USER GUIDE

For Installation Guide see reverse of book

THESE INSTRUCTIONS TO BE RETAINED BY USER

combination boilers

June 2022

UIN 223483 A05

2

User’s

THE BENCHMARK SERVICE INTERVAL RECORD MUST BE COMPLETED AFTER EACH SERVICE

Ideal Heating is a member of the Benchmark scheme and fully supports the aims of the

programme. Benchmark has been introduced to improve the standards of installation and

commissioning of central heating systems in the UK and to encourage the regular servicing of all

central heating systems to ensure safety and efciency.

All Gas Safe Register installers carry a Gas Safe Register ID card, and have a registration number. Both should be recorded in the

Benchmark Commissioning Checklist. You can check your installer by calling Gas Safe Register direct on 0800 4085500.

1. INTRODUCTION

This boiler is a combination boiler providing both central heating

and instantaneous domestic hot water. Featuring full sequence

automatic ignition and fan assisted combustion.

Due to the high efciency of the boiler, condensate is produced from

the ue gases and this is drained to a suitable disposal point through

a plastic waste pipe at the base of the boiler. A condensate ‘plume’

will also be visible at the ue terminal.

SAFETY

Current Gas Safety (Installation & Use) Regulations or

rules in force.

In your own interest, and that of safety, it is the law that this

boiler must be installed by a Gas Safe Registered Engineer, in

accordance with the above regulations.

In IE, the installation must be carried out by a Registered Gas Installer

(RGII) and installed in accordance with the current edition of I.S. 813

“Domestic Gas Installations”, the current Building Regulations and

reference should be made to the current ETCI rules for electrical

installation.

It is essential that the instructions in this booklet are strictly

followed, for safe and economical operation of the boiler.

ELECTRICITY SUPPLY

This appliance must be earthed.

Supply: 230 V ~ 50 Hz. The fusing should be 3A.

IMPORTANT NOTES

• This appliance must not be operated without the casing

correctly tted and forming an adequate seal.

• If the boiler is installed in a compartment then the compartment

MUST NOT be used for storage purposes.

•

If it is known or suspected that a fault exists on the boiler then

it MUST NOT BE USED until the fault has been corrected by

a Gas Safe Registered Engineer or in IE a Registered Gas

Installer (RGII).

• Under NO circumstances should any of the sealed components

on this appliance be used incorrectly or tampered with.

•

This appliance can be used by children 8 years and

above. Also persons with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge,

provided they have been given supervision or instruction

concerning use of the appliance in a safe way and

understand the hazards involved. Children shall not play

with the appliance. Cleaning and user maintenance shall

not be made by children without supervision.

CONTENTS

1. Introduction .............................................................. 2

Safety ......................................................................... 2

Electricity Supply ........................................................ 2

Important Notes .......................................................... 2

2. Boiler Operation ....................................................... 3

Controls Diagram........................................................ 3

To Start the Boiler ....................................................... 3

Operation Modes ........................................................ 3

Preheat Domestic Hot Water ...................................... 3

Control of Water Temperature .................................... 3

Efcient Heating System Operation............................ 4

Weather Compensation .............................................. 4

Boiler Frost Protection ................................................ 4

Boiler Restart .............................................................. 4

Mains Power Off ......................................................... 4

3. System Water Pressure ........................................... 4

4. Condensate Drain ..................................................... 4

5. General Information ................................................. 5

Boiler Pump ................................................................ 5

Minimum Clearances .................................................. 5

Escape of Gas ............................................................ 5

Cleaning ..................................................................... 5

Maintenance ............................................................... 5

6. Mechanical 24 Hour Timer ....................................... 5

7. Points for the Boiler User ........................................ 6

Troubleshooting .......................................................... 6

8. Normal Operation Display Codes ........................... 7

9. Fault Codes ............................................................... 8

3

User’s

TO START THE BOILER

Start the boiler as follows:

1. Check that the electricity supply to boiler is off.

2. Set the mode knob (C) to ‘BOILER OFF’.

3. Set the Domestic Hot Water temperature knob (A) and Central

Heating temperature knob (B) to ‘max’.

4. Ensure that all hot water taps are turned off.

5.

Switch on electricity to the boiler and check that all controls,

e.g. timer and room thermostat, are on.

6. Set the mode knob (C) to ‘ ’ (winter).

The boiler will commence ignition sequence, supplying heat to the

central heating, if required.

