intended for Program Managers (PMs), Systems Engineers, and other defense

acquisition professionals and may be tailored for programs in any of the AAF pathways.

Programs can use the guidebook, along with other acquisition business resources, to plan and

execute program engineering activities across the system life cycle.

Source: DoDI 5000.02

0BFigure 1-1. Adaptive Acquisition Framework

Some of the information presented in this guidebook appeared previously in the Defense

Acquisition Guidebook (DAG) Chapter 3, Systems Engineering. DAG Chapter 3 has been

replaced by this document which expands on systems engineering (SE) and other engineering

guidance as applied to the acquisition pathways to support DoD acquisition programs. The DoD

Office of the Under Secretary of Defense for Research and Engineering (OUSD(R&E)), Deputy

Director for Engineering, prepared this guidebook in cooperation with subject matter experts

(SMEs) from the Military Services, defense agencies, industry, and academia.

2 Pre-Materiel Development Decision Engineering

ENGINEERING OF DEFENSE SYSTEMS GUIDEBOOK

2

2 33BPRE-MATERIEL DEVELOPMENT DECISION ENGINEERING

The objectives of the pre-Materiel Development Decision (MDD) effort are to obtain a clear

understanding of user mission capability needs, identify a range of technically feasible candidate

materiel solution approaches, consider near-term opportunities to provide a more rapid interim

response, and develop a plan for the next acquisition phase, including the required resources.

This knowledge supports the Milestone Decision Authority’s decision to:

1. Authorize entry into the acquisition life cycle to pursue a materiel solution.

2. Select the appropriate acquisition pathway and milestone dates.

3. Define the acquisition mandates that are to be tailored and waived based on schedule and

resources.

4. Define risk acceptance authorities for schedule, cost, performance, quality, security,

testing, training, maintenance, and human factors.

Programs achieve the pre-MDD objectives primarily through Mission Engineering (ME) and

other development planning activities. Development planning includes early engineering

analyses and technical planning that provide the foundation for informed investment decisions to

meet operational needs effectively, affordably, and sustainably. Programs should initiate

development planning activities in advance of the MDD, and continue throughout the Materiel

Solution Analysis (MSA) phase for Major Capability Acquisition (MCA) programs.

ME is an iterative analysis and multidisciplinary activity in the form of studies to analyze,

organize, and integrate current and emerging operational and system capabilities to achieve

desired warfighting mission effects. ME activities in the pre-MDD phase allow programs to

characterize trade space, risks, and mission interdependencies to support the start of the Analysis

of Alternatives (AoA).

Pre-MDD policy comes from two perspectives: the Joint Capabilities Integration and

Development System (JCIDS) defined in Chairman of the Joint Chiefs of Staff Instruction

(CJCSI) 5123 and the Defense Acquisition System (DAS) defined in DoD Directive (DoDD)

5000.01.

ME and Systems Engineering (SE) are essential during early phases in acquisition to ensure

programs ultimately deliver capabilities that meet the intended needs on time and on budget.

Mission understanding, design considerations, analyses, and associated activities during pre-

MDD are critical to determine feasibility and to characterize trade space (see the Systems

Engineering (SE) Guidebook for the definition of “design considerations”). During pre-MDD,

risks in mission concept and design may emerge that will need to be addressed before the MDD

and throughout the acquisition life cycle.

The pre-MDD effort has two important aspects: (1) Establish the ME reference materials that

guide materiel solution decisions throughout the life cycle, and (2) narrow the field of possible

2 Pre-Materiel Development Decision Engineering

ENGINEERING OF DEFENSE SYSTEMS GUIDEBOOK

3

solutions to a reasonable set that engineers analyze in the AoA. ME activities are critical to

refining the options. By defining and characterizing the mission(s), the capability gaps to be

addressed in the future fight, and potential warfighter concept solutions in a structured format,

the engineers and analysts help ensure the Service appropriately trades materiel solutions and

targets the evolving needs of the battlespace. ME studies help ensure a consistent understanding

of the constraints and technical feasibility so concept developers can eliminate initial ideas that

lack the potential to meet the need in a timely, sustainable, and cost-effective manner, while

ensuring the remaining range of alternatives is sufficiently broad for the AoA. The Systems

Engineer or Requirements Manager should engage with the end user or end user representatives

before the Joint Requirements Oversight Council (JROC) validates the Initial Capabilities

Document (ICD) or equivalent requirements document and associated operational architecture as

described in the SE Guidebook.

The Government Accountability Office (GAO) has found that “programs that considered a broad

range of alternatives tended to have better cost and schedule outcomes than the programs that

looked at a narrow scope of alternatives.” (See Government Accountability Office (GAO)-09-

665 Analysis of Alternatives, Page 6.) ME and AoA study teams can consider more alternatives

and design variations by using modeling and simulation tools.

The engineers performing pre-MDD work document all ME results so the PM and Systems

Engineer, when assigned, will benefit from an understanding of the basis of the mission, the

derived need (requirements), and the art of the possible (concepts/materiel solutions). In

addition, the program should continue to update the ME products to reflect the evolving mission

and threats. This ME analysis will then guide the PM and acquisition leadership at every

acquisition decision point to inform whether the materiel solution is still relevant to the

battlespace.

ME and SE personnel should use digital artifacts (models, simulations, etc.) from many

disciplines and across a hierarchy of perspectives that range from strategic, campaign, and

mission levels to analyze overall requirements, employment options, and battlespace efficacy.

The program should maintain, refine, and repurpose digital artifacts developed in early

acquisition phases for activities during later phases (e.g., engineering models can be used in

training simulations). Developing new digital artifacts can be costly. An option for new

development is to consider leveraging existing models and simulations, using various

interoperability standards to create needed capability. ME and SE personnel should consider how

to leverage models, simulations, and their interoperability as they plan for their use throughout a

program’s life cycle. Modeling and simulation can also support developmental test and

evaluation (DT&E) and operational test and evaluation (OT&E).

ME and SE personnel should continue to mature modeling and simulation tools used during the

pre-MDD phase and throughout the acquisition life cycle to represent the final system

configuration. Maintaining the models and simulations allows the program to perform additional

assessments as the system progresses.

