Sentry II

TM

Made in USA

An FKI Industries Company

700 West Bridge Street

Owatonna, MN 55060

www.truth.com

Form 90063 R2

Window or Light Skylight

Motorization System

Installation Instructions

Did you find what you’re looking for? The Truth Hardware Web site is a great resource for

the latest product and installation information. It’s available at www.truth.com

2

Danger: To help prevent severe personal injury or death:

• Read and understand instructions completely before beginning

installation.

• Wiring must be installed by a qualified electrician according to

local and National Electrical Codes (N.E.C.)

• Disconnect main power before beginning installation! Verify

that power is OFF at the main breaker or fuse panel by testing

with a voltage meter that you know is working correctly.

• Connect power only after motor connections and settings are

verified.

• This equipment does not provide a method to shut off power,

and should be connected to a dedicated breaker or fused

power circuit capable of providing 1 amp at 120 VAC of power

per window unit.

• The screen interlock MUST be correctly installed and is a

required part of the power window system. It is intended to

help prevent injury that could result from reaching into the

window area during operation. The correct installation of the

screen interlock is the responsibility of the installer. (The

screen interlock is not required on windows and skylights

installed more than 8 feet above the floor.)

• Do not allow children to operate the wall push buttons or

remote control transmitter(s).

Additional Safety Guidelines

• When connecting the Sentry II system to accessories, read the

installation instructions supplied with each accessory before

beginning installation.

• The Sentry II system must not be used on windows intended

to meet egress codes.

• The Sentry II system is intended for indoor use only, with

screens in place.

• Save ALL instructions. Additional copies can be downloaded

off of our web site at: truth.com\technicalsupport

• Installer – please be sure to give ALL instructions to the

homeowner once installation is complete.

Did you find what you’re looking for? The Truth Hardware Web site is a great resource for

the latest product and installation information. It’s available at www.truth.com

3

[

What you should know before starting....4

Parts List ....................................................5

Planning......................................................6

Inspect Windows........................................7

Battery Backup ..........................................8

Motor Installation ......................................9

Controller Installation ...............................14

Main Wiring Diagram.................................17

Normal Operation.......................................20

Rain Sensor................................................21

HPI...............................................................22

Power Blind Control ..................................23

Common Problems....................................24

System Reset ............................................26

Service .......................................................27

Status Light Code......................................28

Control Box Cut-Out Template .................29

Regulatory Compliance.............................30

Getting Started

Set Up

Installation

Troubleshooting

Table of Contents

Operation

Accessories

Additional Info

Preparation

Did you find what you’re looking for? The Truth Hardware Web site is a great resource for

the latest product and installation information. It’s available at www.truth.com

4

Supply Voltage Note: The supply voltage range for the Sentry II power window

system is very flexible to accommodate supply voltages available from many

different countries. The input (supply) voltage range is 90 to 264 VAC at a

frequency range of 47 to 440 Hz. For practical purposes, the supply voltage

referenced in this document is 120 volts at 60 Hz commonly used in the United

States.

Operating Environment: The control unit must be located in a dry environment

which includes protection from condensation. The operating temperature range

must be maintained between 140º F (60º C) to -5º F (-20º C).

Be sure the motor system will fit in your application: The Sentry power

window system is intended to fit onto casement, awning and skylight hardware

manufactured by Truth Hardware only. In many cases you will be able to identify

our hardware by our logo ( ) somewhere on the hardware. When in doubt, the

best way to tell is if the spline adaptor fits onto the operator stem in place of the

crank handle – see Motor Installation step 2 .

The Sentry II power window will not work in the following applications:

• Fitted to any type of jalousie window

• Fitted to any type of door

• Fitted to any type of cable controlled window system - Such as those

manufactured by Clearline or Ultra-Flex

• Fitted to any type of in-swing window

• Fitted to any type of manual skylight hardware manufactured by Velux or

Roto

Any use of the Sentry II power window system not approved by Truth

Hardware is at the user’s own risk.

Be sure the motor system is compatible with your application: It is

important to understand that the design parameters of the Sentry II power

window system are predicated on a properly functioning manual window system.

This includes the rotary operators and

hinges installed on the window. It is the

responsibility of the window manufacturer and/or the window specifier to insure

the window size and weight fall within the specifications of the manual hardware

system installed on the window. If the window size and/or weight fall outside of

the hardware specifications, the motor system may not function properly. If the

window carries an AAMA (American Architectural Manufacturers Association)

label chances are the window system meets all hardware requirements.

However, if the window does not carry an AAMA label you may want to contact

the window manufacturer to verify the windows have been manufacturer within

the hardware manufacturer’s specifications - especially if the window size is

unusually large and/or of unusual proportions.

What You Should Know Before Starting

Did you find what you’re looking for? The Truth Hardware Web site is a great resource for

