i

Statement of Work (SOW) Template

for

Remedial Investigation and Feasibility Study (RI/FS)

at a

Munitions Response Site (MRS)

1

FOR OFFICIAL DON USE ONLY [INSERT DATE]

Department of the Navy

NAVFAC [fill in the appropriate FEC]

Statement of Work (SOW)

Contract Number:

The statement of work shall be as outlined below and as described elsewhere in the basic

contract number [insert].

REMEDIAL INVESTIGATION AND FEASIBILITY STUDY

MUNITIONS RESPONSE PROGRAM (MRP)

[Insert Installation/Site Name]

RPM Note: Please refer to the Remedial Project Manager (RPM) Notes provided

throughout this template and delete all notes prior to finalizing the SOW. As used in this

document, the term Munitions and Explosives of Concern (MEC) includes Discarded

Military Munitions (DMM), Unexploded Ordnance (UXO), and Munitions Constituents (MC)

(e.g., TNT, RDX) in high enough concentrations to pose an explosive hazard. Munitions

Constituents (MC) are defined as materials originating from UXO, DMM or other military

munitions, including explosive and non-explosive materials, and emission, degradation

or breakdown elements of such ordnance or munitions. Include the specific definitions

from the introduction if needed. The CECOS Munitions Response Site Management

course maintains a list of definitions that are relevant to the Munitions Response

Program. Obtain the latest course CD from a coworker or CECOS if additional definitions

are needed.

Text highlighted in yellow indicates where you need to provide information specific to

your project.

You will want to consider if you need a separate SOW for the planning phase prior to

scoping and awarding a contract for the field work. It is important to ensure that your

stakeholders are in agreement with the planned approach.

Reference information is available at the Munitions Response Workgroup web portal at

https://portal.navfac.navy.mil/portal/page/portal/NAVFAC/NAVFAC_WW_PP/NAVFAC_

NFESC_PP/ENVIRONMENTAL/ERB/MRP

As a reminder, the RPM must update the Munitions Response Site Prioritization Protocol

(MRSPP) priority in NORM if any of the following circumstances are met:

2

• Upon completion of a response action that changes the conditions of a

Munitions Response Site (MRS) in a manner that could affect the evaluation under

this Protocol;

• To update or validate a previous evaluation of an MRS when new information is

available;

• To update or validate the priority assigned (to an MRS) where that priority has

been previously assigned based on evaluation of only one or two of the three

hazard evaluation modules;

• Upon further delineation and characterization of an Munitions Response Area

(MRA) into more than a single MRS; or

• To categorize any MRS previously classified as “evaluation pending.”

The Protocol is only required to be reapplied once sufficient new data are available. If no

new data are available at the time of annual review, the Protocol need not be reapplied.

See the Munitions Response Site Prioritization Primer for more details.

1.0 OBJECTIVE

The objective for this task order is to perform a Remedial Investigation (RI) [and Feasibility

Study] (FS) to address the past use of Munitions and Explosives of Concern (MEC) and

Munitions Constituents (MC) for a Munitions Response Site(s) (MRS) [insert the site specific

identifier] at [insert installation, City, State].

The purpose of this Remedial Investigation and Feasibility Study (RI/FS) is to determine the

nature and extent of the hazard/threat presented by MEC/MC contamination at [Insert Site] and,

if sufficient need is documented by site sampling, perform an explosives safety hazard

assessment, and a MC risk assessment, and evaluate proposed MEC/MC remedies. Integrating

the development of the RI and FS is important to ensure that data obtained in the RI is

appropriate to evaluate likely remedial alternatives during the FS. The contractor shall

determine the nature and extent of the release of MEC/MC at the site, provide data for the

explosive safety hazard assessment/MC risk assessment, perform the hazard/risk assessment,

and collect sufficient data to develop and evaluate potential remedial alternatives as necessary

and to recommend a preferred alternative for those areas of concern (AOC) within the MRS that

have been determined to present an unacceptable explosive safety hazard or risk.

This action will be performed in accordance with the Comprehensive Environmental Response,

Compensation and Liability Act (CERCLA), Sections 104 and 121; Executive Order 12580; and

the National Oil and Hazardous Substances Pollution Contingency Plan (NCP). [RPM to identify

other regulatory drivers for this project.]

2.0 SCOPE

The scope of this Task Order is to conduct all work required to complete the final RI/FS Report

for the site with Navy and regulatory concurrence. Details of this scope are further defined in

Section 4. All work must be performed following applicable and appropriate Department of

Defense (DOD) guidance and policy for Munitions Response Program (MRP) response actions

and consider all site documentation and reports to date. The RI for this site shall consist of field

investigations, including [geophysical surveys, intrusive investigation, MC sampling, etc] to

characterize the nature and extent of MEC and MC (e.g., compound, affected medium, level of

3

contamination, extent of area affected, etc.) sufficient to assess the extent to which the MEC

and MC poses an explosive safety hazard or risk to human health and the environment and to

support the analysis and design of potential response actions

if the site poses an unacceptable

explosive hazard or health risk. The RI will provide a basis for decisions on further response

actions or no further action (NFA). An MEC explosives safety hazard assessment (MEC HA)

shall be conducted as part of the RI. Guidance in conducting the MEC HA can be found in the

Munitions And Explosives Of Concern Hazard Assessment Methodology (EPA/DoD/DoI,

February 2010).

RPM Note: To address explosive safety hazards from MEC, which includes MC at a high

enough concentration to pose an explosive hazard, the DoD, EPA, Department of Interior

(DOI), and state and tribal organizations developed the MEC Hazard Assessments (MEC

HA) Methodology (most current revision, Feb 2010, is noted above). It qualitatively

addresses human health and safety concerns associated with potential exposure to MEC

and serves two main purposes:

1)

To suppor

t the hazard management decision-making process by analyzing site-

specific information to evaluate removal and remedial alternatives, and to assess l

and

use activity decisions; and

2) To support the communication of hazards between members of the project team and

among other stakeholders, and by organizing site information in a consistent manner.

In the Spring of 2009 OSD, Department of the Army, and DON agreed to the use of the

MEC HA Methodology under a two-year trial period. The CNO letter of 6 Apr 09 states

that for each RI/FS, the RPM shall evaluate this tool and decide, along with their

regulatory and stakeholder partners, whether the MEC HA methodology is appropriate

for the specific site. Furthermore, where the team decides to implement this tool, further

evaluation shall be required regarding the outcome and effectiveness from

implementation of this tool. Contact your FEC MR workgroup member for the MEC HA

evaluation form to use in this evaluation.

Along with the MEC HA guidance document, RPMs may find it useful to review MEC HAs

that have already been developed for other MRSs.

The risk assessment from exposure to MCs below a concentration to pose an explosive

hazard should follow the Navy’s tiered approach for both the Human Health Risk

Assessment and the Ecological Risk Assessment. The relevant Navy Policies are:

“Conducting Human Health Risk Assessments Under the Environmental Restoration

Program” (Ser N453E/10595168, 12 Feb. 2001); and “Navy Policy for Conducting

Ecological Risk Assessments” (Ser N453E/9U595355, 05 Apr. 1999). Navy guidance for

conducting a human health risk assessment is provided in “U.S. Navy Human Health

Risk Assessment Guidance”, December 2008. Navy guidance for conducting an

ecological risk assessment is provided online at

http://www.nmcphc.med.navy.mil/downloads/ep/Risk%20Assessment/Chapters%201-12.

pdf . If

the RI/FS is only intended to address the explosive hazard, remove the MC risk

assessment language from this SOW.

The RI shall use the existing site information to accomplish the following:

• D

evelop a Work Plan for collecting necessary field data and other project plans

4

o Establish Data Quality Objectives (DQOs) for your site in coordination with

stakeholders (see U.S.E.P.A. Guidance on Systematic Planning Using the DQO

Process (EPA QA/G-4, 2006)

o Based on established DQOs for the project, select the appropriate detection

technology and anomaly investigation approach for MEC/MC (e.g. Digital

Geophysical Mapping (DGM), Mag & Flag.)

o Identify the appropriate MEC investigation design and depth based on the

current, determined, or reasonably anticipated future land use (e.g. USACOE 11x

rule)

o Develop an Explosives Safety Submission (ESS) for Naval Ordnance Safety and

Security Activity (NOSSA) or Marine Corps Systems Command

(MARCORSYSCOM) endorsement and Department of Defense Explosives

Safety Board (DDESB) approval

RPM Note: A general rule of thumb developed by the USACOE for MEC detectors is that

they can detect MEC at depths <11 times the MEC item’s diameter. Figure 1 at the end of

this SOW template helps illustrate this point. RPMs can use this information to get a

rough idea of the depth of detection for the MEC investigation. The geophysical system

verification instrument test strip and blind seeds will identify the actual site performance

that is achievable. The RPM note for section 3.5.2 discusses the geophysical system

verification in more detail.