2 Pre-Materiel Development Decision Engineering

ENGINEERING OF DEFENSE SYSTEMS GUIDEBOOK

4

Roles and Responsibilities

Often there is no assigned PM or Systems Engineer at this point in the system’s life cycle.

Instead, a designated Service representative (e.g., Requirements Manager) is leading the

activities prior to MDD. This leader is responsible for synthesizing the necessary information to

support a favorable decision. As a best practice, leadership should consider designating a Service

engineering representative to orchestrate or perform ME activities and support concept and

requirements definition and associated decisions in preparation for the MDD.

Digital engineering approaches including models and other digital representative products are

essential to understanding complex systems and interdependencies in this phase. Likewise, they

provide a means to explore concepts, system characteristics, and alternatives; open up the trade

space; facilitate informed decisions and assess overall system performance. Whether a program

adopts a robust digital engineering approach or not, ME analysis (see the ME Guide), models,

and simulations (SE Guidebook Section 2.2.1) are critical to quantitatively assess alternatives

and will also play a role throughout the program life cycle. The designated Service representative

should consider issuing a Request for Information to industry to help identify alternative

concepts, solutions, and their model equivalents.

Inputs

Table 2-1 summarizes the primary inputs associated with pre-MDD. Unlike the acquisition

pathways that follow, this period is the bridge between JCIDS and the DAS.

1BTable 2-1. Inputs Associated with Pre-MDD

Inputs for Pre-MDD

Mission definition artifacts:

Future time frame in which the mission is set

Future threats/adversary capabilities

Scenario details

Mission objectives, constraints, and measures of success

Expected and alternative force laydown(s)

Laws, mandates, policies, Executive Orders

Other program needs/failures

Lessons learned

Joint Warfare Capability definitions gaps; Service Component capability area definitions and gaps

USD(R&E) Technology Modernization roadmaps

Draft ICD or equivalent (See CJCSI 5123)

Product of Capability-Based Assessment or equivalent

Other analyses

Other prior analytic, experimental, prototyping and/or technology demonstration efforts may be provided by the

science and technology community

Results of market research: (1) to identify existing technologies and products; and (2) to understand potential

solutions, technologies and sources

Conference findings, federally funded research and development center input, strategy papers, 4-year outlooks

2 Pre-Materiel Development Decision Engineering

ENGINEERING OF DEFENSE SYSTEMS GUIDEBOOK

5

Activities

During pre-MDD, ME and SE activities include the following:

Achieve an in-depth understanding of the current and evolving operational capability

gaps defined in the ICD or equivalent requirements documentation, and identifying the

sources of the gap(s), which, if addressed by a materiel solution, could achieve the

needed capability

Identify an appropriate range of candidate materiel solutions from across the trade space

to meet the need

Identify near-term opportunities to provide a more rapid interim response to the

capability need

Work with the S&T community (across Government, industry, and academia) as well as

other collaborators to build the technical knowledge base for each candidate materiel

solution in the AoA Guidance including experimentation and prototyping

Analyze trade space to determine performance versus cost benefits of potential solutions

Plan for the technical efforts required during the next phase

Perform an early evaluation of risks associated with the alternatives to be analyzed in the

next phase

Work with requirements developers to ensure the quality of all operational requirements

Outputs and Products

The pre-MDD effort ends after a successful MDD review in which the Milestone Decision

Authority approves entry into the DAS.

The MDD review requires an ICD, or equivalent, that represents an operational capability need

validated in accordance with CJCSI 5123. The Joint Staff provides this document, which is

generally the output of a Capability-Based Assessment, ME analysis, or other studies. The

designated Service representative should have access to both the ICD and supporting studies.

Other technical information (such as models, simulations, etc.) may be useful for understanding

both the need and its context. The S&T community can contribute pertinent data and information

on relevant technologies, prototypes, experiments, or analysis.

The MDD is documented in an Acquisition Decision Memorandum (ADM) signed by the

Milestone Decision Authority. The ADM specifies the approved entry point, typically the MSA

phase for the MCA pathway. Pre-MDD outputs (Table 2-2) also include approved AoA

Guidance and an AoA Study Plan, which should be informed by ME and SE activities.

2 Pre-Materiel Development Decision Engineering

ENGINEERING OF DEFENSE SYSTEMS GUIDEBOOK

6

2BTable 2-2. Technical Outputs Associated with Pre-MDD

Technical Outputs from Pre-MDD

Configuration-controlled Mission Baseline including validated mission definition(s) the program will maintain and

use to measure mission efficacy of the materiel solution and a basis for future acquisition decision touchpoints.

Configuration controlled operational Concept Baseline including validated reference mission threads and

recommended candidate materiel solution concepts for further analysis/refinement in the next acquisition phase.

Validated mission threads:

o Of the mission if executed with expected forces in the future time frame. These are titled the “As-Is” mission

thread(s) and should highlight or illustrate the potential gap or shortfall.

o Of alternative concept (regardless of materiel solution) mission approaches. These are titled the “To-Be”

mission thread concept(s).

o Suggested Mission Engineering Threads that preliminarily incorporate promising Doctrine, Organization,

Training, Materiel, Leadership and Education, Personnel, Facilities, and Policy (DOTMLPF-P) considerations

and materiel solution concepts.

Informed advice to the ICD, or equivalent

Informed advice to the AoA Guidance and Study Plan (See AoA Guidebook (forthcoming).)

Informed advice to the plan and budget for the next phase, including support to the AoA and non-AoA technical

efforts required to prepare for the initial milestone review

Informed advice to the ADM

All potential materiel solutions pass through an MDD before entering the DAS; however, the

Milestone Decision Authority may authorize entry at any point in the acquisition life cycle based

on the solution’s technical maturity and risk. If the Service-recommended entry point into the

MCA pathway is beyond the MSA phase, for example, partway through the Technology

Maturation and Risk Reduction (TMRR) phase, the program should document evidence that all

MSA and TMRR phase-specific entrance criteria and statutory requirements are met and that the

solution’s technical maturity supports entry at the point in the phase being proposed. Technical

risk has several elements: mission risk, technology risk, engineering risk, and integration risk.

The Service or designated representative should ensure the soundness of supporting technical

information and plans in order to inform the Milestone Decision Authority’s decision. The

technical plan and budget presented at the MDD should reflect the full range of activities

required in the next phase.