Note. In normal operation the boiler status display (D) will show codes:

00 Standby - no demand for heat.

CH - “80

†

” Central Heating being supplied

H - “60

†

”

Domestic hot water being supplied

P H - “60

†

” Domestic hot water preheat

F P - “10

†

”

Boiler frost protection-boiler will re if temperature is below 5ºC.

†

= temperature shown for example purposes only

During normal operation the burner on indicator (F) will remain

illuminated when the burner is lit.

Note: If the boiler fails to light after ve attempts the fault code

will be displayed (refer to Fault Code page).

OPERATION MODES

Winter Conditions -

(Central Heating and Domestic Hot Water required)

Set the mode knob (C) ‘ ’ (winter).

The boiler will re and supply heat to the radiators but will give

priority to domestic hot water on demand.

The domestic hot water preheat will operate with the

‘

preheat

’

button pressed so that the reheat indicator (G) is on.

Summer Conditions - (Domestic Hot Water only required)

Set the mode knob (C) to ‘

’ (summer).

Set the central heating demand on the external controls to OFF.

The domestic hot water preheat will operate with the

‘

preheat

’

button pressed so that the preheat indicator (E) is on.

Boiler Off

Set the mode knob (C) to ‘OFF’. The boiler mains power supply

must be left on to enable frost protection (see Frost Protection).

PREHEAT - DOMESTIC HOT WATER

The domestic hot water heat exchanger within the boiler can be

kept preheated to provide faster delivery of hot water at the tap.

This is achieved by pressing the ‘

preheat

’ button

(G)

so that

the

preheat indicator (E) is on

.

The boiler will operate periodically for a few seconds to maintain

the domestic hot water heat exchanger in a preheated condition.

The average time period between operation is 90 minutes. This

may vary considerably due to the surrounding ambient temperature

of the boiler. The boiler will operate whenever there is a demand

for domestic hot water.

If standard hot water delivery is satisfactory press the ‘

preheat

’

button (G) so that

the preheat indicator (E) is off

.

CONTROL OF WATER TEMPERATURE

Domestic Hot Water

The domestic hot water temperature is limited by the boiler

controls to a maximum temperature of 65

º

C, adjustable via the

domestic hot water temperature knob (A).

Approximate temperatures for domestic hot water:

Knob Setting Hot Water Temperature (approx.)

Minimum 40ºC

Maximum 65ºC

Due to system variations and seasonal temperature uctuations

domestic hot water ow rates/temperature rise will vary, requiring

adjustment at the tap : the lower the ow rate the higher the

temperature, and vice versa.

Central Heating

The boiler controls the central heating radiator temperature to a

maximum of 80

o

C, adjustable via the central heating temperature

knob (B).

Approximate temperatures for central heating:

Knob Setting

Central Heating Radiator Temperature (approx.)

Minimum 30ºC

Maximum 80ºC

For economy setting ‘

’ refer to Efcient Heating System

Operation.

2. BOILER OPERATION

continued..........

Legend

A. Domestic Hot Water Temperature Knob

B. Central Heating Temperature Knob

C. Mode Knob

D. Boiler Status Display

E. Preheat Indicator

F. Burner ‘on’ Indicator

G. Preheat On Off button

H. Restart button

J. Central Heating Economy Setting

K. Pressure Gauge

L. Timer

88

A

L

K BDFE G H CJ

4

User’s

3. SYSTEM WATER PRESSURE

The system pressure gauge (K - see

page 3) indicates the central heating

system pressure. If the pressure is seen

to fall below the original installation

pressure of 1-2 bar over a period of

time

and continue to fall then a water

leak may

be indicated. In this event re-

pressurise the system. If unable to do so or if the pressure

continues to drop a Gas Safe Registered Engineer or in IE a

Registered Gas Installer (RGII) should be consulted.

THE BOILER WILL NOT OPERATE IF THE PRESSURE

HAS REDUCED TO LESS THAN 0.3 BAR UNDER THIS

CONDITION.

4. CONDENSATE DRAIN

This appliance is tted with a siphonic condensate trap

system that reduces the risk of the appliance condensate

from freezing. However should the condensate pipe to this

appliance freeze, please follow these instructions:

a. If you do not feel competent to carry out the defrosting

instructions below please call your local Gas Safe

Registered installer for assistance.

b.

If you do feel competent to carry out the following instructions

please do so with care when handling hot utensils. Do not

attempt to thaw pipework above ground level.