the latest product and installation information. It’s available at www.truth.com

5

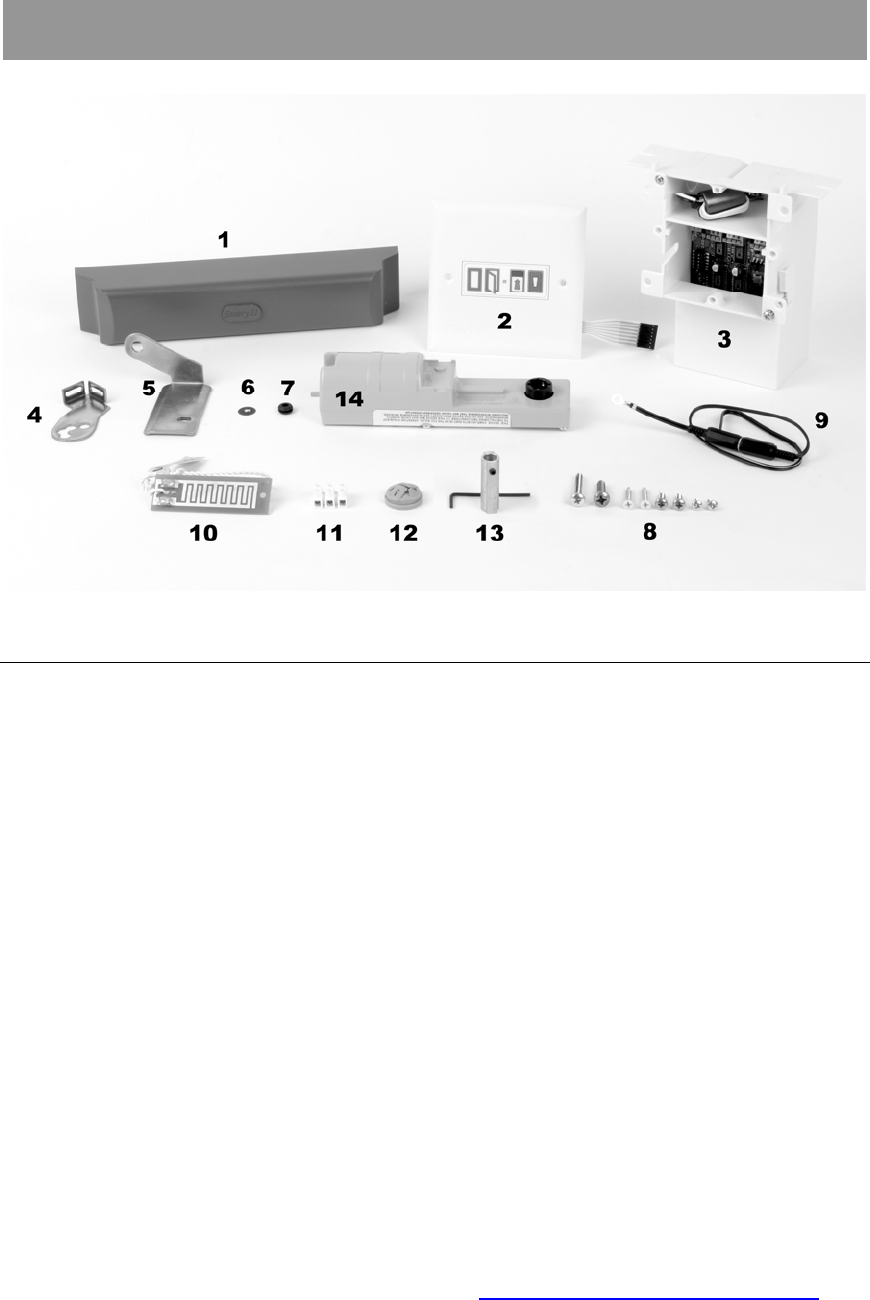

Parts list Part number

1. Motor Cover 12490.XX (not part of kit)

2. Control unit cover plate 12488

3. Wall mounted control unit 12592

4. Mounting bracket – Window *

5. Mounting bracket – Skylight ** Parts 4 thru 13 are in

6. Push on fastener hardware pack 12492

7. Isolation grommet

8. Screws

9. Screen interlock

10. Rain sensor Replacement part #22123

11. Terminal block

12. Strain relief

13. Spline adapter and wrench

14. Motor unit 12547.00.0001

Installation instructions (not pictured) 90063

* Window bracket may look slightly different.

** Skylight bracket is not included with all kits.

XX Indicates a color selection

Note:

• No wire is included. See wiring diagram on page 17 for wire requirements.

• To replace broken parts, please go to www.truth.com/technicalsupport

Getting Started

Did you find what you’re looking for? The Truth Hardware Web site is a great resource for

the latest product and installation information. It’s available at www.truth.com

6

Planning

Important: If you are not the homeowner, it is important to contact the

homeowner and discuss how they want to control a group of windows and/or

skylights. It may be very difficult to change the installation to meet the

homeowner’s desires once installation is complete.

Please consider:

• If installing more than one power window system, each motorized window

must

have its own control unit. If there are multiple windows and/or

skylights installed and it is desired to have a single control point for all

windows and skylights, the wireless RF remote control will give you this

option. Since the remote control uses RF communication technology it is

not restricted to line-of site limitations. (See remote control operating

instructions for more information - also available at

truth.com/technicalsupport)

• The control unit will give convenient wall mounted control only for the

window connected to it. If the wall mounted control is not intended to be

the primary means of control you may want to consider mounting it in a

remote, out-of-the-way location.

• All Sentry II control units are Remote Control enabled. This allows you the

convenience of adding an optional remote control at any time.

• If you are installing the motor system onto a window that has manual locks

be sure the locks are unlocked manually before attempting to open.

Power sash locks are an available option for some windows.

• The Sentry II power window system does not have manual override in

case of a power outage. If it is important to be able to close the windows

without power, consider installing a battery back-up system.

• There are a number of other control options available:

o Remote Control Has Built-in Thermostat - For those applications

where it is desirable to open and close your windows or skylights

based on temperature, please be aware that the optional remote

control has a built-in thermostat. Just set the temperature and

place the remote in the area where you want the temperature

controlled.

o Rain Sensor - A rain sensor comes standard with each unit. If you

choose to install the rain sensor option, each control unit needs a

separate rain sensor. Consult main wiring diagram for wiring

requirements if used. List max dist.

o Power Sash Locks - The optional power sash locks require

additional wires to be run from the control unit to the window.

Consult main wiring diagram for wiring requirements if used.

Did you find what you’re looking for? The Truth Hardware Web site is a great resource for

the latest product and installation information. It’s available at www.truth.com

7

o Power mini blinds - The Sentry II control unit is capable of

controlling power mini blinds (supplied by others) in addition to the

window motor and sash locks. See page 23 for additional

information. Consult main wiring diagram for wiring requirements if

used.

o Window status feedback - The Sentry II control unit is capable of

providing window position feedback (open or closed). See page 23

for additional information. Consult main wiring diagram for wiring

requirements if used.

o Integrated control with other control systems - The Sentry II

power window system can be integrated with other automated

control systems. Some examples are home automation systems,

thermostats and security systems. See page 22 for additional

information. Consult main wiring diagram for wiring requirements if

used.

• Each control unit requires 1 amp of power at 120 VAC.

• Plan your wiring routes carefully. Low voltage wires must not be run

parallel to high voltage wires. Be sure to use shielded, twisted pair wiring

in electrically noisy environments.

Set Up

Inspect Windows

The windows and/or skylights must operate correctly and smoothly. Lubrication

or cleaning of hardware may be required. This motor system will not operate

correctly if the manual hardware is not functioning properly.

Important Skylight Information:

• When installing the Sentry II motor on a skylight,

the skylight lid must weigh less than 40 lbs. at the

chain. A hand crank should be used to verify the

skylight operates smoothly.