The RI contractor shall then:

• Conduct the field work and assess the data collected to characterize the site

o Perform an explosives safety hazard assessment and a MC risk assessment

considering MEC/MC findings, access, land uses, and regulatory input which will

provide a basis for decisions on further response actions or no further action

(NFA)

o Update the Conceptual Site Model (CSM) based on the site information

and form

the basis for the development of Remedial Action (RA) Objectives

The overall objective of the FS is to develop and evaluate potential remedies that permanently

and significantly reduce the hazard/threat to public health, welfare, and the environment using

the nine criteria established by CERCLA for remedy selection

[40 CFR 300.430(e)(9)(iii)]

. These

criteria are:

- P

rotection of Human Health and the Environment

- Compliance with Applicable or Relevant and Appropriate Requirements (ARARs)

- Long Term Effectiveness and Permanence

- Reduction of Toxicity

- Short Term Effectiveness

- Implementability

- Cost

- State Acceptance

- Community Acceptance

The FS shall use the data generated from the RI, with input from the MEC HA and MC risk

assessments, to accomplish the following:

• Develop and Screen Remediation Alternatives for Effectiveness, Implementability

and Cost

5

o Identify the appropriate remedy alternatives to consider (e.g. detection and

anomaly removal, excavation and sifting, land use controls, etc.)

o Identify the appropriate removal depth based on data from the site, the MEC HA

and MC risk assessments, and the future land use

o Assemble the remedies into alternatives and screen the alternatives as

necessary, to reduce the overall number of alternatives to be forwarded for more

detailed analysis.

o Identify ARARs

• Conduct a detailed analysis of remedial alternatives

o Refine the alternatives further, as necessary

o Analyze the alternatives against the nine NCP criteria, the MEC HA and MC risk

assessments

o Compare the alternatives against each other

Based on the alternative analysis performed in the FS, the Navy, with regulatory coordination,

will select a proposed remedy that will be described in a Proposed Plan for public review and

comment. Comments and input obtained on the Proposed Plan will be addressed as necessary

during the development of a Record of Decision (ROD) or other Decision Document (DD) that

will define response requirements for the MRS or AOCs within the site.

RPM Note: The details for scoping a Proposed Plan and Record of Decision are not

included in this scope, but the RPM can choose to add it if it is appropriate for your site.

Depending on the specific need at the site, a Community Relations Plan (CRP) may also be

developed as part of this SOW. If not developed under this SOW, a CRP should be provided to

support this and other phases of the MRP at the site. The CRP will:

• Provide the public an opportunity to express comments on and provide input to

technical decisions;

• Inform the public of planned and ongoing actions; and

• Help identify and resolve conflicts.

3.0 SITE BACKGROUND

3.1 Location

[Describe the location of the site and provide a brief description of the terrain and vegetation,

any existing buildings or infrastructure, photo(s), and any other information to help describe the

general location and attributes for the study area. Provide references (if available) to reports or

other information that would be relevant to the level of effort required to complete tasks, such as

geophysical surveys and intrusive investigation, that are assumed to be part of the RI.

3.2 History

[Provide a brief history of the site and the reasons, known or suspected, for the potential

presence of MEC/MC. Add subsections if there are specific areas of known MEC/MC and

describe the types of munitions and filler if known. Include information on the source of

MEC/MC at each site (disposal, range, manufacturing, etc). Depending on the extent of

information available concerning the site, it may be appropriate to reference existing reports or

documents rather than providing a complete summary in the SOW].

6

RPM Note: The RPM should be clear in these sections whether the site undergoing the

RI/FS is an MRA, MRS or multiple MRSs. This general breakdown should have resulted

from the PA/SI phase and the contractor will need to understand the limits of the study.

The Navy may only be interested in remediating a single MRS within an MRA that

contains multiple sites and this point should be clear in this SOW.

It is important to state the pertinent MEC use history including the types of munitions

used, types of operations (e.g., OB/OD activities, firing points, impact areas, etc.), past

findings, Archive Search Reports (ASR) results, past response actions, military

Explosives Ordnance Disposal (EOD) unit reports, expected munitions, expected depths

and extents if established, as well as any other pertinent information on MEC uses at the

site from the PA/SI reports. RPMs are encouraged to reference pertinent reports or

documents that detail the history of the site and the degree of information available

concerning MEC incidence at the site. For ranges, it is important to provide any known

information on firing lines and target locations as well as the types of munitions used at

the site. The penetration depth will be a key factor in developing your detection and

clearance criteria. For non range sites, you should consider any other information that

may determine the maximum depth that MEC is anticipated to be found. This can be

based on geology, land filling activities, historic documents or various other sources.

While this is not always available, it can be very useful in focusing the investigation.

3.3 Safety

MEC represents a safety hazard and may constitute an imminent and substantial endangerment

to personnel and the local population due to its explosive potential. All activities involving work

in areas potentially containing MEC hazards shall be conducted only after receiving the

endorsement of NOSSA/MARCORSYSCOM and the approval of the DDESB. NOSSA and

MARCORSYSCOM are designated by OPNAV 8020.15/MCO 8020.13 to provide review and

oversight of their respective munitions response projects. Details regarding explosives safety

criteria for both Services are contained in NAVSEA Ordnance Pamphlet (OP) 5. Details

regarding munitions response actions are contained in NOSSAINST 8020.15(series), Enclosure

(3) of which describes how to write an Explosives Safety Submission (ESS). The contractor will

perform all work in accordance with the approved ESS. Non-intrusive work done at an MEC site,

outside of an ESS, will require a NOSSA/MARCORSYSCM determination that an ESS is not

required per NOSSAINST 8020.15 (series), Enclosure (2).

RPM Note: OP 5, Vol. 1 and NOSSAINST 8020.15(series) are the two key documents that

will govern explosives safety on DON sites. Marine Corps sites may follow this

instruction with the approval of COMMARCORYSCOM (PM Ammo). Technical Paper (TP)

18 from DDESB provides the personnel qualifications and experience requirements for

the contracted UXO personnel who will be performing the work. Work that includes the

intentional contact with MEC, or intrusive operations in areas known or suspected to

contain MEC, will require review and endorsement of an ESS by

NOSSA/MARCORSYSCOM and approval by the DDESB. A separate site approval request

is not required, but is part of the ESS. Up to a 6-month lead time is required for

NOSSA/MARCORSYSCOM review and DDESB approval of an ESS and must be

considered in scheduling of the RI. Advance notification to NOSSA/MARCORSYSCOM of

an anticipated ESS is encouraged to expedite reviews and revision necessary prior to

approval. The RPM should work closely with the MRP Work Group member for advice on

MRP projects. NOSSA’s phone number is 301-744-4450. MARCORSYSCOM’s phone

7

number is 703-432-4824. A discussion of the requirements for an ESS is provided in

sections covering intrusive work.

3.4 Chemical Warfare Material (CWM)

The site is not suspected to contain Chemical Warfare Materiel (CWM). However, if suspect

CWM is encountered during any phase of site activities, the contractor shall immediately

withdraw upwind from the work area, secure the site and contact the Navy RPM. The contractor

shall maintain site security until written direction is provided by the Navy regarding the

procedure to be followed for performing further RI/FS work at the site. The RPM will coordinate

with NOSSA/MARCORSYSCOM.

RPM Note: It is assumed the CWM is not expected to be encountered at most MRP sites

and that this disclaimer is appropriate. The level of planning and protective measures

required for projects that may result in encounters with CWM is significantly greater than

projects without CWM.

3.5 Sites with Potential MEC/MC

3.5.1 Site 1

[Site 1, Former (OB/OD, Bombing, Firing, Small Arms, etc.) Range, comprises XYZ acres and is

located in the (where) portion of the MRA. It was used for (destruction of military munitions

including small arms, pyrotechnics, white phosphorus (WP), rockets, grenades and artillery

ammunition, bombing practice, etc.) for X years. Describe the circumstances surrounding the

MEC/MC activities in sufficient detail so that the bidders will understand the circumstances of

the site. According to the PA/SI, historical records review, etc., the following MEC/MC are

associated with this site:

• Small Arms

• Pyrotechnics

• Everything else in the inventory

[Provide a description of the property, for example: The property is (hilly, relatively flat,

mountainous, etc.) with (dense, sparse, etc.) vegetation. A creek runs through the property from

SE to NW and the land on either side of the creek for approximately 100 feet is very wet and

cannot be traversed by vehicle. etc. Include a description of any manmade infrastructure that is

on the property.]