If this appliance develops a blockage in its condensate pipe,

its condensate will build up to a point where it will make a

gurgling noise prior to locking out an “L2” fault code. If the

appliance is restarted it will make a gurgling noise prior to it

locking out on a failed ignition “L2” code.

To unblock a frozen condensate pipe;

1. Follow the routing of the plastic pipe from its exit point on

the appliance, through its route to its termination point.

Locate the frozen blockage. It is likely that the pipe is

frozen at the most exposed point external to the building

or where there is some obstruction to ow. This could be

at the open end of the pipe, at a bend or elbow, or where

there is a dip in the pipe in which condensate can collect.

The location of the blockage should be identied as

closely as possible before taking further action.

2. Apply a hot water bottle, microwaveable heat pack or a

warm damp cloth to the frozen blockage area. Several

applications may have to be made before it fully defrosts.

Warm water can also be poured onto the pipe from a

watering can or similar. DO NOT use boiling water.

3. Caution when using warm water as this may freeze and

cause other localised hazards.

4.

Once the blockage is removed and the condensate can ow

freely, restart the appliance. (Refer to “To Start the Boiler”)

5. If the appliance fails to ignite, call your Gas Safe

Registered engineer.

Preventative solutions

During cold weather, set the central heating temperature knob

(B) to maximum, (Must return to original setting once cold

spell is over).

Place the heating on continuous and turn the room

thermostat down to 15ºC overnight or when unoccupied.

(Return to normal after cold spell).

EFFICIENT HEATING SYSTEM OPERATION

The boiler is a high efciency, condensing appliance which will

automatically adjust its output to match the demand for heat.

Therefore gas consumption is reduced as the heat demand is

reduced.

The boiler condenses water from the ue gases when operating

most efciently. To operate your boiler efciently (using less gas)

turn the central heating temperature knob (B) to the ‘

e ‘ position

or lower. In winter periods it may be necessary to turn the knob

towards the ‘max’ position to meet heating requirements. This will

depend on the house and radiators used.

Reducing the room thermostat setting by 1ºC can reduce gas

consumption by up to 10%.

WEATHER COMPENSATION

When the Weather Compensation option is tted to the system then

the central heating temperature knob (B) becomes a method of

controlling room temperature. Turn the knob clockwise to increase

room temperature and anti-clockwise to decrease room temperature.

Once the desired setting has been achieved, leave the knob in this

position and the system will automatically achieve the desired room

temperature for all outside weather conditions.

BOILER FROST PROTECTION

The boiler is tted with frost protection that operates in all modes,

provided the power supply to the boiler is always turned on. If

the water in the boiler falls below 5ºC, the frost protection will

activate and run the boiler to avoid freezing. The process does not

guarantee that all other parts of the system will be protected.

If a system frost thermostat has been installed, the boiler must be

set in winter mode, ‘

’, for the system frost protection to run.

If no system frost protection is provided and frost is likely during a

short absence from home it is recommended to leave the system

heating controls or built in programmer (if tted) switched on and

run at a reduced temperature setting. For longer periods, the entire

system should be drained.

BOILER RESTART

To restart the boiler, when directed in the listed fault codes (see

section 9) press the restart button (H). The boiler will repeat its

ignition sequence. If the boiler still fails to start consult a Gas Safe

Registered Engineer or an IE Registered Gas Installer (RGII).

MAINS POWER OFF

To remove all power to the boiler the mains power switch must be

turned off.

5

User’s

5. GENERAL INFORMATION

BOILER PUMP

The boiler pump will operate briey as a self-check once every 24

hours, regardless of system demand.

MINIMUM CLEARANCES

Clearance of 165mm (6

1

/2”) above, 100mm (4”) below, 2.5mm (

1

/8”)

at the sides and 450mm (17

3

/4”) at the front of the boiler casing

must be allowed for servicing.

Bottom Clearance

Bottom clearance after installation can be reduced to 5mm

This must be obtained with an easily removable panel, to provide

the 100mm clearance required for servicing.

ESCAPE OF GAS

Should a gas leak or fault be suspected contact the National Gas

Emergency Service without delay. Telephone 0800 111 999.

Ensure that;

- All naked ames are extinguished

- Do not operate electrical switches

- Open all windows and doors

CLEANING

For normal cleaning simply dust with a dry cloth. To remove stubborn

marks and stains, wipe with a damp cloth and nish off with a dry

cloth. DO NOT use abrasive cleaning materials.