• When installing on a skylight, the motor system will

only fit the angle drive model manufactured by

Truth Hardware shown in step 3. Verify the

skylight operator you have looks like the one

shown in step 3.

Skylight lid must

weigh less than

40lb (18 kg) at the

chain

Did you find what you’re looking for? The Truth Hardware Web site is a great resource for

the latest product and installation information. It’s available at www.truth.com

8

Battery Backup

Battery backup should be used to supply emergency power when operation of

the power window system must be maintained in the event of a power outage.

(Please note: A battery back-up is not required to provide memory back-up for

the Sentry II system.)

Truth recommends the use of a UPS (uninterruptible power supply) as a battery

backup. They are widely available through a variety of retail and commercial

outlets and are primarily used to supply emergency backup for computer

equipment. (Truth Hardware is not a supplier of battery back-up systems.)

To determine the proper VA rating for a UPS, take 50 watts and multiply by the

number of windows and/or skylights to be backed up by a given UPS. Below is a

list of the manufacturers who produce uninterruptible power supplies which we

have approved as compatible with our power window systems.

Powerware

Forum III

8609 Six Forks Road

Raleigh, NC 27615

(800) 554-3448

(919) 872-3020

www.powerware.com

American Power Conversion

132 Fairgrounds Road

West Kingston, RI 02892

(800) 788-2208

(401) 789-5735

www.apcc.com

Tripp Lite

1111 West 35th Street

Chicago, IL 60609

(773) 869-1111

www.tripplite.com

Minuteman (brand)

1455 LeMay Drive

Carrollton, TX 75007

(800) 238-7272

(972) 446-7363

www.minuteman-ups.com

Did you find what you’re looking for? The Truth Hardware Web site is a great resource for

the latest product and installation information. It’s available at www.truth.com

9

Installation

Up

Motor Installation

Note: Window operators are usually mounted to the bottom sill of the window.

Occasionally the operator will be mounted on the side jamb of an awning or

casement window and also occasionally to the head of a hopper window. These

are all acceptable applications provided the window opens and closes smoothly

throughout its full range of motion. Be sure the motor system is mounted

securely to the window in these applications.

1. Test hand crank

a. Determine the direction of hand crank rotation to open the window as

either Clockwise or Counter Clockwise (when facing the window operator).

b. Circle the direction to OPEN below. (This information will be needed for

proper system setup in Step 5.):

Note: The window or skylight can be in any position while installing the Sentry II

motor. However, leaving the window or skylight partially open is helpful in testing

system operation. When power is supplied to the motor for the first time, the

control system is programmed to close the window. A closing window upon

power-up will therefore confirm that the motor is receiving power and wiring

polarity is correct. If the window is closed during motor installation, a short

noticeable hum will confirm that the window is receiving power.

Did you find what you’re looking for? The Truth Hardware Web site is a great resource for

the latest product and installation information. It’s available at www.truth.com

10

2. Install adapter

Before installing the spline adapter determine how the adapter should be applied

to the type of window operator that you have.

If your window operator is similar to the picture shown below (some operators

may have the worm on the other side of the operator case) please switch the set

screw to the hole at the opposite end of the adaptor before installing on the

operator shaft. For all other operators, apply the adapter as it was shipped to

you.

If the operator looks

similar to the one

shown on the left

please move the

set screw from the

hole that it was

installed in for

shipping to the

open hole at the

opposite end of the

adaptor

After installing the spline adapter (B) onto operator

shaft, tighten set screw with wrench (A).

NOTE: Be sure the set screw is fully seated into the

operator shaft groove.

3. Choose wire location

Plan wire exit location on window for

• Operator motor

See figure 3a below for casement and awning windows and Figure 3b for

skylights

Note: Be sure the window width will accommodate the motor width. See

Fig.s 3c & 3d below for finished dimensions.

• Power sash lock (if used)

Consult power sash lock installation instructions

• Power mini blinds (if used)

Consult power mini blind installation instructions

A

Did you find what you’re looking for? The Truth Hardware Web site is a great resource for

the latest product and installation information. It’s available at www.truth.com

11

Figure 3a

Note: The placement information above

are guidelines only. In some cases it is

better to do a trial fit of the motor onto

the operator. Hold the motor square and

check both sides while looking for

interference between the motor housing

and operator housing.

Figure 3b

Figure 3c

Finished dimensions of motor system applied to a casement or awning window.

Figure 3d

Finished dimensions of the WLS motor system applied to a skylight window.

Did you find what you’re looking for? The Truth Hardware Web site is a great resource for

the latest product and installation information. It’s available at www.truth.com

12

4. Mount the motor

a. Slide motor over spline adapter (B).

b. Insert the isolation grommet (D) into the mounting bracket where it

best lines up with the motor mount post.

Note: If a number of mounting positions are provided by the bracket,

use the one which provides the best alignment with the window frame.

c. Secure motor with bracket (C).

Note: In window applications two screws should be used when

mounting the bracket (C) to wood or plastic window frames.

d. Slide the push-on fastener (E) over the motor post to secure the

motor to the bracket and window casing.

Warning: The push-on fastener is required for safety. Failure to install

the fastener (E) can cause the motor to become detached and fall from

window.

Window Mount

Sheet metal screws: (2) #8 x 5/8” Ph PH

Skylight Mount

Machine screw : (1) #12-24 x 1” Ph PH

5. Align and tighten collar

Align motor to window and tighten

set screw in black plastic alignment

collar (F) with wench (A).

Warning: Do not over tighten. Damage

will occur to alignment collar if it is

tightened excessively.

A

B

B

Did you find what you’re looking for? The Truth Hardware Web site is a great resource for

the latest product and installation information. It’s available at www.truth.com

13

6. Install screen interlock!

Install screen interlock (G) to the

face of the screen frame as shown

using the supplied pan head

screw (H). Refer to Main Wiring

diagram for connection

information.

WARNING: The screen interlock

must be installed on windows or

skylights less than 8 ft from the floor.

It is intended to prevent personal

injury and/or window damage during

operation

Self threading machine screw: #6-32 x 3/8” Ph PH

7. Secure wires and *install cover

a. Connect motor wires per wire

diagram (see page 17) and

secure with tape.

b. Install the motor cover using

the 6X3/8 PH screw (I) found

under cover button (J).