2.1 35BPre-MDD Mission Engineering Reviews

2.1.1 43BMission Review

DoD Joint Publication 3-0 (Joint Operations) defines a “mission” as the task, together with the

purpose, that clearly indicates the action to be taken and the reason thereby. The mission

definitions (validated by the Joint Staff and Combatant Commands) are the fundamental basis for

evaluating materiel solutions and trades. The Mission Review should ensure that the definition of

the future mission(s), either today or in the future, and the desired mission outcomes (measured

2 Pre-Materiel Development Decision Engineering

ENGINEERING OF DEFENSE SYSTEMS GUIDEBOOK

7

by mission metrics) have been adequately established and are sufficiently defined in order to

conduct Mission Engineering (see the ME Guide). In accordance with DoDI 5000.88, a

USD(R&E) representative will chair Mission Reviews for joint missions and the applicable Service

representative will chair Mission Reviews for Service-specific missions.

The Mission Review should establish and place under configuration control a validated and well-

articulated set of Mission Baselines. The Mission Baselines should include mission definitions

and time frames of interest in which the missions are set. Mission definitions include scenario

setting, threats, allies/partners, mission assumptions, mission objectives, constraints, mission

measures of success, and expected force laydown (i.e., position and qualities of platforms or

systems). These terms and the ME methodology are further described in the ME Guide.

There may be multiple (or a family of) Mission Baselines but with varying elements of the

mission definition – for example a change in the time frame of interest (i.e., 2025, 2030, 2035),

or multiple vignettes. The family of Mission Baselines should evolve to reflect the changing

threats, Defense Planning Guide, and National Defense Strategy. The baseline(s) should be

updated and revised at a minimum every 2 years to support the Future Years Defense Program

(FYDP) cycle and in sufficient time to guide ME activities in support of OUSD R&E investment

and DAS-based decisions. The Mission Review should trace the mission definition to the Joint

Capability Areas and provide scenario details to guide analyses of potential concept,

technological, DOTMLPF-P and materiel solutions.

Roles and Responsibilities

Under Secretary of Defense for Research and Engineering (USD(R&E))

o Provide guidance for defining components and details of Mission Baselines and

associated mission definitions

o Coordinate access to appropriate data repository(ies) and instructions

(upload/download, tagging, configuration control, etc.) to share Mission Review

products (i.e., Mission Baseline artifacts and other relevant data/material). Products

may include architectures, models, etc.

o Provide, along with Joint Staff, guidance and criteria for conduct of the Mission Review

o Chair, or co-chair with Joint Staff, Mission Reviews for joint missions

Joint Staff – for joint missions

o Host, or co-host with OUSD(R&E), Mission Reviews

o Provide validated mission definitions and baselines with support of combatant

commands (COCOMs)

o Include representatives of OUSD(R&E) and OUSD for Acquisition and Sustainment

(OUSD(A&S))

o Provide for sharing Mission Review products across the Department following

instructions and repository guidance from OUSD(R&E)

2 Pre-Materiel Development Decision Engineering

ENGINEERING OF DEFENSE SYSTEMS GUIDEBOOK

8

Services/Components – for Service-specific missions

o Host Mission Review

o Derive mission definitions from joint mission definitions and baselines

o Provide validated mission definitions and baselines with support of COCOMs

o As needed, include representatives of OUSD(R&E) and OUSD(A&S) in Mission

Reviews

o Provide for sharing Mission Review products across the Department

Inputs and Review Criteria

Mission definition(s)

o Time frame of intended mission(s) (year of conflict)

o Known strategic gaps in capability

o Traceability to Defense Planning Guide, Joint Capability Areas, Joint Task Lists, or

Service tasks lists

o Environmental conditions, geopolitical setup, expected threat, etc.

Assumptions and constraints that should be used for analyses

Mission measures of success

o Objectives of the mission in quantifiable terms

o Definitions of measures of effectiveness (MOEs) or other measures of performance

(MOPs) as well as key target values for these measures

Trades that are needed to inform mission refinement

Other interrelated Mission Baseline(s)

Outputs and Products

Documented Mission Baseline(s) that encompass the agreements and final products to

address the inputs and review criteria of the Mission Review

Traceability to Defense Planning Guide, Joint Capability Areas, and Joint Tasks Lists

o Documented capability gaps

Data or products needed to guide concept exploration and DOTMLPF-P evaluations to

support maturation of the Concept Design

o Questions requested by leadership to inform trades and support decisions

o Analyses needed to refine the mission definition(s)

All products should be made readily available to the Office of the Secretary of Defense

(OSD) and other DoD Components for use and integration across mission definitions

2 Pre-Materiel Development Decision Engineering

ENGINEERING OF DEFENSE SYSTEMS GUIDEBOOK

9

2.1.2 44BConcept Design Review

In accordance with DoDI 5000.88, a Concept Design Review (CoDR) will be conducted before

the MDD where the initial Concept Baseline(s) will be established. The CoDR will be chaired by a

USD(R&E) representative for joint missions and by the applicable Service representative for

Service-specific missions. The review is the culmination of concept exploration and DOTMLPF-

P evaluations to address preliminary solution trades to meet mission needs. The CoDR should be

a multidisciplined review of the potential joint warfare concepts, Service-specific concepts, and

DOTMLPF-P considerations to address the needs of the Mission Baseline. The review should

evaluate the rigor used to identify the candidate alternatives (both materiel and non-materiel) that

should be further explored to address the baseline missions. The Service representative informs

the CoDR by performing top-level ME analyses of future concepts and exploring integrated joint

force possibilities. These analyses should provide balanced and quantifiable insight to help

leadership rank order candidate concepts, non-materiel, and likely materiel (integrated joint,

service agnostic, as well as partner alliance) solutions. The CoDR products will inform the MDD

or provide guidance for non-materiel action by COCOMs.