3.5.2 Site 2

[Same information for each of multiple sites, if multiple sites are part of the RI]

RPM Note: The purpose for the site descriptions is to provide the contractor with as

clear a picture of the property as possible. A description of the MEC activities is essential

so that they can evaluate the best possible investigation techniques to recommend. A list

of the types of MEC is necessary to determine which detection technology (e.g.,

magnetometer, electromagnetic (EM), or other) will perform the best. The description of

the property and infrastructure is necessary to evaluate what sort of platform (e.g., man

8

portable, towed, other) to use to transport the geophysical sensors and which type of

positioning (e.g., GPS, fiducial, other) may be most effective. It is also important for the

RPM to determine if the site will have to be cleared of vegetation prior to field work.

The RPM is encouraged to provide references to documents and information that may

provide a more detailed account of site conditions and history than can be provided in

the site description in the SOW. In addition, a scoping meeting should be included with

the contractor prior to their development of a proposal to allow the contractor to obtain

all necessary data for development of the proposal. In the event that data necessary to

accurately estimate the level of effort to perform the RI is not available (e.g., number of

anomalies per acre in the site) the RPM and contractor should agree to the assumptions

that will be used in development of the proposal.

The selection of the most appropriate MEC detection technology for conducting a

response action is not a simple task for two reasons: (1) there is not a currently accepted

“best” tool that offers a high degree of effectiveness, ease of implementation, and cost-

effectiveness in every situation; and (2) the “best” geophysical detector in one

geological, topographical, and vegetative environment may not work well in a different

environment. In the past, the accepted method for determining which is the best

munitions detection technology for a particular MRS was to design and construct a

geophysical prove-out (GPO) test bed and then test a variety of instruments on the GPO

to determine their probability of detection and to establish a confidence level in that

probability. This, however, is generally considered to be outdated and a GPO is not

needed for most sites. The method now being advocated is the Geophysical System

Verification (GSV) which is discussed in the following paragraphs.

Background information on detection technologies can be found in the Survey of

Munitions Response Technologies by ESTCP, ITRC, and SERDP; June 2006. This

document provides an overview of the current status of technologies used for munitions

response (MR) actions and, where possible, evaluates and quantifies their performance

capabilities. This document also provides project managers and regulators an

understanding of the performance capabilities of available technologies under real-world

site conditions and should be used in conjunction with the process for establishing

project DQOs. Background information on the GSV can be found in Geophysical System

Verification (GSV): A Physics-Based Alternative to Geophysical Prove-Outs for Munitions

Response by ESTCP; July 2009.

The evaluation and cleanup of current and former military sites contaminated with buried

munitions relies on two well-understood geophysical technologies to detect the

munitions: magnetometry and electromagnetic (EM) induction. As these technologies

were introduced in munitions response projects, the GPO was developed to determine

whether the geophysical data collected would meet project objectives. Over the last 15

years, numerous GPOs have been performed on a variety of site conditions, and a

significant body of knowledge has accumulated documenting the performance of these

technologies. This accumulated understanding, along with the recognition that magnetic

and EM responses of munitions may be predicted reliably using physical models,

presents the opportunity for both streamlining and enhancing the GPO with a more

9

rigorous physics-based approach. ESTCP in collaboration with the military Services,

state and federal regulators, and the National Association of Ordnance and Explosive

Waste Contractors (NAOC) has designed a new approach, geophysical system

verification (GSV), as a physics-based alternative to GPOs. Using the GSV process, the

resources traditionally devoted to a GPO are reallocated to support simplified, but more

rigorous, verification that a geophysical system is operating properly, as well as ongoing

monitoring of production work. The two main elements are:

1)

A

n instrument verification strip (IVS) containing a handful of targets (pipe

nipples of various sizes) replaces the traditional GPO, which consists of several

tens to a hundred or more targets. The objective of the IVS is to verify on a dail

y

basi

s that the geophysical survey system is operating properly. The IVS target

s

shoul

d be observed in the data with signals that are consistent with bot

h

m

easurements and physics-based model predictions. Adjacent measurements of

the site noise are used to determine whether targets of interest can be detect

ed

r

eliably to their depth of interest under the site conditions.

2)

I

n the blind seeding program, the production site is seeded with targets (pipe

nipples) at surveyed locations that are blind to the data collection and processing

teams. The objective is to provide ongoing monitoring of the quality of the

geophysical data collection and target selection process as it is performed in t

he

production survey.

RPMs should note, however, that the GSV is not applicable to so-called “black boxes.”

This will include proprietary devices for which sensor details are not divulged and any

other system whose operation, in terms of both hardware and processing, is not well-

documented. Likewise, the GSV will not be appropriate for technologies based on

completely different physical phenomena, where a GPO may be required. RPMs should

also note that some aspects of the seeding will not be practical at all sites. For example,

seeds may be difficult to apply to transects and meandering path surveys, where 100%

survey coverage is not required and the exact locations of survey lines is not known in

advance.

T

he Geophysical System Verification: A Physics-Based Alternative to Geophysical

Prove-Outs document can be downloaded from the ESTCP website at

www.estcp.org

RI DOCUMENTS AND FIELD WORK

R

PM Note: For sections 4.0 and 5.0 we have included below a list of the typical types of

investigation/analysis an RPM may do at a MRP site during the RI/FS phase. The RPM

should adapt this SOW from the parts outlined below and apply them to your specific site

as needed. Each component is described in greater detail at the end of this SOW and

should be cut and pasted in as needed. The documentation required for each component

is highlighted below and described for each at the end of this SOW template. The

hyperlinks to each section are below, just press the ctrl key and click to go to the

relevant section.

The primary goals of the RI are to determine the nature and extent of contamination and

to use this data to develop a baseline exposure assessment for the site. The exposure

assessment considers potential threats to human health and the environment from site

10

contaminants (including MC) as well as potential exposure to explosive safety hazards at

MRP Sites. The baseline exposure assessment is used to determine if an unacceptable

health/ecological risk or explosive hazard exposure exists at the site. If an unacceptable

risk or explosive hazard exposure is determined to exist, the FS evaluates the array of

remediation alternatives that will be considered to address this situation and select the

preferred alternative.

In developing the plans for the RI/FS, the RPM should follow guidance provided by U.S.

Environmental Protection Agency, 2006a, Guidance on Systematic Planning Using the

Data Quality Objectives (DQO) Process (EPA QA/G-4). Use of this guidance will focus

data collection activities included in the RI/FS to ensure that only data needed to support

decision making an alternative analysis is collected and prevent needless expense and

time collecting data that does not contribute to RI/FS objective.

The RPM should coordinate with stakeholders prior to developing this SOW to outline

the site requirements and DQOs, which will help determine the most appropriate

components to include for your site. In many cases, the process of determining the

DQOs and defining the field data necessary to meet these objectives will require an

extensive planning effort to ensure that input from regulatory agencies and stakeholders

has been appropriately considered. This is particularly true for complex projects that are

managed under Interagency Agreements with Federal and State regulatory agencies. At

such sites, draft RI/FS work plans are commonly a primary deliverable requiring State

and Federal regulatory agency approval prior to initiation of any RI/FS field work.

In cases where an extensive planning effort is required to develop the RI/FS work plans

and define the DQOs and field work and data collection requirements for the RI and

subsequent FS, the RPM should consider scoping the planning effort for development

RI/FS work plans separately from execution of the work plans. Separate scoping of the

work plan development phase of the project will allow the RPM and contractor to better

define the field work that will be required to complete tasks identified in work plans that

have been approved by regulatory agencies.

One issue that has appeared in developing plans for fieldwork is poor quality control of

the initial document generated by the contractor. These plans should be reviewed by the

contractor’s quality control personnel prior to submission to the Navy. If obvious

mistakes are included in these initial plans (e.g. SOPs copied and pasted from another

project without any adjustment to the specific site, etc), the RPM should consider

whether a contractor should receive a reduced award fee, or low evaluation score.

4.0 RI DOCUMENTS

RPM Note: The hyperlinks to each section are below in section 5.0, just press the ctrl key

and click to go to the relevant section and edit, copy, paste in the relevant information.

5.0 RI FIELD WORK

Sampling for Munitions Constituents (MC)

Documents: RI Work Plan, HASP, FSAP, QAPP

Other issues: Anomaly avoidance measures, ESS determination

Geophysical Investigation without Intrusive Investigation

Documents: RI Work Plan, HASP, PQCP, GPO or GSV Plan

11

Other issues: Site preparation, Govt. QA Plan, anomaly avoidance

measures, ESS determination

Geophysical Investigation with Intrusive Investigation

Documents: RI Work Plan, HASP, PQCP, GPO or GSV Plan, ESS

Other issues: Site preparation, Govt. QA Plan, MEC disposal plan,

MPPEH management

Mag, Flag, & Dig (Magnetometer detection and marking without geophysical

mapping followed by intrusive investigation)

Documents: RI Work Plan, HASP, PQCP, GPO or GSV Plan, ESS

Other issues: Site preparation, Govt. QA Plan, MEC disposal plan,

MPPEH management

RPM Note: A MEC UFP-QAPP template is available on the MR portal. The template

provides modified UFP-QAPP workheets with a discussion of the considerations

necessary to generate a MEC UFP-QAPP.