* WARNING: Use of a longer screw ()

will damage the motor and void the

warranty Use only the screw provided

for the motor cover (No. 6-32 X 3/8

Phillips pan head machine screw).

J*

Did you find what you’re looking for? The Truth Hardware Web site is a great resource for

the latest product and installation information. It’s available at www.truth.com

14

Controller Installation

1. Prepare wall for control unit

Note: A control unit is required for each motorized window. Connecting two

or more window motors to one control unit will overload and damage the control

unit and void the warranty. Multiple windows can be controlled from a single

control point via the optional RF remote control.

Important: The control unit is supplied with a protective cardboard shield to

protect the delicate control circuits from construction debris during the “rough-in”

building phase. Depending on the severity of construction debris expected at the

construction site, additional shielding may be required. Sealing the unit with duct

tape or some other means until the final wiring phase may be required.

If the install location already has a finished wall with unexposed studs, jump

ahead to page 15 and follow steps for “Finished Wall.”

Open Wall: Step 1

Locate the desired mounting

location for the wall control unit.

Mount control box onto the selected

wall stud with screws (not included)

at the desired height. Using the

template provided on page 29, mark

and cut the prescribed hole in wall

board for the intended application.

Open Wall: Step 2

Route and install wires - Route low

voltage wires from motor location

(including any accessory wires, such

as rain sensor, power blind, etc...) into

control switch opening. (See main

wiring diagram on page 17 for

complete wiring specifications.) Route

appropriate high voltage wire and

select an inlet on control box which

works with the selected orientation.

Remove knock-out and install strain

relief provided. Pull 120 VAC wiring

into control box through strain relief.

Skip “Finished Wall” steps 1 and 2.

Advance to page 16.

Break off

tabs (4)

Strain

Relief

Did you find what you’re looking for? The Truth Hardware Web site is a great resource for

the latest product and installation information. It’s available at www.truth.com

15

Finished Wall: Step 1

Locate the desired mounting location

for the wall control unit. Verify the

location of interior wall studs before

selecting the mounting orientation of

control box.

Using the template on page 29 of this

instruction booklet, mark and cut wall

opening. (Cutout size is 3 7/8 inches

Wide X 4 1/8 inches High) Note that a

portion of the wall box is hidden inside

the wall cavity, and that the box and wall

plate can be mounted in any direction

required.

Finished Wall: Step 2

Install Control Box

a. When installing the box after

the wall is finished the

mounting wings should be cut

off and discarded.

b. Insert control box into wall

opening.

c. Secure box to wall by

tightening clamp screws.

The wall clamps engage the wall

automatically as the screws are

tightened.

d. Route low voltage wires from

motor location (including any

accessory wires, such as rain

sensor, power blind, etc...) into

control switch opening.

See main wiring diagram on page

17 for complete wiring

specifications. Route appropriate

high voltage wire and select an

inlet on control box which works

with the selected orientation.

Remove knock-out and install

strain relief provided. Pull 120

VAC wiring into control box

through strain relief.

Clamp screws

Cut Off

Mounting

Wings

High

Voltage

Wires

Wall Box

Installed.

Use template located on page 29 to mark

cutout location and cut as required.

Orientation can be rotated if desired

Low

Voltage

Wires

Did you find what you’re looking for? The Truth Hardware Web site is a great resource for

the latest product and installation information. It’s available at www.truth.com

16

Danger: Power supplied to high voltage (120 VAC) wiring should be

disconnected at main breaker panel or through other means. This motor control

will need 1 amp of current at 120 VAC.

Note:

• Installation must meet local and national electrical codes.

• Refer to main wiring diagram for wire size and type requirements.

• Plan your wiring routes carefully. Low voltage wires must not be run parallel to high

voltage wires.

• Be sure to use shielded, twisted pair wiring in electrically noisy environments.