The CoDR should establish the operational Concept Baseline and include recommended

candidate materiel alternatives and an update to the Mission Baseline materials (i.e., the mission

definition(s)). The Service representatives document the Concept Baseline to depict the mission

definition, the future time frame in which it is set, threats, scenario specifics, mission objectives,

constraints, mission measures of success, and expected force laydown (see the ME Guide). The

CoDR should also include a review of the supporting technology roadmaps and prototyping or

experimentation efforts (plans and results) that enable each of the concepts and alternatives. The

Service presents these candidates at the MDD to shape what the SE and ME team will further

evaluate as part of the AoA. The CoDR should include a technical sufficiency evaluation of the

AoA Study Guidance to ensure it is grounded to the Mission Baseline, it equally considers

Service-specific and joint alternatives, and it addresses the candidate “To-Be” mission thread(s)

resulting from the CoDR.

Roles and Responsibilities

USD(R&E)

o Provide guidance and details for establishing the Concept Baseline

o Provide guidance and criteria on the conduct of the CoDR

o For non-delegated studies, perform ME analyses to inform the Concept Baselines and

alternatives to support the CoDR and MDD

o Update and provide technology and prototyping or experimentation roadmaps

o Provide procedures, infrastructure, or a repository to share elements of Concept

Baselines, candidate alternatives, and decisions

2 Pre-Materiel Development Decision Engineering

ENGINEERING OF DEFENSE SYSTEMS GUIDEBOOK

10

USD(A&S)

o Provide DAS portfolio capability performance and schedules

Joint Staff – for joint missions

o Provide updated validated mission definitions and baselines with support of CCMDs

o Provide Joint Warfighting Concept roadmaps/architectures

o Provide for sharing ME and CoDR products across the Department

o Perform a Capability Portfolio Review as part of the CoDR if it was not conducted

separately

Services or Components

o Perform ME analyses to inform the Concept Baselines and alternatives to support the

CoDR and MDD

o Provide updated validated mission definitions and baselines with support of CCMDs

o As needed, include representatives of OUSD(R&E) and OUSD(A&S)

o Provide for sharing ME and CoDR products across the Department

Inputs and Review Criteria

Mission Baseline(s), including updated mission definitions informed by evolving mission

and threats

Technology, Prototyping and Experimentation roadmaps, and Joint Warfighting Concept

architectures

Program of Record (DAS portfolio) capability performance projections and schedules

ME analyses

Outputs and Products

Updated Mission Baseline(s)

Initial Concept Baseline(s), including:

o Identification of candidate concepts and alternatives that could meet the mission

objectives (initial rank ordering of the most promising solutions)

o Framing assumptions

o Concept Design Trade Matrix

o Concept of Operations (CONOPS), or Operational Mode Summary/Mission Profile

o Mapping to contributing technology and prototyping/experimentation roadmaps

o Program risk assessment (with technology development and other risk mitigation

activities, appropriate affordability targets, and initial schedule basis)

2 Pre-Materiel Development Decision Engineering

ENGINEERING OF DEFENSE SYSTEMS GUIDEBOOK

11

o Initial Security/Cybersecurity/Protection Assessment (identification of Critical

Technical Parameters, etc.)

o Validated reference mission threads

The mission, if executed, with expected forces in the future time frame. These are

titled the “As-Is” mission thread(s) and should highlight or illustrate the potential

gap/shortfall.

Alternative concept (material solution agnostic) mission approaches. These are

titled the “To-Be” mission thread concept(s).

Suggested Mission Engineering Threads that preliminarily incorporate promising

DOTMLPF-P considerations and material solution concepts for further

analysis/refinement in the next acquisition phase.

ME-informed Capability-Based Assessment

ICD

Informed DAS alternative pathway selection (quantitatively linking the mission

definition, time frame, gap and potential solution maturity level to the appropriate

acquisition model)

Updated AoA study guidance that incorporates USD(R&E) and ME-based direction

3 Engineering Guidance for the Acquisition Pathways

ENGINEERING OF DEFENSE SYSTEMS GUIDEBOOK

12

3 34BENGINEERING GUIDANCE FOR THE ACQUISITION PATHWAYS

3.1 36BOverview

Engineering provides the technical foundation for all DoD acquisition activities regardless of

Acquisition Category (ACAT) or acquisition pathway. In addition to the Acquisition Strategy,

PMs and systems engineers should develop an engineering approach that matches the acquisition

pathway processes, reviews, documents, and metrics to the character and risk of the capability

being acquired. Although this guidance document employs some terminology mainly applicable

to the MCA pathway, the principles and practices should be applied, as appropriate and tailored,

to all DoD system development. While an MDAP or major system using the MCA pathway will

typically employ the majority of activities and events described in this document, it is prudent for

the PM and Systems Engineer to consider all of these activities and events for their respective

program regardless of pathway.

3.2 37BMajor Capability Acquisition

Major Capability Acquisitions (MCAs) follow a process designed to support MDAPs, major

systems, and other complex acquisitions. The MCA approach includes steps to analyze, design,

develop, integrate, test, evaluate, produce, and support. Programs tailor acquisition and product

support processes, reviews, and documentation (including digital artifacts and models as

representations of reality) depending on the program size, complexity, risk, urgency, and other

factors. Programs may acquire software-intensive components via the Software Acquisition

pathway and integrate the products and align dependencies into the MCA program.

3.2.1 45BSystems Engineering

3.2.1.1 Life Cycle Expectations

The SE described in this document spans the acquisition life cycle and is based on DoDD

5000.01, DoDI 5000.02; DoDI 5000.85, Major Capability Acquisition; and DoDI 5000.88.

Programs should tailor the SE content to fit the technology maturity, risks, interdependencies,

related characteristics, and context for the program or the system of interest. The following

sections identify the SE activities, processes, inputs, outputs, and expectations during each

acquisition phase and for each technical review and audit.

Acquisition milestones and SE technical reviews and audits serve as key points throughout the

life cycle to evaluate significant achievements and assess technical maturity and risk. Table 3-1

identifies the objectives of each SE assessment and the technical maturity point marked by each

review. The MDD review is the entry point into the MCA process and is mandatory for all

programs in accordance with DoDI 5000.85, Section 3.5.a. Depending on the maturity of the

preferred materiel solution, at the MDD review the Milestone Decision Authority officially

designates the MSA phase as the entry point or may designate the entry point as Milestone B, or

C as appropriate. The Milestone Decision Authority documents the decision in a signed ADM

3 Engineering Guidance for the Acquisition Pathways

ENGINEERING OF DEFENSE SYSTEMS GUIDEBOOK

13

published immediately after the MDD event. Since the review milestone must be consistent with

the maturity of the preferred materiel solution, entry at any milestone requires evidence of the

associated solution maturity, as summarized in Table 3-1.