Likewise, an example MEC UFP-QAPP is

provided on the MR Portal. Also included are the Technical Management Plan for the site

and the Standard Operating Procedures which are appendices in the MEC UFP-QAPP.

These documents are provided so that the level of detail that was developed in each

document can be understood. The work plan contains a minimum amount of information

with the purpose of directing the reader to the MEC UFP-QAPP.

A Quality Assessment SOW template is also on the MR Portal.

This SOW template is

intended to assist the RPM in contracting with either the Naval Explosive Ordnance

Disposal Technology Division (NAVEODTECHDIV) or an independent third party to

perform the Quality Assessment role during munitions response (MR) actions.

6.0 Treatability Study

RPM Note: A Treatability Study involves testing and evaluating a treatment technology to

determine the effectiveness of that technology at a particular site or to establish site-

specific design parameters. These studies can be applied to remedy screening,

selection and design, and should be carefully selected to meet DQOs for the project. The

additional costs for conducting treatability studies are often justifiable as these studies

can significantly reduce the uncertainties that are sometimes associated with innovative

technologies.

Treatability studies may be needed during the RI/FS when sufficient information for

technology cost and performance, under site-specific conditions, is not available. This

information is necessary for applying the nine NCP criteria for evaluation of alternatives

for the feasibility study. A treatability study should verify whether the technology is

capable of meeting the cleanup goals or other specified performance objectives.

Following a decade of research and development, classification technology of MEC has

now been successfully demonstrated on several live sites under the Environmental

Security Technology Certification Program (ESTCP).

This new process is used to

classify subsurface anomalies as those likely to be a MEC item which must be removed

or is likely to be a non-MEC item which may be left in the ground. Using these advanced

classification sensors to analyze data over previously-detected anomalies has shown

12

that it is possible to correctly identify 75-90+% of clutter while retaining all of the MEC on

the dig list.

RPMs should consider if this technology is applicable at their site and perform a

treatability study to define such things as production rate, areas that are suitable for

classification technology, the overall economics of implementing the classification

process, and the QA/QC requirements for the new sensors. More information on the

classification technology can be found on the SERDP ESTCP website and in the

guidance on their website titled “Implementing Advanced Classification on Munitions

Response Sites: A Guide to Informed Decision Making For Project Managers, Regulators,

and Contractors” It may be prudent to have a scoping meeting with the contractor to

discuss which classification technology treatability studies will be performed and where

they will be performed.

The objective of this treatability study is to determine if classification technology is a viable

treatment option and can meet remedial action objectives for Site 1 or portions of Site 1.

Activities associated with this project include the following:

• Development of a treatability study workplan. The workplan should, among other things,

clearly describe: the experimental design, the treatability study goals, the QAPP, data

management and interpretation, and reporting.

• Installation and development of appropriate QC processes and measures such as

instrument verification strip and blind seeding with XXX size industry standard objects

• Collecting advanced geophysical sensor data over XXX anomalies using XYZ system;

• Processing the data, including feature extraction and classifier application to develop a “dig

list”

• Conducting intrusive investigation to verify performance of the classification technology on

XXX anomalies and manage any MEC/MPPEH derived from the study

• Performing a detailed analysis of classification technology alternatives including which

advanced sensor is appropriate for the site areas and the estimated costs to implement the

classification technology. The detailed analysis of alternatives which will consist of an

individual analysis of each alternative against a set of the CERCLA nine evaluation criteria

and a comparative analysis of all options against the evaluation criteria with respect to one

another.

• Preparing a treatability summary report or appendix in the RI/FS report which documents the

results of the treatability studies and QA/QC for the study

"

The contractor shall use and refer to EPA guidance for this treatability study. Specifically, EPA’s

“Guide for Conducting Treatability Studies under CERCLA, 1992"

RPM Note: the above language assumes that an ESS is in place. If it isn’t, modify the

language to incorporate appropriate ESS development language from section 5.

7.0 RI/FS REPORTS and CRP

The results of the site characterization shall be documented in an RI/FS Report. The RI/FS

report shall be submitted in preliminary/internal draft for Navy review, draft for full regulatory

review, and final after comments are addressed. The contractor will develop a range of

MEC/MC management alternatives that will remediate or control any MEC/MC remaining at the

13

site, as deemed necessary in the RI, the MEC HA, and the MC risk assessments to provide

adequate explosives safety, and protection of human health and the environment. The potential

alternatives should encompass, as appropriate, a range of alternatives in which MEC/MC

removal is used to reduce the toxicity, mobility, or volume of MEC/MC but vary in the degree to

which long-term management of residual/remaining MEC/MC is required. One or more

alternatives involving land use controls and a no-action alternative should also be included.

The potential technologies and process options should be combined into location-specific or

site-wide alternatives.

The contractor will meet with the Navy to discuss which alternatives will

be evaluated in the detailed analysis and to facilitate the identification of action-specific ARARs.

The contractor will conduct a detailed analysis of alternatives which will consist of an individual

analysis of each alternative against a set of the CERCLA nine evaluation criteria and a

comparative analysis of all options against the evaluation criteria with respect to one another.

The individual analysis should include: (1) a technical description of each alternative that

outlines the MEC/MC management strategy involved and identifies the key ARARs associated

with each alternative; and (2) a discussion that profiles the performance of that alternative with

respect to each of the evaluation criteria. A table summarizing the results of this analysis should

be prepared. Once the individual analysis is complete, the alternatives will be compared and

contrasted to one another with respect to each of the evaluation criteria.

RPM Note: The RI report can be combined with the FS report to form an RI/FS report, but

the RI and FS reports also can be submitted separately. The RI section of the RI/FS report

should present the methods used for the RI, the updated CSM resulting from the

investigation, the results of the MEC HA and MC risk assessment, a determination of

whether further remedial action is needed, and if so, the recommended remedial action

objectives. The primary focus of the FS report is to ensure that appropriate remedial

alternatives are developed and evaluated in such a manner that the information can be

presented to a decision-maker and an appropriate remedy selected. Development of

alternatives shall be fully integrated with the site characterization activities of the RI, and

the combined RI/FS leads to the selection of an optimal response action for the site.

The recommended format to follow for the RI and FS sections of the report are provided

in Table 8-1and Table 8-3 of the Department of the Navy Environmental Restoration

Program Manual. The RPM should direct the contractor to update this format to include

MEC related information.

The MEC Removal, Treatment and Residual Processing tables at the end of this

document help to provide a list of available alternatives that may be evaluated in the FS.

These tables are from the USACOE, MEC Detection, Recovery, And Disposal Technology

Assessment Report.

Community Relations Plan (CRP)

The contractor will be responsible for setting up and documenting community interviews in order

to produce the CRP. Interviews will be conducted with FEC personnel and local officials,

residents, public interest groups, and other interested or affected parties to ascertain community

concerns, community information needs, and how or when citizens would like to be involved in

the CERCLA process. The contents of the CRP should include the following: background and

history of community involvement at the site including local activity and interest plus key issues;

site history including environmental history; objectives of the ER Program; community

involvement activities to meet the ER Program objectives; and a list of officials,

14

citizen/community groups, and media contacts. The CRP shall be submitted in

preliminary/internal draft for Navy review, draft for full regulatory review, and final after

comments are addressed. The community involvement program shall be conducted in

accordance with the RAB Rule (Federal Register 5/12/06) and the RAB Rule Handbook (DoD,

March 2007).

RPM Note: The Community Relations Plan documents the history of community

relations and the issues of community concern at a site. It describes the objectives of the

community relations activities and how these objectives will be met and includes a

discussion of planned community interviews, fact sheets, and public meetings. The Navy

Environmental and Natural Resources Program Manual (OPNAVINST 5090.1B, 01

Nov.1994) and Marine Corps Environmental Compliance and Protection Manual (MCO

P5090.2A, 10 July1998) and the RAB Rule Handbook (DoD, March 2007) provide public

participation guidance.

DON’s policy is to prepare CRPs for specific installations rather than for specific actions,

the CRP may have additional requirements beyond those specified in CERCLA and,

therefore, the RPM should check the installation’s CRP to ensure that all requirements

are being met. If necessary a CRP should be developed. Otherwise, community relations

activities should support the existing CRPs (most cases).