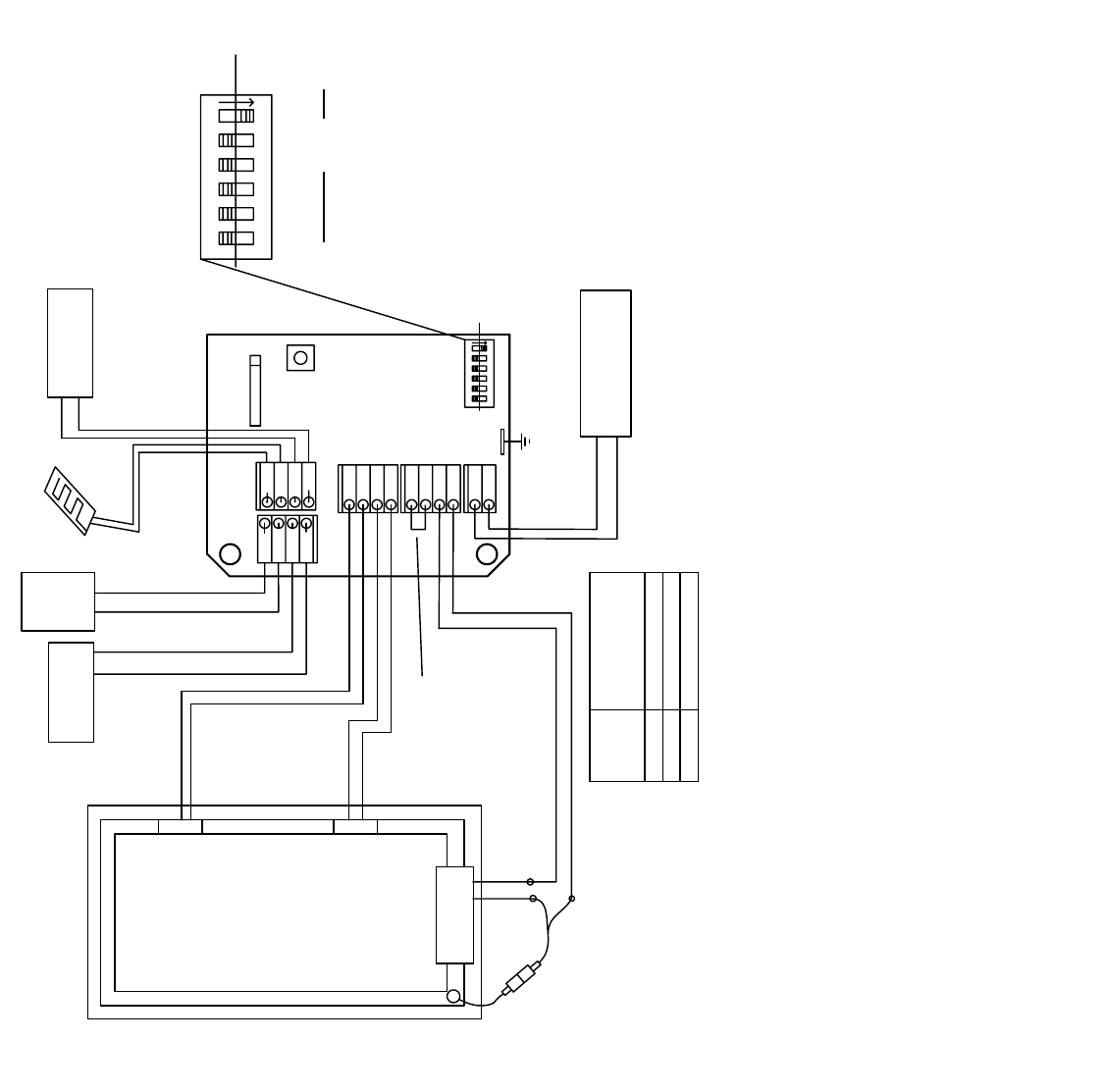

4. Connect Wires per wire diagram

Remove protective cardboard shield. Connect low voltage wires for operator

motor and all accessories to the control unit as diagramed on the main wiring

diagram (page 17). See terminal blocks 1 thru 5. (Do not apply power until step

7!)

Note:

1. Terminal blocks are rated for 16 to 20 gauge solid core wire. If wire runs are such

that wire sizes exceed 16 gauge, wire must be spliced down to a 16 to 20 gauge wire

before connection to terminal blocks. Keep reduced wire size length to a minimum

length. Use solid core wire only for connection to the control unit! Do not use

stranded wire.

2. Install and connect optional power sash locks at this time if used. Consult installation

instructions supplied with lock for proper installation.

5. Set Function Dip Switches

The purpose of setting the dip switches is to properly configure the electronic

control system to the type of window and window accessories to be controlled.

(See S2 on wire diagram)

1

2

34

5

6

on

off

1 – Must stay set to “on”

2 – Motor Application:

If the motor is installed on a window, set

to “off”

If skylight, set to “on”

3 – Drive motor direction to open (from Step 1)

CW = “off” OR CCW = “on”

4 – Motorized Blinds:

No Blind present = “off”

Blind connected = “on”

5 & 6 – Motorized Locks

No Locks = 5 & 6 both “off”

One Lock = 6 “on” & 5 “off”

Two Locks = 6 “off” & 5 “on”

Note: Dip switch settings must be made with 120 volt supply disconnected.

Did you find what you’re looking for? The Truth Hardware Web site is a great resource for

the latest product and installation information. It’s available at www.truth.com

17

Grey

Green

Grey

Grey

Grey

Green

Green

Green

W

h

i

t

e

W

h

i

t

e

W

h

i

t

e

G

r

e

y

G

r

e

y

R

e

d

B

l

a

c

k

B

l

u

e

B

l

u

e

B

l

u

e

12

10

7

5

4

Motor

Lock 1

Lock 2

R

e

d

B

l

a

c

k

R

e

d

B

l

a

c

k

Screen

Interlock

R

e

d

B

l

a

c

k

B

l

a

c

k

B

l

a

c

k

J

u

m

p

e

r

(

f

a

c

t

o

r

y

i

n

s

t

a

l

l

e

d

)

S

e

e

S

t

e

p

5

+

-

Blind mot or

+

-

S2

S1

12

34

5

6

on

off

H

P

I

"

o

p

e

n

"

J1

R

a

i

n

S

e

n

s

o

r

W

h

i

t

e

W

h

i

t

e

S2

1

2

34

5

6

on

off

1

-

Must stay set to "on"

2

-

Mot or Application:

W

i

n

d

o

w

a

p

p

l

i

c

a

t

i

o

n

=

"

o

f

f

"

S

k

y

l

i

g

h

t

a

p

p

l

i

c

a

t

i

o

n

=

"

o

n

"

3

-

Drive motor direction to Open:

C

W

=

"

o

f

f

"

O

r

C

C

W

=

"

o

n

"

4

-

Motorized Blind:

N

o

B

l

i

n

d

p

r

e

s

e

n

t

=

"

o

f

f

"

B

l

i

n

d

c

o

n

n

e

c

t

e

d

=

"

o

n

"

5&6

-

Mot ori z ed locks:

N

o

l

o

c

k

s

=

5

&

6

b

o

t

h

"

o

f

f

"

O

n

e

l

o

c

k

=

6

"

o

n

"

&

5

"

o

f

f

"

T

w

o

l

o

c

k

s

=

6

"

o

f

f

"

&

5

"

o

n

"

Function Settings for Dip Switches:

Wire Size

(Class 2)

T

o

t

a

l

d

i

s

t

a

n

c

e

f

r

o

m

C

o

n

t

r

o

l

t

o

f

a

r

t

h

e

s

t

m

o

t

o

r

o

r

l

o

c

k

1

8

A

W

G

*

1

4

A

W

G

*

1

2

A

W

G

5

0

f

t

(

1

5

m

)

M

a

x

.

1

0

0

f

t

(

3

0

m

)

M

a

x

.

1

5

0

f

t

(

6

0

m

)

M

a

x

.

S

o

l

i

d

C

o

r

e

W

i

r

e

R

e

c

o

m

m

e

n

d

e

d

.

R

e

f

e

r

t

o

C

l

a

s

s

2

c

o

d

e

s

*

S

e

e

S

t

e

p

4

,

N

o

t

e

1

E

a

r

t

h

G

r

o

u

n

d

f

o

r

a

c

c

e

s

s

o

r

i

e

s

Main Wiring Diagram

O

p

e

n

C

l

o

s

e

S

t

a

t

u

s

+

-

H

P

I

"

c

l

o

s

e

"

G

r

e

y

W

h

i

t

e

R

a

i

n

S

e

n

s

o

r

w

i

r

i

n

g

:

2

2

-

2

s

h

i

e

l

d

e

d

,

t

w

i

s

t

e

d

p

a

i

r

U

p

t

o

5

0

f

t

(

1

5

m

)

M

a

x

.