Department experience (e.g., GAO Report 12-400SP) demonstrates that successful programs use

knowledge-based product development practices that include steps and techniques to gather and

curate knowledge to confirm the program’s technologies are mature, their designs are stable, and

their production processes are in control. Successful materiel developers ensure programs

acquire a high level of knowledge about a system at key junctures in development. Table 3-1

summarizes the concept of technical maturity points.

3BTable 3-1. Technical Maturity Points

Technical Maturity Points

DoD Acquisition

Milestone/Decision

Point and Technical

Review/Audit

Objective

Technical Maturity Point

Additional Information

Materiel Development

Decision (MDD)

Decision to assess

potential materiel

solutions and

appropriate phase for

entry into acquisition

life cycle.

Capability gap met by

acquiring a materiel

solution.

Technically feasible solutions

have the potential to effectively

address a validated capability

need. Technical risks understood.

Alternative Systems

Review (ASR)

Recommendation

that the preferred

materiel solution can

affordably meet user

needs with

acceptable risk.

System parameters

defined; balanced with

cost, schedule and risk.

Initial system performance

established and plan for further

analyses (e.g., assessing

technical maturity and associated

risks) supports Milestone A

criteria.

Milestone A

Decision to invest in

technology

maturation and

preliminary design.

Affordable solution found

for identified need with

acceptable technology risk,

scope, and complexity. 10

USC 2366a certification, if

applicable.

Affordability goals identified and

technology development plans,

time, funding, and other resources

match customer needs.

Prototyping and end-item

development strategy for TMRR

phase focused on key technical

risk areas.

System Requirements

Review (SRR)

Recommendation to

proceed into

development with

acceptable risk.

Level of understanding of

top-level system/

performance requirements

is adequate to support

further requirements

analysis and design

activities.

Government and contractor

mutually understand system

/performance requirements

including:

(1) the preferred materiel solution

(including its support concept)

from the MSA phase;

(2) plan for technology and

manufacturing maturation; and

(3) maturity of interdependent

systems.

3 Engineering Guidance for the Acquisition Pathways

ENGINEERING OF DEFENSE SYSTEMS GUIDEBOOK

14

Technical Maturity Points

DoD Acquisition

Milestone/Decision

Point and Technical

Review/Audit

Objective

Technical Maturity Point

Additional Information

System Functional

Review (SFR)

Recommendation

that functional

baseline satisfies

performance

requirements and to

begin preliminary

design with

acceptable risk.

Functional baseline

established and under

formal configuration

control. System functions

in the system performance

specification decomposed

and defined in

specifications for lower

level elements, that is,

system segments and

major subsystems.

Functional requirements and

verification methods support

achievement of performance

requirements. Acceptable

technical risk of achieving

allocated baseline. See SE

Guidebook Section 4.1.6,

Configuration Management

Process for a description of

baselines.

Capability

Development

Document (CDD)

Validation

Requirements

validation authority

action. Provides a

basis for preliminary

design activities and

the preliminary

design review (PDR).

Major cost and

performance trades have

been completed and

enough risk reduction has

been completed to support

a decision to commit to the

set of requirements (i.e.,

CDD or equivalent)

Support preparation for CDD

validation by performing systems

engineering trade-off analysis with

Modular Open Systems Approach

(MOSA) considerations

addressing relationships of cost,

requirements, design, and

schedule. Once validated, a

Configuration Steering Board

assumes responsibility to review

all requirements changes and any

significant technical configuration

changes for ACAT I and IA

programs in development,

production, and sustainment that

have the potential to result in cost

and schedule impacts to the

program.

Preliminary Design

Review (PDR)

Recommendation

that allocated

baseline satisfies

user requirements

and developer ready

to begin detailed

design with

acceptable risk.

Allocated baseline

established such that

design provides sufficient

confidence to proceed with

detailed design. Baseline

also supports 10 USC

2366b certification, if

applicable.

Preliminary design and

appropriate architecture products

support capability need and

affordability goals and/or caps

achievement. For MDAPs,

Secretary of Defense (SecDef)

approved program cost, fielding,

and performance goals are

achievable. See SE Guidebook

Section 4.1.6. Configuration

Management Process for a

description of baselines.

3 Engineering Guidance for the Acquisition Pathways

ENGINEERING OF DEFENSE SYSTEMS GUIDEBOOK

15

Technical Maturity Points

DoD Acquisition

Milestone/Decision

Point and Technical

Review/Audit

Objective

Technical Maturity Point

Additional Information

Development Request

for Proposal (RFP)

Release Decision

Point

Determination that

program plans are

affordable and

executable and that

the program is ready

to release RFPs for

Engineering and

Manufacturing

Development (EMD)

and/or for Low-Rate

Initial Production

(LRIP).

Systems engineering

trades completed and have

informed program

requirements. Competitive

and risk reduction

prototyping and the

development of the

preliminary design have

influenced risk

management plans and

should-cost initiatives.

The RFP reflects the program’s

plans articulated in the draft (as

defined in DoDI 5000.88, Section

3.9) Acquisition Strategy and

other draft, key planning

documents such as the Systems

Engineering Plan (SEP), Program

Protection Plan (PPP), Test and

Evaluation Master Plan (TEMP),

and Life Cycle Sustainment Plan

(LCSP). The RFP also includes a

MOSA Strategy that clearly

describes the modular open

system approach to be used for

the program (as described in

DoDI 5000.88, Section 3.7)

Milestone B

Decision to invest in

product development,

integration, and

verification as well as

manufacturing

process

development;

decision on LRIP

quantity.

Critical technologies

assessed able to meet

required performance and

are ready for further

development. Resources

and requirements match.

Maturity, integration, and

producibility of the preliminary

design (including critical

technologies) and availability of

key resources (time, funding,

other) match customer needs.

Should-cost goals defined. Clearly

define modular system interfaces

between the major system

platform and major system

components and between major

system components and modular

platforms. Ensure that the MOSA

Strategy ensures there are

standardized interfaces and

appropriate arrangements for

obtaining necessary IP rights

have been addressed and

implemented (as described in

DoDI 5000.88, Section 3.7).