8.0 PROJECT MANAGEMENT

The contractor shall perform project management activities necessary to maintain project

control and to meet reporting requirements, including but not limited to the following:

8.1 Schedule

The contractor will prepare a comprehensive project schedule which shall be due within [insert

weeks/months] after project award. The schedule will be prepared using MS Project and

provided in hardcopy and electronically in native format and may be required as a .PDF file as

well. The contractor shall update the schedule monthly and provide this as an electronic

deliverable (email only for this electronic deliverable) to the RPM. The contractor shall

coordinate critical deliverable dates with the RPM. [Insert any critical schedule requirements

here, such as Federal Facility agreements or other agreements]

8.2 Meetings and Project Coordination

8.2.1 Pre-Bid and Kickoff Meetings

A pre-bid site visit [will/will not] be conducted by the Government. The pre-bid site visit will

occur, [provide the date, time, assembly place, etc. for the visit]. The Government will prepare

an abbreviated Site Safety and Health Plan to cover the site visit and, if the area has known

MEC, provide a UXO-qualified safety escort. If necessary, a request for an ESS determination

will be prepared by the government for submittal to NOSSA/MARCORSYSCOM prior to the site

visit.

RPM Note: The need for a pre-bid site visit will depend on the information available from

the PA and/or SI and the contractor’s familiarity with the site and your selected contract

15

mechanism. A pre-bid site visit may be required for contract mechanisms where the SOW

is sent to several bidders.

The contractor shall plan to attend a kickoff meeting/formal site visit at [insert site or Facilities

Engineering Command (FEC)]. Attendees of this meeting may include the Navy RPM,

Environmental Coordinators and others from the site and various FEC personnel. At a minimum,

the contractor’s Project Manager and/or Technical Lead for this project shall attend. Regulators

and stakeholders may be included as determined by the RPM. The agenda for this meeting will

include discussions of roles and responsibilities, emergency response, health and safety,

access to the site, project schedule, explosives safety, contracted deliverables, investigation

methodology, and other issues related to the delivery order. The contractor shall provide a

written meeting agenda to all invited participants not less than [insert number of days] prior to

the scheduled meeting, coordinate with the RPM to arrange meeting facilities, and provide

invited participants written meeting minutes within [insert number of days] after the meeting.

8.2.2 Project Meetings

The contractor shall coordinate and attend [insert number] additional meetings at [insert

location] to be held at the discretion of the RPM. Attendees normally include regulators and

stakeholders. To the extent possible, it is recommended to schedule project meetings during

times when the contractor’s staff are already visiting [insert location] for project-related duties.

Teleconference and web enabled meetings may also be necessary. The contractor is

responsible for agendas and minutes of all meetings. The contractor will provide an agenda, via

e-mail, no less than [insert number] days prior to any meeting to participants identified by the

RPM. For meetings involving review of a deliverable, include a brief synopsis of the latest

comments and recommendations for the deliverable. The contractor will provide invited

participants written meeting minutes within [insert number] days after the meeting.

9.0 SUBMITTALS AND CORRESPONDENCE

9.1 Format for Reports

The final RI/FS Report shall consist of a black and white master adequate for printing and

copying on 8 1/2" X 11" paper size. It is permissible to use foldout sheets as long as the eleven-

inch vertical dimension is retained. Maps should be in color to easily distinguish the various

features, however, the contractor must ensure that critical data are not lost if the map is

reproduced in black and white. Deliverables, other than Draft, shall contain a “Response to

Comments” (RTC) table indicating how each regulatory agency comment was addressed.

All

draft and final submittals must be letter quality; all pages must be numbered with chapter

number followed by page number (1 1, 1 2, 1 3, 2 1, 2 2, 2 3, etc.). Appendix documentation

submittals must be letter quality with all pages numbered (A 1, A 2, B 1, B 2 etc.).

9.2 Electronic Deliverables of Records

The electronic version/file of the preliminary/internal draft, draft, and final after comments are

addressed shall be submitted in both A) the native format, which Navy prefers be a Microsoft

product, and B) Adobe Acrobat PDF (or compatible) format. The PDF version of all final

deliverables (other than raw analytical and databases) must be a complete, mirror image of the

hardcopy, and include appendices, maps, signature pages, etc. At completion of the project with

the Final RI/FS Report submittals, the contractor will provide an electronic deliverable with a

copy of all reports, meeting minutes, point papers, maps and map databases, and briefings. All

16

electronic submittals will be certified “virus free” and include the statement “virus free” on the

disk or transmittal message. The contractor shall verify, with the RPM, the appropriate data

management requirements and electronic data deliverables.

9.3 Spatial and Non-Spatial Data Standards

RPM Note: NIRIS is designed to manage both IR and MRP site data using GIS and other

end user tools. Training on the use of NIRIS is recommended and available upon request

for both RPMs and contractors. Coordinate with your local NIRIS Workgroup member

regarding access and training for NIRIS and mapping needs. In the fall 2012 timeframe,

NIRIS will be linked to the Regional Shore Installation Management System (RSIMS) for

local basemap data, real estate parcel information and aerial photography for most sites.

All ER data must be submitted via the NIRIS Electronic Data Deliverables (NEDDs) and

automated data checker. NIRIS should be used for MR projects mapping needs,

however, if there is an existing, legacy system with data to migrate to NIRIS, or

specialized applications or tools, talk to your local NIRIS Workgroup member.

NIRIS is

located on the NAVFAC Portal by navigating to the “employees” (i.e., Private Portal) side,

clicking on “eTools”, clicking on “more eTools” and scrolling down to NIRIS.

Spatial data such as maps, CADD drawings, aerial photos, etc. may be required in

support of the project. All CADD and Geographic Information Systems (GIS) graphics

deliverables shall be compliant with the latest Navy and DOD spatial data requirements, i.e.,

Naval Installation Restoration Information Solution (NIRIS) Non-NEDD Deliverable Submittal

Guidelines SOP).

9.4 Geographic Information Systems (GIS) Deliverables

MRP data is inherently spatial in nature. A web-based GIS shall be used to facilitate decision

making, perform analysis and visualize results, to ensure effective cleanup decisions are made

in cooperation with the Navy, regulators, and other stakeholders. GIS data may include: past

and present land uses, site conditions, historical photographs, land use controls (LUCs),

geophysical data, MEC findings data, and MC data collected throughout the RI/FS. The

Government will provide the contractor access to NIRIS and provide the initial base mapping

data and information on the format of the data. The NIRIS Non-NEDD Deliverable Submittal

Guidelines SOP contains detailed requirements and specifications and should be used for all

GIS deliverables.

The contractor shall update and manage the project GIS in NIRIS, or if needed, an export of the

NIRIS data using a local machine running ArcGIS or ArcInfo. Any project related spatial data

including maps, models and associated collected or created data must then be submitted back

to NIRIS according to the NIRIS Non-NEDD Deliverable Submittal Guidelines SOP. This would

include daily geophysical data, MEC related items found during the investigation, positively

identified MEC, positively identified archeological sites, environmental sample locations,

inaccessible areas such as brush piles, fence lines, areas of bare rock, etc.

9.5 Electronic Data Deliverables

All tabular data such as MC analytical results by location, geophysical anomaly or ordnance

information shall be provided using the appropriate NIRIS Electronic Data Deliverable according

to the NEDD Standard Operating Procedure using the NIRIS web-based data checker.

17

9.6 Administrative Record File (ARF)

The contractor will establish or maintain an ARF during this phase of the project. All documents

will be prepared and indexed for inclusion in the ARF.

RPM Note: Information regarding the establishment of AR Files can be found in “Final

Guidance on Administrative Records for Selecting CERCLA Response Actions” OSWER

9833.3A-1, Dec 1990 and in NAVFAC’s “CERCLA Interim Administrative Records

Management System Users Guide” UG-2024-ENV, Dec 2000. In addition, NAVFAC Atlantic

and Pacific, and many FECs have Records Mangers to help RPMs maintain the ARF and

Site File.

Contractor and ERP Navy personnel generated ERP documents (commonly referred to as

“deliverables”) for NAVFAC Mid-Atlantic, Midwest, Southeast and Washington

installations will be sent to the designated Regional Data Manager (RDM) for that

respective region. The responsible NAVFAC party or a subcontractor acting on behalf of

NAVFAC will provide the RDM a paper, electronic and ‘native files’ copy of each

deliverable. Each paper copy will be complete including signed signature page. The

electronic copy shall be in Acrobat Adobe Portable Document Format (PDF) and will

adhere to the scanning and bookmarking requirements outlined in the Environmental

Restoration Recordkeeping Program Manual, Appendix K. All ERP documents

associated with the Administrative Record File, Post Decision File and Site File will be

prepared and submitted in accordance with the NAVFAC Environmental Restoration

Recordkeeping Manual. To view the ER Recordkeeping Program Manual, click on the

following URL:

https://portal.navfac.navy.mil/portal/page/portal/navfac/navfac_ww_pp/navfac_nfesc_pp/

environmental/erb/resourceerb/rkm_9-1-09.pdf

9.7 Public Affairs

The contractor shall not disclose any data resulting from actions in this contract to the news

media, the public, regulatory agencies, or any other non-project-involved personnel. The

contractor shall refer all press or public contacts to the RPM. The contractor may not distribute

reports or data to any other source, unless specifically authorized, in writing, by the Public

Affairs Officer in accordance with NAVFAC Instruction 5720.10A. All project-related materials

become permanent property of the United States Government.