MAINTENANCE

The appliance should be serviced at least once a year by a Gas

Safe Registered Engineer or in IE a Registered Gas Installer

(RGII).

6. MECHANICAL 24 HOUR TIMER

Permanently o Permanently on

Time Indicator

Align current time to arrow

Timer Control

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

O

N

P

e

r

i

o

d

O

N

P

e

r

i

o

d

Operating Mode Indicator

SETTING UP

The outer dial should be set to the current time. Rotate the dial

slowly in a clockwise direction, until the correct hour is aligned

with the arrow printed on the dial.

Note that the outer dial is printed with the 24hr clock e.g. 8.00am

= 8 on the dial, 8.00pm = 20 on the dial.

Do not attempt to rotate the dial in an anti-clockwise

direction.

PROGRAMMING SWITCHING TIMES

Set tappets to outer edge for ON periods and set tappets to inner

edge for OFF periods.

The example shown has been set with 2 on periods.

ON at 9.00am. OFF at 1.00pm. (13 hours)

ON at 6.00pm. (18 hours) OFF at 10.00pm (22 hours)

Manual Switch Operation

To set the timer for timed operation move the switch to the

“TIMED” position.

To set the timer to be continuously on, move the switch to the

“MANUAL ON” position.

To set the timer to be continuously off, move the switch to the

“MANUAL OFF” position.

Note. If boiler does not light when in “timed on” or “manual on”

position, increase temperature on room stat.

6

User’s

7. POINTS FOR THE BOILER USER

Note. In line with our current warranty policy we would ask that you check through the following guide to identify any

problems external to the boiler prior to requesting a service engineers visit. Should the problem be found to be other

than with the appliance we reserve the right to levy a charge for the visit, or for any pre-arranged visit where access is

not gained by the engineer.

TROUBLESHOOTING

YES

YES

NO HOT WATER

Check the mains power is turned

on and ensure mode knob (C) is

in the summer or winter position

Is water coming out of the hot

water tap when turned on?

NO CENTRAL HEATING

Check the mains power is turned

on and ensure mode knob (C) is

in the winter position

Does the boiler operate and

provide central heating?

Check the time settings on the

timer are as you require and

adjust if necessary

Check the timer is in an “ON”

position and the room thermostat

is turned up

NO HOT WATER OR

CENTRAL HEATING

Check the mains power is turned

on and ensure mode knob (C) is

in the winter position

See boiler “Operation Modes”

and “Fault Codes” section

Does the boiler have a display

showing on the front control

panel?

See boiler “Fault Codes”

section. If ‘00’ is displayed then

contact Ideal Customer Services

Helpline if your appliance is

under warranty or a Gas Safe

Registered Engineer, in IE a

Registered Gas Installer (RGII),

if out of warranty

YES

NO

Contact a Gas Safe Registered

Engineer or in IE a Registered

Gas Installer (RGII)

NO

See boiler “Operation Modes”

and “Fault Codes” section. If

“00” is displayed then contact a

Gas Safe Registered Engineer

or in IE a Registered Gas

Installer (RGII)

NO

Contact a Gas Safe Registered

Engineer or in IE a Registered

Gas Installer (RGII)