Critical Design

Review (CDR)

Recommendation to

start fabricating,

integrating, and

testing test articles

with acceptable risk.

Product design is stable.

Initial product baseline

established.

Product baseline is initially

established by the system

detailed design documentation;

affordability/should-cost goals

confirmed. Government assumes

control of initial product baseline

as appropriate. See SE

Guidebook Section 4.1.6.

Configuration Management

Process for a description of

baselines.

3 Engineering Guidance for the Acquisition Pathways

ENGINEERING OF DEFENSE SYSTEMS GUIDEBOOK

16

Technical Maturity Points

DoD Acquisition

Milestone/Decision

Point and Technical

Review/Audit

Objective

Technical Maturity Point

Additional Information

System Verification

Review

(SVR)/Functional

Configuration Audit

(FCA)

Recommendation

that the system as

tested has been

verified (i.e., product

baseline is compliant

with the functional

baseline) and is

ready for validation

(operational

assessment) with

acceptable risk.

System design verified to

conform to functional

baseline.

Actual system (which represents

the production configuration) has

been verified through required

analysis, demonstration,

examination, and/or testing.

Synonymous with system-level

FCA. See SE Guidebook Section

4.1.6. Configuration Management

Process for a description of

baselines.

Production

Readiness Review

(PRR)

Recommendation

that production

processes are mature

enough to begin

limited production

with acceptable risk.

Design and manufacturing

are ready to begin

production.

Production engineering problems

resolved and ready to enter

production phase.

Milestone C and

Limited Deployment

Decision

Decision to produce

production-

representative units

for operational test

and evaluation

(OT&E) and/or

decision that

increment of

capability is ready for

Limited Deployment.

Manufacturing processes

are mature enough to

support LRIP (and/or

Limited Deployment) and

generate production-

representative articles for

OT&E. Increment of

capability has stable

design.

Production readiness meets cost,

schedule, and quality targets.

Begin initial deployment and/or

deploy increment of capability.

Physical

Configuration Audit

(PCA)

Recommendation to

start full-rate

production and/or full

deployment with

acceptable risk.

Product baseline

established. Verifies the

design and manufacturing

documentation, following

update of the product

baseline to account for

resolved OT&E issues,

matches the physical

configuration.

Confirmation that the system to be

deployed matches the product

baseline. Product configuration

finalized and system meets user’s

needs. Conducted after OT&E

issues are resolved. See SE

Guidebook Section 4.1.6.

Configuration Management

Process for a description of

baselines.

Full-Rate Production

Decision Review (FRP

DR) or Full

Deployment Decision

Review (FDDR)

Decision to begin full-

rate production

and/or decision to

begin full

deployment.

Manufacturing processes

are mature and support

full-rate production and/or

capability demonstrated in

operational environment

supporting full deployment

(i.e., system validated

through OT&E).

Delivers fully funded quantity of

systems and supporting materiel

and services for the program or

increment to the users.

3 Engineering Guidance for the Acquisition Pathways

ENGINEERING OF DEFENSE SYSTEMS GUIDEBOOK

17

Figure 3-1 provides the end-to-end perspective and the integration of SE technical reviews and

audits across the system life cycle.

4BFigure 3-1. Major Capability Acquisition Life Cycle

The Systems Engineer supports the PM in developing and implementing a technical program

strategy. SE processes within this technical program strategy help deliver capabilities that meet

warfighter needs within cost and schedule by balancing end-user needs, design considerations,

resource constraints, and risk. The Systems Engineer uses technical reviews and audits to assess

whether the program reaches preplanned technical maturity points during the acquisition life

cycle as the system and system elements mature. The Systems Engineer facilitates the program’s

ability to achieve the entry criteria for these points by identifying and mitigating technical risks

leading up to reviews and audits (see the DoD Risk, Issue, and Opportunity Management Guide

for Defense Acquisition Programs.)

The Systems Engineer should strive to ensure consistency among analyses that support key

decision and transition points throughout a program’s life cycle. For instance, models,

simulations, tools, and data should be integrated into the SE activities and reused to the greatest

extent possible (see SE Guidebook Section 2.2.1. Models and Simulations and Section 2.2.2

Digital Engineering). This knowledge forms part of the authoritative source of truth for the

system, as well as the basis for the Systems Engineer’s recommendations to the PM regarding

how to technically proceed with the program.

3 Engineering Guidance for the Acquisition Pathways

ENGINEERING OF DEFENSE SYSTEMS GUIDEBOOK

18

3.2.1.2 Systems of Systems and Mission Engineering

Whether or not a system is acknowledged as a system of systems (SoS), nearly all DoD systems

function as part of an SoS to deliver a necessary capability to the user. SoS engineering is an

ongoing, iterative process, as shown in the SoS SE Implementers’ View in Figure 3-2. The

backbone of SoS SE implementation is a continuous ME analysis that considers changes from

the broader operational mission environment as well as feedback from the ongoing engineering

process.

As previously mentioned, ME is an iterative analysis and multidisciplinary activity to analyze,

organize, and integrate current and emerging operational and system capabilities to achieve

desired warfighting mission effects. Implementing a digital engineering technical approach at the

beginning of a program’s life cycle may greatly facilitate this iterative ME approach.

ME provides the quantitative basis for developing and evolving SoS architectures, evaluating

contributions of constituent systems within the SoS, and guiding changes to achieve mission

success. Ensuring a robust ME approach provides structure to the maturation of systems within

the SoS, which are typically on different life cycle timelines, and helps ensure systems and

Concept of Operations, Operational Mode Summaries, and Mission Profiles

(CONOPS/OMS/MP) adapt and integrate to meet the evolution of the mission.

5BFigure 3-2. SoS SE Implementers’ View

ME should address the end-to-end behavior of the ensemble of systems, addressing the key

issues that affect this end-to-end behavior with particular emphasis on integration and

interoperability. ME planning and implementation should consider and leverage the development

plans of the individual systems in order to balance SoS needs with individual system needs. ME

analyses help provide an input in the development of an architecture and balance the technical

management of the SoS. ME provides a basis for digital engineering, modeling and simulation,

and MOSA to rapidly adapt as adversaries change. Refer to the SE Guidebook, Section 3, for

additional information on SoS.