H

P

I

O

p

e

n

,

H

P

I

C

L

o

s

e

&

S

t

a

t

u

s

w

i

r

i

n

g

:

1

8

-

2

t

w

i

s

t

e

d

p

a

i

r

U

p

t

o

1

5

0

f

t

(

6

0

m

)

M

a

x

.

N

o

t

e

:

T

w

i

s

t

e

d

p

a

i

r

b

e

c

o

m

e

s

m

o

r

e

i

m

p

o

r

t

a

n

t

i

n

n

o

i

s

y

e

n

v

i

r

o

n

m

e

n

t

s

Did you find what you’re looking for? The Truth Hardware Web site is a great resource for

the latest product and installation information. It’s available at www.truth.com

18

6. Connect power wires

Connect supply voltage wires (120 VAC)

to the wire harness and connector as

shown.

Danger: to avoid possible electric shock

power must be shut off at the main breaker

until installation is complete.

7. Plug in and install cover plate

Plug in the ribbon cable from

the wall plate onto control

board (See No. J1 on main wiring

diagram, page 17)

Note: Orientation of plug is critical

to correct operation of wall switch

and LED indicators. See note in

adjacent diagram.

Helpful Hint: The cover plate is only available in one configuration and color.

The cover plate can however, be painted or wall paper can be applied to change

its appearance.

Ribbon Cable has a shiny side

with silver traces and a dull side

with green traces. Install with

dull side (green traces) facing

towards you as shown.

Did you find what you’re looking for? The Truth Hardware Web site is a great resource for

the latest product and installation information. It’s available at www.truth.com

19

8. Apply power

Apply power to the control unit

Note: Upon power-up the window

should

close. (If window is closed,

motor will momentarily hum.)

If the window opens refer to the

window crank direction in step 1 and

dip switch settings in step 5.

• Disconnect power

• Change dip switch 3 on S2

(Refer to step 5.)

• Reapply power

The window should now close.

Note: Do not disconnect power while

the window motor is running.

9. Program remote control*

If optional remote control was purchased, it can now be programmed to the

control unit. Refer to set-up instructions included with the remote control.

*If the installation does not include a remote control, skip to step 10.

10. Establishing operating memory

Press “Open” button.

Please note:

• Upon pressing the open button for the very first time after original

power up, the unit will automatically run through an initialization

cycle, fully opening and closing the window (this may take up to 3

minutes depending on application).

• During this time the switch face plate will display a “Red” LED.

• This cycle is necessary for the unit to establish its operating

parameters which will be stored in permanent memory.

• Once permanent memory is established it is unaffected by loss of

power of any duration.

Did you find what you’re looking for? The Truth Hardware Web site is a great resource for

the latest product and installation information. It’s available at www.truth.com

20

Normal Operation

Note: If the window has manual locks the window must be unlocked before

motorized operation.

Buttons located on wall switch:

To open:

• Press “Open” on either the wall switch or the remote control to fully open

the window. If motorized locks are present they will function as part of

the window by unlocking and locking automatically.

Note: The full open position of a window will vary depending on

operating hardware and sash width. The typical open position is

approximately 70 to 80 degrees. Full opening can be achieved by

pressing the open button repeatedly once the window has stopped.

To close:

• Press “Close” on either the wall switch or the remote control to close the

window.

To stop the window in an intermediate position:

• Press the opposite button while the motor is running (such as pressing

“Close” while the window is opening) will stop the motor. The motor is

restarted by pressing either “Open” or “Close” again.

Status Light Indicator

• During motor operation the status light in the center of the wall plate will

be green to indicate normal operation. (See “Status Codes” on page

28 for more information.)

Status

Light

Open

Window

Or

Skylight

Close

Window

Or

Skylight

Open

Blind

Close

Blind

Did you find what you’re looking for? The Truth Hardware Web site is a great resource for

the latest product and installation information. It’s available at www.truth.com

21

Optional Accessories

Rain Sensor (included)

The sensor will close the window when “beading” moisture is present on the

surface of the rain sensor grid. It will also cause the green LED on the wall plate

to blink (indicating moisture is present). Once the panel is dry, normal operation

is regained.

Note:

• Connect the supplied sensor panel to the grey and green terminals on

Block 5 (see main wiring diagram, page 17). The window can be forced to

open even when the sensor is “wet” but the motor will immediately re-

close the vent.

• There is a 10 second delay from the time the rain sensor senses moisture

to the time the window actually starts to close.)

Rain Sensor Guidelines:

• Install the sensor with "grid" exposed to outside elements where the rain

has a clear, unobstructed path to the rain sensor. Consider prevailing

winds.

• Wire with 22 AWG - 2 conductor shielded, twisted pair 50 ft (15m)

maximum length

Warning: Connect shield to earth ground to reduce interference from

lightning and other electrical devices.

• The sensor can be mounted outside (maximum sensitivity) or inside vent

edge (minimum maintenance)

• Maintenance; Regular cleaning of sensor panel with a mild cleaning agent

is recommended. Dirt or debris can cause the vent to stay closed even

when rain is not present.

Warning:

• When used on skylights, do not route rain sensor wire through the chain

port, damage to wire will be a likely result.

• Do not install the rain sensor if venting of the window or skylight using the HPI

inputs is more important than closing due to rain. The rain sensor overrides all

other inputs. (see HPI, page 22).

Did you find what you’re looking for? The Truth Hardware Web site is a great resource for

the latest product and installation information. It’s available at www.truth.com

22

High Priority Inputs (HPI)

The control unit includes inputs to allow window control from other devices such

as thermostats, home automation systems, security systems, etc. These inputs

are called High Priority Inputs (HPI). There is an input for “Open” and an input

for “Close”. The inputs are designed to be controlled with low voltage dry

contacts (relay).

Note: See main wiring diagram on page 17 for proper connections.

• Input Function - HPI Close:

1. When connected by a continuous contact closure, the window will

close. All other input devices (except for Open & Hold) will be

“locked-out” until the contacts re-open. Do not attempt to open

until window is closed otherwise system may become confused.

2. When connected by momentary contact closure, the window will

close. There will be a minimum delay of 3 seconds before system

will react.