9.8 Distribution

Deliverables must be approved by the RPM prior to distribution (see Table 1). [RPM should

make below chart specific to your SOW]

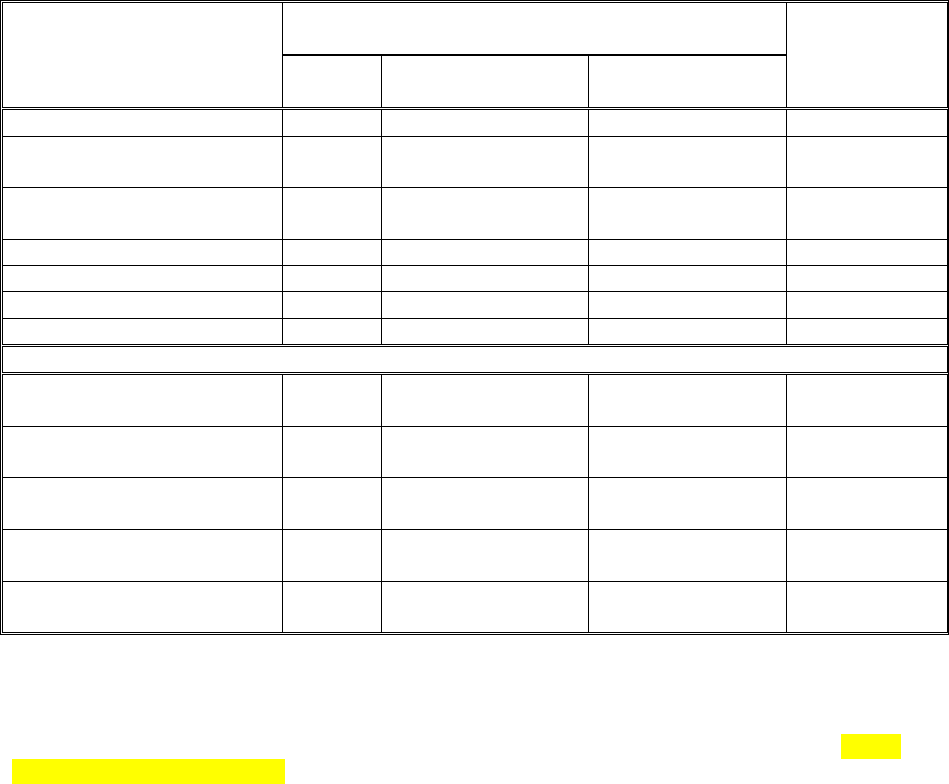

Table 1. Schedule of Deliverables

Deliverable

# of Hard Copies/Disks

Due Date

RPM

Activity/

Installation

Regulatory/

Other

RI/FS Work Planning Documents

Project Schedule

1/1

0/0

0/0

2 weeks from

Table 1. Schedule of Deliverables (Continued)

18

Deliverable

# of Hard Copies/Disks

Due Date

RPM

Activity/

Installation

Regulatory/

Other

award

ESS

1/1

1/1

2/0

30 days from

award

Draft RI Work Plan

0/3

0/0

0/0

30 days from

award

Gov’t comments

1 week

Draft Final RI Work Plan

All review comments

Final RI Work Plan

1/1

1/1

0/0

1 week

RI/FS REPORT

Draft RI/FS Report

1/1

1/1

0/0

180 days from

award

Navy Review/comment

200 days from

award

Draft-Final RI/FS Report

1/1

1/1

1/1

220 days from

award

All Review/Comment

250 days from

award

Final RI/FS Report

2/2

1/1

1/1

280 days from

award

10.0 SPECIAL CONDITIONS

The contractor will obtain written approval from the appropriate installation personnel [insert

location and phone number] prior to obtaining photographic records, still or motion pictures, and

aerial or ground photographs; in accordance with Public Law 18 U.S. Code 795 and applicable

Station Regulations. The Government may provide a representative to act in an advisory

capacity to prevent unauthorized disclosure of classified information.

Any oral directions, instructions, explanations, commitments and/or acceptances given by any

government employee to the contractor, shall not be construed by the contractor as a change in

scope to this delivery order. Any change in scope of work must be issued to the contractor, in

writing, by the Contracting Officer in order to be binding to the government.

The contractor shall provide copies of all project correspondence to the RPM as well as

synopses of all phone conversations with regulators in a timely manner. The RPM is to be

copied on all electronic correspondence with FEC and Installation/Activity representatives, and

others as appropriate and as requested by the RPM.

The contractor shall organize, furnish, maintain, supervise, and direct a work force, which, within

the limitations of the provisions of the contract, is thoroughly capable and qualified to effectively

perform the work set forth in this delivery order. The contractor will ensure that personnel have

been appropriately trained for the tasks and duties assigned. The contractor will maintain and

provide upon request, records of training and qualifications of individuals involved in the project.

19

The contractor and his employees and subcontractors shall become familiar with and obey

installation regulations, including fire, traffic, and security regulations. Contractor personnel

employed on the installation shall keep within the limits of the work (and avenues of ingress and

egress), and shall not enter restricted areas unless required to do so and are cleared for such

entry. The contractor's equipment shall be conspicuously marked for identification.

Permit Equivalency for CERCLA On-site Response Actions: CERCLA on-site response actions

are exempted by law from requirements to obtain Federal, State or local permits related to any

activities conducted completely onsite [CERCLA Section 121(e)]. However, the substantive

provisions of the permitting regulations that are applicable or relevant and appropriate, must be

met. Expenses to obtain on-site permits that are exempt under CERCLA are not normally

reimbursable.

Identification badges and vehicle passes will be furnished without charge; application for and

use of passes will be specified by [insert Installation/Activity ] Installation Security when issued.

Immediately report lost or stolen passes to [insert Installation/Activity ] Installation Security and,

in writing, to the Contract Specialist (CS) and RPM. Issuance will be coordinated through the

RPM.

11.0 REFERENCES

References: (RPM to determine all that are applicable and add site specific references. The

RPM should also update the list to include the most recent issuance of any document or

instruction)

• NAVSEA OP-5, Vol. 1, Seventh Revision, “Ammunition and Explosives Ashore

Safety Regulations for Handling, Storing, Production, Renovation and Shipping”.

• NOSSA Instruction 8020.15(series), “Explosives Safety Review, Oversight, And

Verification of Munitions Responses ”

• OPNAV INSTRUCTION 8020.15A/MCO 8020.13A, “Explosives Safety Review,

Oversight, And Verification of Munitions Responses” (27 Feb 2008)

• OPNAV INSTRUCTION 3500.39 series, Operational Risk Management (ORM)

method for identifying hazards

• DOD Explosives Safety Board (DDESB) Standard 6055.09-STD

• DDESB Technical Paper Number 18, dated December 2004

• Marine Corps Order P 8020.10A, “Marine Corps Ammunition Management and

Explosives Safety Policy Manual” (for work performed at USMC installations)

• Automated Quality Assessment Planning System (AQAPS)

• Department of the Navy Environmental Restoration Program Manual, August 2006

• Federal Regulation 29 CFR 1910.120, Hazardous Waste Operations and Emergency

Response (HAZWOPER)

• PA/SI report or Archives Search Report of installation

• Installation Master Plan

• IRP Initial Assessment Study/Preliminary Assessment/Site Inspection and other IRP

reports related to the site

• Environmental Baseline Survey or Environmental Condition of Property

• Integrated Natural Resources Management Plan

• Military Munitions Rule [Federal Register: February 12, 1997 (Volume 62, Number

29)]

• DOD Policy to Implement the EPA’s Military Munitions Rule (July 1, 1998)

20

• DOD 4145.26-M, DoD Contractors’ Safety Manual for Ammunition and Explosives

• DODD 4715.1E, Environment, Safety, and Occupational Health (ESOH) (March,

2005)

• DOD EDQW Guide for Implementing EPA SW-846 Method 8330B

• Comprehensive Environmental Response, Compensation and Liability Act of 1980

(CERCLA Section 120 (h) 42 U.S.C. Section 9620) and as amended by the SARA of

1986

• Community Environmental Response Facilitation Act (CERFA), Public Law 102-426

(Oct 19, 1992)