3 Engineering Guidance for the Acquisition Pathways

ENGINEERING OF DEFENSE SYSTEMS GUIDEBOOK

19

Consideration of SoS in SE for Individual Systems

Most acquisition programs address the development or major upgrade of individual systems (in

contrast to SoS). Understanding the SoS context(s) of the system (including use in multiple

operational environments) is critical to developing requirements for the system so, when

delivered, the system operates effectively in user operational environments. From the JCIDS

Capability-Based Assessment through sustainment activities, it is important to recognize how the

system context influences system requirements. An up-to-date CONOPS/OMS/MP for the

system is essential to understanding the system context, notably, mission and task threads and

data exchanges that have an impact on the system. Systems Engineers of individual systems

should collaborate to ensure the program addresses SoS considerations and risks throughout the

acquisition life cycle:

Identify system dependencies and interoperability needs (see SE Guidebook, Section

5.12. Interoperability and Dependencies) through ME analysis.

Factor these dependencies into the development of system concepts, requirements, and

risks.

Address these dependencies through trade analysis, system architecture and design,

interface development and management, and verification and validation.

Clearly define modular system interfaces between major system platform and major

system components, between major system components, and between major system

platforms (see DoDI 5000.88 Section 3.7).

From an individual system perspective and from the SoS perspective, PMs and Systems

Engineers may find it difficult to balance the acquisition objectives and strategies for a given

system with those of other systems.

DoD engineers have determined the following as best practice:

Closely monitor interdependent programs, with checkpoints at scheduled design reviews

to assess program progress, assess related risks and determine actions to mitigate

potentially negative impacts.

Allow technical representatives from each system participate in one another’s System

Functional Review (SFR), Preliminary Design Review (PDR), and Critical Design

Review (CDR).

Establish a senior governance body to provide a forum for discussion and decision. This

forum should address functional capabilities, technical plans, configuration management

and strategies with respect to interfaces, interdependences, risks, and risk mitigation. It is

critical that the program address all equities and make collective decisions that can be

implemented as changes to a system’s configuration.

3 Engineering Guidance for the Acquisition Pathways

ENGINEERING OF DEFENSE SYSTEMS GUIDEBOOK

20

In all cases the programs should support an ME methodology (as described in the ME Guide) to

fully examine the relationships and contributions of the system and SoS relative to a mission

context and in a selected mission thread(s).

Table 3-2 lists ME and SoS considerations for systems at each stage of acquisition. At each

phase, the SE approach to addressing SoS-related dependencies should be addressed in the SEP.

6BTable 3-2. Key ME and SoS Considerations for Systems by Acquisition Phase

Acquisition Phase

Considerations

Pre-Materiel

Development

Decision (Pre-MDD)

Role of the system in supporting a mission capability, including relationship to other

systems in the SoS that support that capability

Mission Architecture with various scenarios (e.g., mission thread) of capability gap in

context of specified mission

Mission threads that describe the flow of tasks/activities in relationship to other

systems and context

Identification of relevant Joint DOTMLPF-P

Identification of stakeholders

Provided by the ME analysis and the evidence provided at MDD

Materiel Solution

Analysis (MSA)

In the AoA, consider the alternatives in the context of the larger SoS supporting the

capability; use ME processes as part of the AoA

Include a SoS context for the ME analysis that includes the preferred materiel

solution: evaluate dependencies and relationships with other systems, modular

system interfaces, modular systems, and technical risks based on SoS considerations

to be addressed in TMRR

Identify non-materiel changes needed to implement a specific materiel solution, e.g.

changes to tools, techniques and procedures to enable the SoS capability

AoA criteria or results relevant to SoS dependencies or modular system interfaces

Identify and define system dependencies and modular system interfaces that

influence system requirements

Initial management plans with supporting memoranda of agreements (MOAs),

including draft Interface Control Agreements for collaborations with other systems in a

SoS

System Safety Engineering Activities (e.g. Physical Hazard Analysis (PHL), System

Safety Management Plan, etc.) to assess materiel solutions by identifying inherent

hazard risks and develop criteria to define key objectives for the SS Program

Risks associated with SoS dependencies (both programmatic and technical) and

interoperability requirements, including System Safety, environment, occupational

health, and security risks to be accepted by Joint Authorities

Modeling and simulation tools to support trade space analysis and manufacturing

feasibility evaluations

SoS-related requirements in draft system performance specification or pre-MS A RFP

MOAs with key parties in SoS dependencies or relationships

3 Engineering Guidance for the Acquisition Pathways

ENGINEERING OF DEFENSE SYSTEMS GUIDEBOOK

21

Acquisition Phase

Considerations

Technology

Maturation and Risk

Reduction (TMRR)

Assess the technical approaches and risks for addressing system requirements

including considerations for the system as a component operating in a SoS context

(including dependencies, interoperability and modular interfaces)

Address considerations of changes needed in other systems for the systems in

acquisition to meet capability objectives

An interface management plan, including MOAs and a schedule, that is a part of a

configuration management plan, including Interface Control Agreements

Risks associated with SoS dependencies (both programmatic and technical) and

interoperability requirements, including System Safety, environment, and

occupational health, and security risks to be accepted by Joint Authorities

Models and simulation tools used to support early assessment of requirement trade

space, performance specifications, operational suitability and affordability, and

manufacturing processes

Initiation of a digital engineering ecosystem with digital artifacts to support the

system’s life cycle and program decision making

Output of studies which validate the technical fit and operational suitability of the

system under development within the SoS

Final interface specifications

Progress with respect to schedule and plan milestones

Progress with respect to expected performance

Engineering and

Manufacturing

Development (EMD)

Develop, verify, and validate the detailed design that addresses system requirements,

considering the SoS context including recognized dependencies and modular system

interfaces

Interface documentation, digital artifacts, test plans and test reports

Update to MOAs with system’s dependencies

Risks associated with SoS dependencies (both programmatic and technical) and

interoperability requirements, including System Safety, environment, and

occupational health, and security risks to be accepted by Joint Authorities

Digital engineering ecosystem and implementation plan (models, simulations, etc.) to

support concurrent and collaborative engineering, reduce defects and rework costs,

accelerate the development schedule, improve system design, and software reliability

and quality

Successful development and test of interfaces

Verification and compliance of modular system interfaces with widely supported and

consensus-based standards (if available and suitable)