If window is “opening” (in motion) when a momentary “Close” is

received, the motor will stop. In this way a partial open position

can be achieved.

• Input Function - HPI Open:

1. When connected by a continuous contact closure, the window will

open. All other input devices will be “locked-out” until the contacts

re-open. There will be a minimum delay of 3 seconds before

system will react. Do not attempt to close until window is opened

otherwise system may become confused.

2. When connected by momentary contact closure, the window will

open. There will be a minimum delay of 3 seconds before system

will react.

If window is “closing” (in motion) when a momentary “open” is

received, the motor will stop. In this way a partial open position can

be achieved.

Important:

• Voltage supplied by HPI input is: 12 VDC @ 5mA. For

reference only.

• When multiple input sources are used to control a given set of

windows consult the Input Command Priority Table on the Truth

Hardware Web site to insure you receive the proper window

response to multiple input command sources.

Did you find what you’re looking for? The Truth Hardware Web site is a great resource for

the latest product and installation information. It’s available at www.truth.com

23

System Status Feedback

The Sentry II control unit is capable of providing feedback regarding whether

the window is closed or not closed. It will not provide true window position

other than closed.

Note: See main wiring diagram on page 17 for proper connections.

Status output function:

• The status output functions as a relay. When the output is

closed (relay contacts closed), the window is fully closed. When

the output is open (relay contacts open), the window is not fully

closed.

• Feedback output (contact closure) maximum ratings:

Rated Load: 0.50 A at 125VAC, 1 A at 24VDC

Minimum Load: 1mA, 5VDC

Max. operating voltage: 125 VAC, 60 VDC

Max. operating current: 1A

Max. switching capacity: 62.50 VA, 30W

Power Blind Control

The Sentry II control unit is capable of controlling 24 VDC blinds or shades.

Truth Hardware does not supply power blinds or shades. We only supply a

means to conveniently control them with the Sentry II control system. This allows

for a more convenient installation by combining the control of power blinds into

the same control system that opens and closes the windows. Therefore, it is

very important to choose a power blind system that is compatible with the Sentry

II control system.

Please use the following electrical specifications:

• Operating Voltage: 24 VDC

• Maximum current draw: 1 amp (at 24 VDC)

• Power blind system must be range protected with internal limit

switches.

Note: Truth Hardware does not supply the installation instructions for the

installation of the motorized blinds themselves. Please consult instructions

supplied with the blinds for installation.

Did you find what you’re looking for? The Truth Hardware Web site is a great resource for

the latest product and installation information. It’s available at www.truth.com

24

Control unit setup for Power Blind installation:

• Locate DIP switch block on the control unit labeled “S2”. (See main

wiring diagram on page 17.) Set DIP switch #4 to the “on” position.

• Consult blind installation instructions for proper blind motor polarity.

Locate the positive wire to open the motorized blind. Connect it to the

“Grey” terminal on terminal block #12. (See main wiring diagram.)

Note:

• If unable to determine the positive wire to open the motorized blind,

the blind motor can be connected in either orientation. However, if

the blinds open in the opposite direction from the button pressed,

the two wires will need to be reversed.

• When the blinds are used in combination with the HPI “Open”

function, the blinds will open automatically before the window is

opened. This is because this feature is often used for smoke

evacuation when connected to a smoke alarm.

The following companies can provide information on blinds or shades that are

compatible with the Sentry II Motor System. Be sure to ask for the

“Motivator” series made by Verosol. Try these Verosol distributors:

OEM Shades Inc. Shades Unlimited

700 First Ave. 545 Brooklyn Road

Ford City PA 16226 Mount Tabor VT 05739

724-763-3600 802-293-2478

www.oemshades.com

www.skylightshades.com

Trouble Shooting

Common Problems

Note: Additional Technical assistance can be found by logging onto:

truth.com/technicalsupport

Motor does not fit the operator

• Check to be sure the operator was manufactured by Truth Hardware

Motor does not run

• Check to make sure power is on

• Check to make sure that either the screen interlock is connected or

installed properly. (See page 13.)

Did you find what you’re looking for? The Truth Hardware Web site is a great resource for

the latest product and installation information. It’s available at www.truth.com

25

• Check to make sure the jumper is installed across the two grey terminals

on block 10. (See main wiring diagram on page 17.)

Motor is not straight on my window

• Check to be sure the correct mounting hole is used in the mounting

bracket. (See step 4 on page 12.)

Window closes for unknown reason

• Check to make sure the rain sensor is clean – debris or bird droppings can

activate the rain sensor. Clean with a mild soap.

• The motor system may have closed the windows due to a power outage.

Normal operation is to close the windows when the power comes back on.

The window will not open

• If the window is equipped with manual sash locks make sure they are

unlocked.

• Check to be sure the window is not sealed closed against the weather

stripping. Some paints and varnishes will stick to weather stripping. If this

happens, apply a thin film of automotive finish wax to the finished window

surface.

The motor will not respond from the wall switch

• Verify the connector on the back of the switch is connected properly to the

control unit. See step 4 on page 16.

Window closes when “Open” button is pushed (and visa versa)

• The motor drive direction is incorrect and needs to be reversed. Change

setting of DIP switch #3 - See step 5 on page 16.

Window does not open fully

• The motor system is programmed to only open a window or skylight to

70% of full opening. This is done to protect the hardware from repeated

high stresses. Full opening can be achieved by pressing the open button

repeatedly once the window has stopped.

The window or skylight will not open more than a couple of inches

• The control system needs to be re-initialized. Follow “System Reset”

procedure below.

When bench testing the motor the motor will not stop

• This is normal operation. The control unit is looking for a current rise

caused by a motor stall to turn the motor off.

Window does not fully close

• This is usually caused by a motor system that is connected backwards.

To correct:

o Turn the power off;

o On switch block S2 reverse the position of switch 3 (see main

wiring diagram on page 17);

o Turn power back on;

o Motor system will automatically run through a reset the first time the

Did you find what you’re looking for? The Truth Hardware Web site is a great resource for

the latest product and installation information. It’s available at www.truth.com

26

open or close button is pushed.

Motor system is not functioning as expected

• Interrupting the power to the control unit for a short period of time

(approximately 30 seconds) will clear some operating errors. When power

is re-applied the unit should close automatically. (Allow window to fully

close before giving the motor system an open of close command.) Normal

function should be restored.