7

User’s

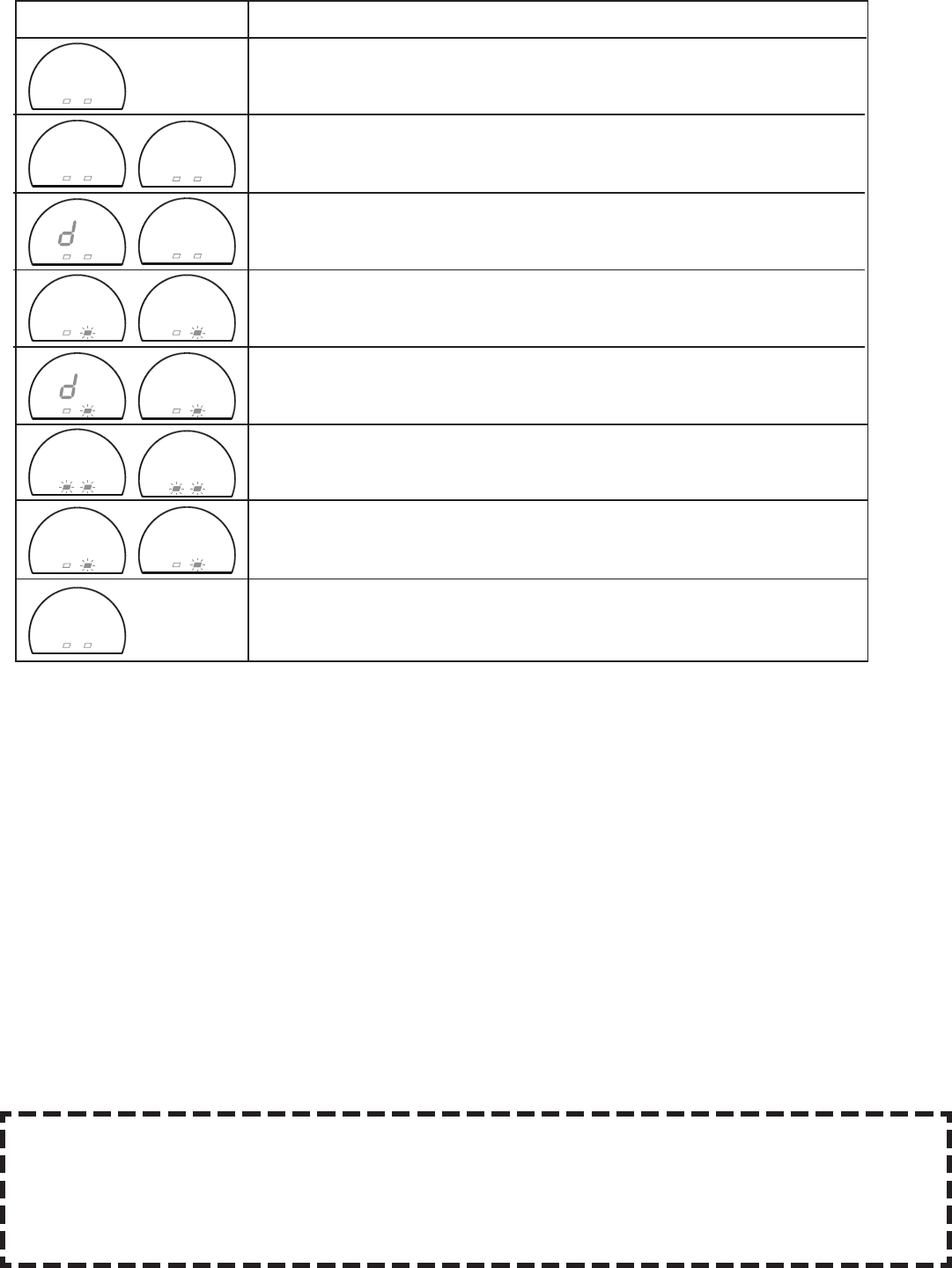

DISPLAY CODE ON BOILER

DESCRIPTION

The boiler is in standby operation awaiting either a central heating call or hot water demand.

The boiler has a call for central heating but the appliance has reached the desired

temperature set on the boiler.

The boiler has a call for hot water but the appliance has reached the desired temperature set on

the boiler.

The boiler is operating in central heating mode.

The boiler is operating in domestic hot water preheat mode.

The boiler is operating in domestic hot water mode.

The boiler is operating in frost protection.

8. NORMAL OPERATION DISPLAY CODES

FOR ANY QUERIES PLEASE RING THE

ATLANTIC

COMBI CONSUMER HELPLINE : 01482 498660

NOTE. BOILER RESTART PROCEDURE -

To restart the boiler press the restart button. The boiler will repeat the ignition sequence if a heat demand is

present.

The boiler mode knob (C) is in the off position, rotate fully clockwise for hot water and central

heating operation.

00

80

80

60

60

60

1 0

CH

CH

H

FP

--

PH

H

†

†

†

†

†

†

† = temperature shown for example purposes only.

8

User’s

5 Boiler Resets in 15 minutes

Negative Differential

Flow/Return Thermistor

1. Turn electrical supply to boiler off and on.

2. If the boiler fails to operate please contact Ideal (if under warranty) or alternatively

a Gas Safe Registered Engineer if outside of the warranty period. In IE contact a

Registered Gas Installer (RGII).

If the boiler fails to operate then please contact Ideal (if under warranty) or alternatively

a Gas Safe Registered Engineer if outside of the warranty period. In IE contact a

Registered Gas Installer (RGII).

False Flame Lockout

Restart the appliance - if the boiler fails to operate then please contact Ideal (if under

warranty) or alternatively a Gas Safe Registered Engineer if outside of the warranty

period. In IE contact a Registered Gas Installer (RGII).