Progress with respect to SoS schedule and plan milestones

Progress with respect to expected performance

Production and

Deployment (P&D)

and Operations and

Support (O&S)

Verify the as-built system and interdependent systems’ interfaces meet standards and

specifications and support operational needs

Support effective system operation in a SoS context

Test reports

Digital artifacts (models, simulations, etc.) reflect the production configuration to

rapidly evaluate changing threats, explore solution space, and support design reuse

Mature digital engineering ecosystem to support future system enhancements and

upgrades, sustainment activities, decision making, and assessments such as mission

engineering

3 Engineering Guidance for the Acquisition Pathways

ENGINEERING OF DEFENSE SYSTEMS GUIDEBOOK

22

3.2.1.3 Systems Engineering Activities in Life Cycle Phases

This section describes the objectives and technical activities typically performed in each of the

five life cycle phases of the MCA pathway (MSA, TMRR, EMD, P&D, and Operations and

Support (O&S)). For each phase, the description includes the roles and responsibilities of a

Systems Engineer in the program office, inputs normally required to constrain the technical

activities, activities the Systems Engineer performs, and outputs and products of the phase.

Although this section mentions technical reviews and audits, more details are covered in the SE

Guidebook Section 3, Technical Reviews and Audits.

3.2.1.3.1 Materiel Solution Analysis Phase

The objective of the MSA phase is to select and adequately describe a preferred materiel solution

to satisfy the phase-specific entrance criteria for the next program milestone designated by the

Milestone Decision Authority. Before completing the MSA Phase, the Component Acquisition

Executive (CAE) selects a PM and establishes a program office to complete the necessary

actions associated with planning the acquisition program. Usually, but not always, the next

milestone is a decision to invest in technology maturation, risk reduction activities, and

preliminary design in the TMRR phase. During the MSA phase the SE team develops several

products including the following:

A system model or architecture that captures operational context and envisioned

concepts, describes the system boundaries and interfaces, and addresses operational and

functional requirements

Foundation of the program’s digital engineering ecosystem

Preliminary system performance specification that defines the performance of the

preferred materiel solution

Advice to the PM regarding what components of the system should be prototyped, why,

and how

The MSA phase has two major blocks of activity: (1) the AoA led by the Director, Cost Analysis

and Program Evaluation and conducted by a designated DoD Component and (2) the post-AoA

operational analysis and concept engineering to prepare for a next program milestone designated

by the Milestone Decision Authority (Figure 3-3).

3 Engineering Guidance for the Acquisition Pathways

ENGINEERING OF DEFENSE SYSTEMS GUIDEBOOK

23

7BFigure 3-3. Activities in Materiel Solution Analysis Phase

During the MSA phase, the program team identifies a materiel solution to address current and

evolving user capability gaps partially based on the AoA. Once the Service sponsor selects a

preferred materiel solution, the program team prepares for the next life cycle phase by focusing

engineering and technical analysis on this solution to ensure the development plans, schedule,

funding, and other resources match customer needs and the complexity of the preferred materiel

solution. The program should integrate SE activities with MSA phase-specific test, evaluation,

logistics, and sustainment activities identified in the T&E Enterprise Guidebook (forthcoming).

and Sustainment Guidebook (forthcoming).

The AoA team considers a range of alternatives and evaluates them from multiple perspectives

as directed by the AoA Guidance and AoA Study Plan. The guidance and plan should address

engineering considerations including technical risk. For MDAPs, the guidance and plan also

should include considerations of evolutionary acquisition, digital engineering, prototyping, and

MOSA, pursuant to 10 USC 2446b.(b).

The objective of the AoA is to analyze and characterize each alternative (or alternative approach)

relative to the others. The AoA does not result in a recommendation for a preferred alternative; it

provides information that the Service sponsor uses to select which materiel solution to pursue.

The Systems Engineer should participate in the AoA to conduct ME activities as indicated in the

ME Guide, including analyzing the impact of performance, technology, and manufacturing

feasibility on mission efficacy.

3 Engineering Guidance for the Acquisition Pathways

ENGINEERING OF DEFENSE SYSTEMS GUIDEBOOK

24

Using the AoA results, the Service sponsor may conduct additional engineering analysis to

support the selection of a preferred materiel solution. As the Milestone Decision Authority

selects preferred solutions, the Service sponsor will further mature them in preparation for the

next program milestone. After the AoA, Systems Engineers establish the technical performance

requirements consistent with the draft CDD, required at the next program milestone designated

by the Milestone Decision Authority. These requirements form the basis for the system

performance specification placed on contract for the TMRR phase; they also inform plans to

mitigate risk in the TMRR phase.

In the MSA phase, the DoD Component combat developer (e.g., Requirements Manager)

prepares a CONOPS/OMS/MP, consistent with the validated/approved capability requirements

document, typically an ICD. The CONOPS/OMS/MP includes the operational tasks, events,

durations, frequency, operating conditions and environment in which the recommended materiel

solution is to perform each mission and each phase of a mission. The CONOPS/OMS/MP

informs the MSA phase activities and the development of plans for the next phase.

During MSA, the program addresses several planning elements to frame the way forward for the

Milestone Decision Authority’s decision at the next program milestone. SE is a primary source

for addressing several of these planning elements (see SE Guidebook Section 4.1.1. Technical

Planning Process):

Capability need, architecture

System concept, architecture

Modular system interfaces

Acquisition approach

Engineering/technical approach

Program Protection approach

Manufacturing and Quality (M&Q) approach

Test and evaluation (T&E) approach

Program management approach

External dependencies/agreements

Schedule

Resources

Risks

The program documents the plans in the Acquisition Strategy, TEMP, PPP, next-phase RFP, and

the SEP. The SEP describes the SE efforts necessary to provide informed advice to these other

planning artifacts (see the SEP Outline).

3 Engineering Guidance for the Acquisition Pathways

ENGINEERING OF DEFENSE SYSTEMS GUIDEBOOK

25

SE provides, for example, the technical basis for TMRR phase planning and execution, including

identification of critical technologies, development of a competitive and risk reduction

prototyping strategy to include physical and digital prototyping considerations, and