• The National Oil and Hazardous Substances Pollution Contingency Plan (NCP), Part

300, Chapter 40, CFR

• Material Potentially Presenting an Explosive Hazard (MPPEH), DODI 4140.62,

November, 2008

• USACOE, Military Munitions Response Actions, EM 1110-1-4009, June, 2007

• USACOE, Military Munitions Center of Expertise, Technical Update for Munitions

Constituents (MC) Sampling, March 2005

• USACOE, Conceptual Site Models for Ordnance And Explosives (OE) and

Hazardous, Toxic, And Radioactive Waste (HTRW) Projects, Feb 2003

• USACOE, MEC Detection, Recovery, And Disposal Technology Assessment Report,

Dec 2005

• USACOE, Implementation of Incremental Sampling (IS) of Soil for the Military

Munitions Response Program, USACE Interim Guidance 09-02, July 20, 2009

• US Navy, Conducting Human Health Risk Assessments Under the Environmental

Restoration Program (Ser N453E/10595168, 12 Feb. 2001);

• US Navy, Navy Policy for Conducting Ecological Risk Assessments (Ser

N453E/9U595355, 05 Apr. 1999)

• US Navy, Navy Human Health Risk Assessment Guidance, December 2008.

• US Navy, Navy guidance for conducting an ecological risk assessment is provided

online at

http://web.ead.anl.gov/ecorisk/

• USEPA, Handbook on the Management of Munitions Response Actions, (Draft Final

May 2005)

• USEPA/DoD/DoI, Munitions and Explosives of Concern Hazardous Assessment

(MEC HA) Methodology , February 2010 EPA 505B08001

• USEPA, SW 846 Test Methods for Evaluating Solid Waste, Physical/Chemical

Methods, Method 8330B Nitroaromatics, Nitramines and Nitrate Esters by High

Performance Liquid Chromatography and Method 8321A Solvent Extractable

Nonvolatile Compounds by High Performance Liquid

Chromatography/Thermospray/Mass Spectrometry (HPLC/TS/MS) or Ultraviolet

(UV) Detection

• USEPA, A Guide to Developing and Documenting Cost Estimates During the

Feasibility Study. EPA 540/R-D0/002, OSWER 9355.0-75

• USEPA, Guidance for Conducting Remedial Investigations and Feasibility Studies

under CERCLA, Interim Final (October 1988) EPA 540/G-89/004, OSWER 9355.3-

01

• USEPA, Getting Ready: Scoping the RI/FS (November 1989) OSWER 9355.3-

01FS1, NTIS: PB90-274390INX

• USEPA, The Feasibility Study, Development and Screening of Remedial Action

Alternatives (November 1989) OSWER 9355.3-01FS3, NTIS: PB90-274416INX

21

• USEPA, The Feasibility Study: Detailed Analysis of Remedial Action Alternatives

(March 1990) OSWER 9355.3-01FS4, NTIS: PB90-272675INX

• USEPA, The Remedial Investigation, Site Characterization and Treatability Studies

(November 1989) OSWER 9355.3-01FS2, NTIS: PB90-274408INX

• USEPA, Guidance for Conducting Treatability Studies under CERCLA (October

1992) EPA 540/R-92/071A, NTIS: PB93-126787INX

• USEPA, Superfund Community Involvement Handbook EPA/540/K-01/003, Apr.

2002

• USEPA, Uniform Federal Policy for Quality Assurance Project Plans Manual, March

2005

• NAVFAC Uniform Federal Policy –Sampling and Analysis Plan Template, (See your

FEC QA POC for the latest version)

• NAVFAC MEC Uniform Federal Policy –Quality Assurance Project Plan Template,

(Available on the Navy MR Portal at www.ert2.org/t2mrportal)

• ESTCP Geophysical System Verification (GSV): A Physics-Based Alternative to

Geophysical Prove-Outs for Munitions Response, July 2009

The Navy will provide an installation map of the subject property.

11.0 DEPARTMENT OF THE NAVY POINTS OF CONTACT

Remedial Project Manager (RPM):

Name:

Address:

Phone:

Fax:

Email:

Contract Specialist (CS):

Name:

Address:

Phone:

Fax:

Email:

Activity/Installation Point of Contact (POC):

Name:

Address:

Phone:

Fax:

Email:

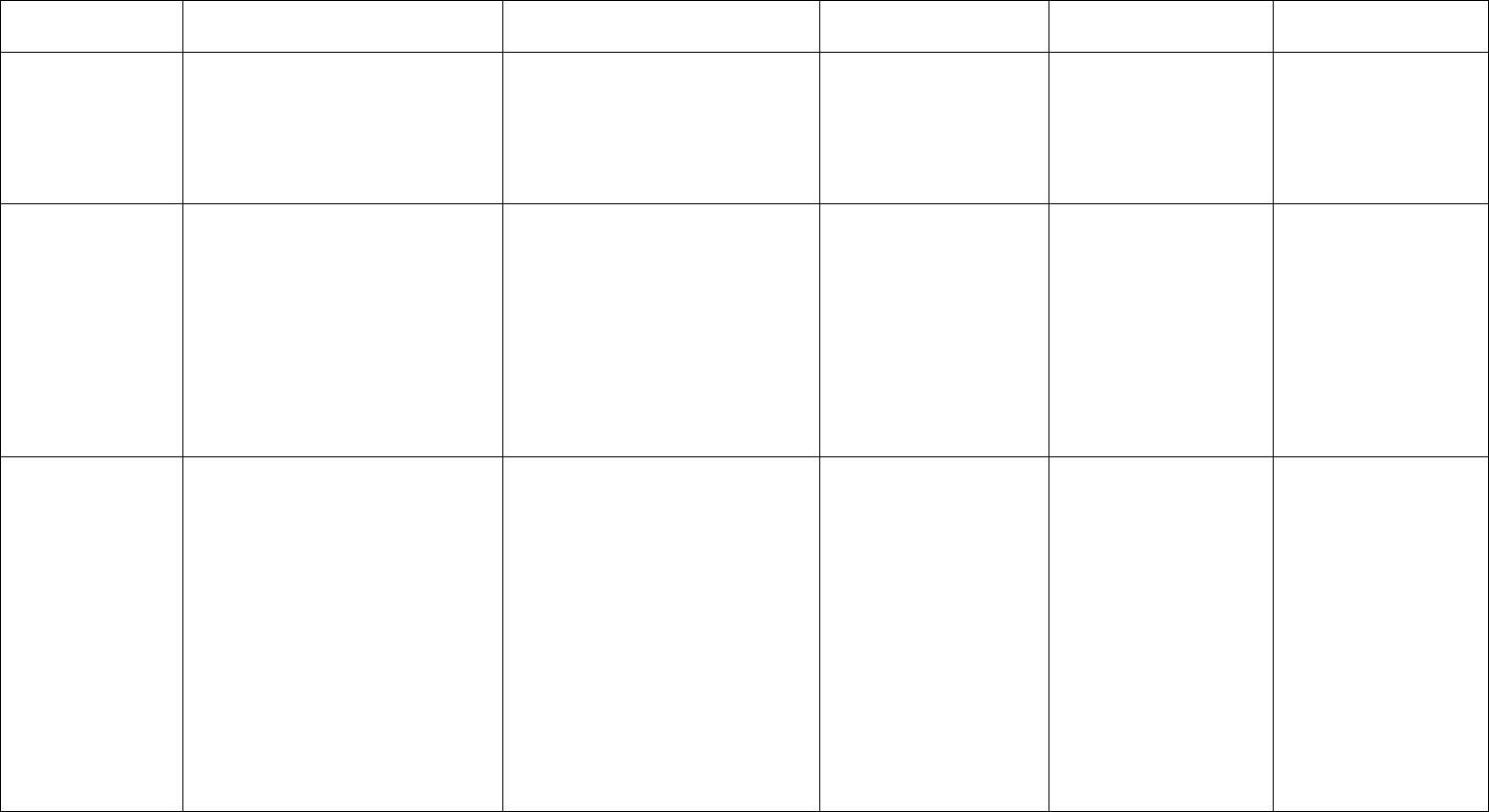

12.0 PERSONNEL QUALIFICATIONS

The contractor shall provide UXO technicians having appropriate levels of UXO expertise to

perform the work under this task order. The minimum qualifications for UXO-qualified personnel

are listed below (from the DDESB TP-18 Table 4.1).