System Reset

There are times when the motor system operating characteristics can change.

This can occur for a number of reasons. A couple of examples are if the

motor has hit an obstruction or the manual hardware requires cleaning or

service. The motor system is designed to recognize unusually high torque

situations during operation and then stop short of that area on subsequent

operations to protect the motor system and window hardware from damage.

If this occurs, the cause of the high torque situation must first be identified

and removed. A qualified window service technician may be required. Once

the cause has been identified and removed, the window system needs to be

re-initialized to restore full range of motion. Follow the “system reset” options

below.

There are two different types of resets: Partial and Total. A partial systems

reset will restore normal operation under almost all circumstances and is the

easiest to initiate. There are three ways a partial systems reset can be

initiated. Power should be cycled off for 30 seconds and back on before

attemping any of the reset methods.

• With the window closed, simultaneously press both the window and

blind “close” buttons on the wall switch. (See page 20)

• By initiating 3 cycles of open then close (within 3 seconds) via the HPI

(See HPI information on page 22)

• First turn power off for 30 seconds then reapply. Then set the remote

to the appropriate “Unit Code” and simultaneously press and hold the

“Unit” & “Mode” keys down for 10 seconds.

Therm

C

F

Motor

Blind

Unit

Set

Unit

Mode

Open

Close

To “re-initialize” the system: press and hold

these buttons until the “Motor” indicator

flashes.

If the operational issue is not resolved with a

partial reset as described above a total system

reset may be needed.

Did you find what you’re looking for? The Truth Hardware Web site is a great resource for

the latest product and installation information. It’s available at www.truth.com

27

Total System Reset

1. Turn power off.

2. Change all dip switches to “off” (See S2 on main wiring diagram on page

17)

3. Turn power back on for 30 seconds

4. Turn power off

5. Change dip switches back to proper settings.

6. Turn power back on

7. Push “Open” button on wall switch to open window

Service

Truth Hardware has made every effort to make all pertinent information available

to you through this instruction manual and our web site. However, if you

encounter a problem or question you can not resolve to please call 1-800-324-

4487 to speak to one of our hardware technicians or send an email to:

Before contacting Truth Hardware please be aware that:

• Complete product and troubleshooting information is available on our web

site at: www.truth.com/technicalsupport

• A qualified electrician is required to resolve most electrical issues

• Contact a qualified window service technician through your window dealer

to resolve window or hardware related issues.

• Truth Hardware is a window and patio door hardware manufacturer. Truth

Hardware is not the manufacturer of your windows.

• Truth Hardware does not have field service technicians. If you encounter

a problem or question you can not resolve to please call 1-800-324-4487

to speak to one of our hardware technicians or send an email describing

the problem to: [email protected].

• Replacement window hardware is available through the window

manufacturer or through on of our authorized distributors. Consult the

Truth Hardware web site at www.truth.com

for the nearest distributor.

Did you find what you’re looking for? The Truth Hardware Web site is a great resource for

the latest product and installation information. It’s available at www.truth.com

28

Status Codes

During setup and operation the status light on the wall plate will provide

information regarding system function. The following list will help explain the

different conditions indicated:

Flashing Red:

1. Upon initial power-up - This indicates that the dip switches have not been

set correctly. See step 5 on page 16.

2. During motor operation – Indicates that the motor has run into an

obstruction or that the window hardware requires service. This occurs

when the load on the motor exceeds normal operating parameters.

Solid Red:

1. Motor not running

• Check to be sure jumper is installed. (See block 10 on main wiring

diagram.)

• Check to make sure the screen interlock is connected correctly (if

required. (See step 6 on page 13 and main wiring diagram on page

17.)

• Check motor connections.

2. During motor operation – The motor is running through initialization to

learn the range of motion. This is normal operation. The red light will go

out once the initialization cycle is completed successfully.

Solid Green:

Indicates normal motor operation. The light will stay green only while the

motor is running.

Flashing Green:

During set-up: Indicates “learn” mode during remote control set-up. Occurs

after pressing “S1”. (See Installation Instructions supplied with Remote

Control.)

During normal operation:

Indicates the rain sensor has been activated. The

light will flash green only while the window is closing.

Refer to Truth Hardware’s web site for additional troubleshooting information:

truth.com. Look for Technical support. Also check out Tech note #12 in the

product catalog section.

Did you find what you’re looking for? The Truth Hardware Web site is a great resource for

the latest product and installation information. It’s available at www.truth.com

29

Control Box Cut-Out Template

Note: Control box orientation can be rotated to either a horizontal or vertical

position to suit installation.

Regulatory Compliance

United States of America

Federal Communications Commission (FCC)

Unintentional emitter per FCC Part 15

Note: This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions may cause harmful

interference to radio communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

o Reorient or relocate the receiving antenna.

o Increase the separation between the equipment and receiver.

o Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected.

o Consult the dealer or an experienced radio/TV technician for help.

Warning: Changes or modifications not expressly approved by Truth Hardware could void the FCC

compliance and negate your authority to operate the product.

FCC Declaration of Conformity

According to 47 CFR, Parts 15.107 and 15.109 Class B

Responsible party: Truth Hardware, 700 West Bridge St., Owatonna, MN 55060

www.truth.com

or 1-800-324-4487

Product: Sentry II Hand Held Remote (43.53)

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1)

This device may not cause harmful interference, and (2) this device must accept any interference received

including interferences that may cause undesired operation.

Canada

Industry Canada (IC)

Unintentional emitter per ICES-003

This class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme á la norme NMB-003 du Canada.

Operation is subject to the following two conditions: (1) this device may not cause interference, and (2) this

device must accept any interference, including interference that may cause undesired operation of the

device.

Europe

European Community EMC Directive (CE)

Compliance with these directives implies conformity to the following

European Norms or Regulations:

Emissions Immunity

ETSI EN 300-220-1 v1.3.1 (2000-09) ETSI EN 301 489-3 v1.2.1 (2000-08)

ETSI EN 300-220-3 v1.1.1 (2000-09) EN 55014-2: 1997

ETSI EN 301 489-3 v1.2.1 (2000-08)

EN 55014-1: 1997

CONFORMS TO ANSI/UL STD 325; CERTIFIED TO CAN/CSA STD C22.2 NO. 68