DISPLAY CODE ON BOILER

DESCRIPTION

Low Water Pressure

ACTION

Check system water pressure is between 1 & 1.5bar on the system pressure

gauge. To

re-pressurise the system see Section 3. If the boiler still fails to operate then please contact

Ideal (if under

warranty) or alternatively a Gas Safe Registered Engineer if outside of the

warranty period. In IE contact a Registered Gas Installer (RGII).

Check system water pressure is between 1 & 1.5bar on the system pressure

gauge.

To re-pressurise the system see Section 3. If the boiler fails to operate then please contact

Ideal (if under

warranty) or alternatively a Gas Safe Registered Engineer if outside of the

warranty period. In IE contact a Registered Gas Installer (RGII).

9. FAULT CODES

Flow Temperature Overheat

or No Water Flow

Flow/Return Differential >

50°C

If the boiler fails to operate then please contact Ideal (if under warranty) or alternatively

a Gas Safe Registered Engineer if outside of the warranty period. In IE contact a

Registered Gas Installer (RGII).

Rotate all knobs fully clockwise, turn boiler power off and on then press restart.

Diverter Valve in mid-position

for service

Flame Loss

Ignition Lockout

1. Check other gas appliances in the house are working to conrm a supply is present in

the property.

2

. If other appliances do not work or there are no other appliances, check the gas supply

is on at the meter and/or pre payment meter has credit. If the boiler fails to operate then

please contact Ideal (if under warranty) or alternatively a Gas Safe Registered Engineer

if outside of the warranty period. In IE contact a Registered Gas Installer (RGII).

1. Check condensate Pipe for blockages (refer to Section 4)

2. Check other gas appliances in the house are working to conrm a supply is present in

the property.

3. If other appliances do not work or there are no other appliances, check the gas supply

is on at the meter and/or pre payment meter has credit. If the boiler fails to operate then

please contact Ideal (if under warranty) or alternatively a Gas Safe Registered Engineer

if outside of the warranty period. In IE contact a Registered Gas Installer (RGII).

Fan Fault

Restart the appliance - if the boiler fails to operate then please contact Ideal (if under

warranty) or alternatively a Gas Safe Registered Engineer if outside of the warranty

period. In IE contact a Registered Gas Installer (RGII).

Flow Thermistor

Restart the appliance - if the boiler fails to operate then please contact Ideal (if under

warranty) or alternatively a Gas Safe Registered Engineer if outside of the warranty

period. In IE contact a Registered Gas Installer (RGII).

Return Thermistor

Restart the appliance - if the boiler fails to operate then please contact Ideal (if under

warranty) or alternatively a Gas Safe Registered Engineer if outside of the warranty

period. In IE contact a Registered Gas Installer (RGII).

Outside Sensor Failure

Restart the appliance - if the boiler fails to operate then please contact Ideal (if under

warranty) or alternatively a Gas Safe Registered Engineer if outside of the warranty

period. In IE contact a Registered Gas Installer (RGII).

Low Mains Voltage

Contact a qualied electrician or your electricity provider.

Uncongured PCB

Uncongured/faulty PCB or gas valve short circuit. Please contact Ideal (if under

warranty) or alternatively a Gas Safe Registered Engineer if outside of the warranty

period. In IE contact a Registered Gas Installer (RGII).

F1

F2

F3

F4 L4

F5 L5

F6

F7

F9 L9

L1

L2

L6

LC

FA

FU

U

No primary water ow

Pump dry run

Pump rotor blocked

Check system water pressure is between 1 & 1.5bar on the system pressure

gauge. To

re-pressurise the system see Section 3. If the boiler still fails to operate then please contact

Ideal (if under

warranty) or alternatively a Gas Safe Registered Engineer if outside of the

warranty period. In IE contact a Registered Gas Installer (RGII).

Check system water pressure is between 1 & 1.5bar on the system pressure

gauge. To

re-pressurise the system see Section 3. If the boiler still fails to operate then please contact

Ideal (if under

warranty) or alternatively a Gas Safe Registered Engineer if outside of the

warranty period. In IE contact a Registered Gas Installer (RGII).

If the boiler fails to operate then please contact Ideal (if under warranty) or alternatively

a Gas Safe Registered Engineer if outside of the warranty period. In IE contact a

Registered Gas Installer (RGII).

FH

FL

FP