22

DDESB TP-18 Table 4.1. Minimum Qualification Standards

Position

Description

Training

Required

(Notes 1, 2, &

3)

Minimum

Years of

EOD/UXO

Experience

(Note 4)

Special Requirements

(Note 5)

Senior UXO

Supervisor

1, 2, or 3

10 years

Significant experience in all aspects of

munitions response actions or range

clearance activities, as appropriate for the

contracted operation. Five years experience

in supervisory positions.

UXO Safety

Officer

1, 2, or 3

8 years

Experience in all phases of munitions

response actions or range clearance

activities, as appropriate for the contracted

operation, and applicable safety standards.

UXO Quality

Control

Specialist

1, 2,3

8 years

Experience in all phases of munitions

response actions or range clearance

activities, as appropriate for the contracted

operation, and the transportation, handling

and storage of munitions and commercial

explosives.

UXO

Technician III

1, 2 or 3

8 years

Prior military EOD and/or commercial UXO

experience in munitions response actions or

range clearance activities, as appropriate for

the contracted operation.

UXO

Technician II

1 or 2

------or------

3

N/A

-------or------

3 years

Prior military EOD experience

--------------------------or------------------------

Experience in response munitions response

actions or range clearance activities, as

appropriate for the contracted operation,

plus specific project/explosives safety

training.

UXO

Technician I

3

0

Successfully completed formal course of

instruction appropriate to

this skill level.

UXO-Sweep

Personnel

Equipment and

site specific

training

N/A

Safety equipment and

site specific training.

(Experience at this position is not required

for UXO Technician I certification.)

Notes:

1. Graduate of a military EOD School of the United States.

2. Graduate of a military EOD school of Canada, Great Britain, Germany, or Australia.

3. Graduate of a formal training course of instruction (see chapter 3 for detailed requirements) or

EOD assistant courses.

4. Personnel working in the commercial industry may have significant breaks between jobs. Only

actual time performing UXO-related tasks should be counted. (2080 hours = 1 man-year)

5. Divers conducting underwater detection and identification of munitions must have completed

both the basic and the underwater portions of NAVSCOLEOD (or foreign equivalent) training.

23

Sampling for Munitions Constituents (MC)

RPM Note: The section title above is hyperlinked back to the page where each of the four

different Field Work template links are located.

MCs are mixtures of explosive compounds and soils in concentrations less than 10% (by

weight) for secondary explosives and less than 2% for primary explosives. If you are doing

MC sampling in addition to other investigations, please incorporate MC sampling

information outlined in this section into your SOW.

4.1 RI Work Plan

The contractor shall prepare and submit a Draft, Draft Final and Final RI Work Plan, with the

required appendices, which describe how to implement the requirements and information

developed during the planning and scoping of this RI Work Plan. The RI Work Plan will define

project objectives, decision making criteria, and associated data needs to reach project closeout

and describe Data Quality Objectives (DQOs). The basic RI Work Plan will describe the general

methodology for performing the site MC work, including at a minimum:

• Site preparation, including vegetation removal and removal of surface metallic debris (if

required)

• Anomaly avoidance measures to be implemented

• Munitions Constituents (MC) Sampling

• Geographical Information Systems (GIS) and data management

• Investigation Derived Waste Management

4.1.1 Site Health & Safety Plan (HASP)

The contractor will prepare and submit a Site Health & Safety Plan (HASP). The HASP will contain

an Activity Hazard Analysis (AHA) for each site-specific task to be conducted. The HASP will be

appended to the Accident Prevention Plan (APP) that was prepared for the basic contract.

4.1.2 Sampling and Analysis Plan (SAP) and Quality Assurance Project Plan (QAPP)

The contractor will prepare a Draft and Final SAP/QAPP in accordance with the Guidance for

Quality Assurance Project Plans,, the Uniform Federal Policy for Quality Assurance Project Plans

(UFP-QAPP), the "Uniform Federal Policy for Implementing Environmental Quality Systems" and

the " Department of Defense Instruction: Environmental Quality Systems” The SAP will comprise a

Field Sampling Plan (FSP) and a Quality Assurance Project Plan (QAPP), at a minimum. The

FSAP will be submitted as an Appendix to the Removal Work Plan.

The contractor shall propose a methodology for selecting sampling locations, in coordination with

the RPM and the stakeholders to characterize and evaluate exposures to MC at the site(s).

Samples may be collected using anomaly avoidance techniques to ensure that intrusive sampling

of surface and subsurface soils does not result in exposure to explosive safety hazards or upon

completion of MEC removal activities, as appropriate to support the RI objectives. Samples shall

be analyzed in accordance with the most current approved methods consistent with the QAPP.

24

RPM Note: The following references for MC Sampling may be useful to the RPM.

a. Munitions Constituent (MC) Sampling Technical Update, USACE Military Munitions

Center of Expertise, March 2005

b. Sampling Studies at an Air Force Live-Fire Bombing Range Impact Area, USACE

ERDC, February 2006

c. Estimating Energetic Residue Loading on Military Artillery Ranges, Large Decision

Units, USACE ERDC, March 2005

d. Protocols for Collection of Surface Soil Samples at Military Training and Testing

Ranges for the Characterization of Energetic Munitions Constituents,USACE ERDC, July

2007

e.

USEPA SW 846 Test Methods for Evaluating Solid Waste, Physical/Chemical

Methods, Method 8330B Nitroaromatics, Nitramines and Nitrate Esters by High Performance

Liquid Chromatography and Method 8321A Solvent Extractable Nonvolatile Compounds by

High Performance Liquid Chromatography/Thermospray/Mass Spectrometry (HPLC/TS/MS)

or Ultraviolet (UV) Detection

f.

DoD EDQW Guide for Implementing EPA SW-846 Method 8330B

g. Implementation of Incremental Sampling (IS) of Soil for the Military Munitions

Response Program, USACE Interim Guidance 09-02, July 20, 2009.

The analytical laboratory should be identified in the proposal and must be identified in the FSAP

and hold all applicable state certifications to perform the analytical methods required. Laboratories

must also meet Navy IR QA Program requirements presented in the most current version of the

Navy Installation Chemical Data Quality Manual, SP-02056-ENV.

The contractor shall determine the position of all sample locations using Global Positioning System

(GPS) or other location method that will achieve a horizontal accuracy of [insert number] feet. The

contractor shall prepare a drawing and spreadsheet of the sample location information (name,

coordinates) and submit it as part of the MC Data Package with the RI Report. The same

information will also be submitted to NIRIS using the NEDD and automated data checker. . QA/QC

samples of sufficient matrix medium type and quantity must be collected.

The QAPP will outline the contractor’s Quality Control and Quality Assurance measures. The

duplicate QA and QC samples will be analyzed for the same parameters as the field samples. All

samples will be submitted to a Navy-accredited laboratory. All procedures for samples collected

and analyzed for MC shall be addressed and identified in the QAPP and FSAP.

RPM Note: If you plan on installing monitoring wells in a MRS, you will need to incorporate

anomaly avoidance measures. This is typically done by using a detector to find an area

clear of anomalies, pushing the drill to the depth of the detection limits, pulling out the drill

and placing the detector in to ensure the next depth is clear. This can be cumbersome, so

consider installing wells in areas that have no MEC history if possible. Sometimes moving

the location of the well can avoid potential MEC, without sacrificing the objectives of the

well location and sampling.

The USACE has a reference that can be useful for MC sampling titled USACOE MM CX

Technical Update for Munitions Constituents Sampling dated March, 2005. In addition, the

25

EPA’s SW 846 Method 8330B (November 2006 update to the original 8330) includes field

sampling techniques as well as analytical procedures for munitions constituents sampling

on ranges. EPA Method 8321 uses a mass spectrometer to positively identify the

compounds present.

RPMs will need to choose which method to use based on site-specific DQOs. It should be

noted that because EPA Method 8330B is relatively new, only a few commercial laboratories

have been approved by the Navy to perform this analytical method. If method 8330B is

chosen it is important to review the DoD Environmental Data Quality Workgroup Guide for

Implementing EPA SW-846 Method 8330B. Important considerations include involving a risk

assessor, and processing the entire field sample through the machine grinding process to

reduce error. RPMs should be aware that the grinding and subsequent extraction

procedure may overestimate the risk posed by the constituents by altering the sample’s

matrix conditions. Method 8330B uses a UV detector, which is not definitive, so a

confirmatory method (lc/ms is an option in 8330B or 8321) could also be used on a subset

of the samples to positively identify the constituents present. The RPM will have to

determine how to cost effectively manage the sampling and analysis costs. Also, the MR

portal has a summary on Energetic Constituent Sampling.

For Munitions Constituents below an explosive hazard, the RPM is required to develop a

UFP-SAP. The UFP QAPP Manual Guidance is implemented by NAVFAC through

completion of thirty seven separate worksheets that address specific elements of the UFP

QAPP guidance. Each of the worksheets references the applicable section of the UFP