#241

Guidance for Industry

Small Entity Compliance Guide

What You Need to Know About the FDA Regulation:

Current Good Manufacturing Practice,

Hazard Analysis, and Risk-Based

Preventive Controls for Food for Animals

(21 CFR Part 507)

Submit comments on this guidance at any time. Submit electronic comments to

http://www.regulations.gov. Submit written comments to the Division of Dockets Management

(HFA-305), Food and Drug Administration, 5630 Fishers Lane, Rm. 1061, Rockville, MD

20852. All comments should be identified with the Docket No: FDA-2011-N-0922 listed in the

notice of availability that publishes in the Federal Register.

Additional copies of this guidance document may be requested from the Policy and Regulations

Staff (HFV-6), Center for Veterinary Medicine, Food and Drug Administration, 7519 Standish

Place, Rockville, MD 20855, and may be viewed on the Internet at either

http://www.fda.gov/AnimalVeterinary/default.htm or http://www.regulations.gov.

U.S. Department of Health and Human Services

Food and Drug Administration

Center for Veterinary Medicine

October 2016

Contains Nonbinding Recommendations

2

Table of Contents

I. INTRODUCTION .............................................................................................................. 4

II. OVERVIEW OF THE RULE ............................................................................................. 5

A. Key Requirements ........................................................................................................ 5

B. Who Must Comply With the Rule? .............................................................................. 5

C. Definitions .................................................................................................................... 6

D. Who Is Exempt From the Requirements for Hazard Analysis and Risk-Based

Preventive Controls for Animal Food or Subject to Modified Requirements? ...................... 7

E. When Do I Have to Comply With the Rule? ................................................................ 9

III. WHAT ON-FARM LOW-RISK ACTIVITIES BY SMALL OR VERY SMALL

BUSINESSES ARE EXEMPT FROM HAZARD ANALYSIS AND PREVENTIVE

CONTROLS? ............................................................................................................................ 10

A. On-Farm Packing or Holding of Animal Food ........................................................... 10

B. On-Farm Manufacturing/Processing .......................................................................... 11

IV. INFORMATION FOR QUALIFIED FACILITIES ......................................................... 12

A. How Can I Tell if My Business is a Qualified Facility? ............................................ 12

B. How Do I Tell FDA That My Business is a Qualified Facility? ................................ 12

C. What Other Information Must I Provide FDA? .......................................................... 13

D. When Must I Tell FDA That My Business is a Qualified Facility? ........................... 13

E. Withdrawal of a Qualified Facility Exemption .......................................................... 14

V. CURRENT GOOD MANUFACTURING PRACTICE (CGMP) .................................... 14

A. Personnel .................................................................................................................... 14

B. Plant and Grounds ...................................................................................................... 15

C. Sanitation .................................................................................................................... 16

D. Water Supply and Plumbing ....................................................................................... 17

E. Equipment and Utensils .............................................................................................. 18

F. Plant Operations—Management................................................................................. 19

G. Plant Operations—Raw Materials and Other Ingredients .......................................... 20

H. Plant Operations—General ......................................................................................... 21

I. Holding and Distribution ................................................................................................ 21

J. Holding and Distribution of Human Food By-Products for Use as Animal Food ......... 22

VI. HAZARD ANALYSIS AND RISK-BASED PREVENTIVE CONTROLS ................... 23

A. Hazard Analysis .......................................................................................................... 23

1. What categories of hazards must you consider? ..................................................... 23

2. What must your hazard evaluation include? ........................................................... 23

B. Preventive Controls .................................................................................................... 24

C. Oversight and Management of Preventive Controls................................................... 26

D. Circumstances When a Preventive Control is Not Required ...................................... 27

E. Supply-Chain Program for Manufacturing/Processing Facilities ............................... 28

1. Requirements .......................................................................................................... 29

2. Exceptions ............................................................................................................... 30

F. Compliance Dates for the Requirements of the Supply−Chain Program ................... 30

Contains Nonbinding Recommendations

3

G. Education and Training .............................................................................................. 30

H. Reanalysis of Your Food Safety Plan ......................................................................... 31

VII. DEFINITIONS ............................................................................................................... 31

Contains Nonbinding Recommendations

4

Guidance for Industry

Small Entity Compliance Guide

What You Need to Know About the FDA Regulation:

Current Good Manufacturing Practice, Hazard Analysis, and

Risk-Based Preventive Controls for Food for Animals

(21 CFR Part 507)

This guidance represents the current thinking of the Food and Drug Administration (FDA or

Agency) on this topic. It does not establish any rights for any person and is not binding on FDA

or the public. You can use an alternative approach if it satisfies the requirements of the

applicable statutes and regulations. To discuss an alternative approach, contact the FDA staff

responsible for this guidance as listed on the title page.

I. INTRODUCTION

The Food Safety Modernization Act of 2011 (FSMA) directs the Food and Drug Administration

(FDA) as the food regulatory agency of the U.S. Department of Health and Human Services to

better protect public health by, among other things, adopting a modern, preventive, and risk-

based approach to food safety. On September 17, 2015, FDA published the final rule Current

Good Manufacturing Practice, Hazard Analysis, and Risk-Based Preventive Controls for Food

for Animals (PCAF or the rule) (80 FR 56173). FDA has prepared this Small Entity Compliance

Guide in accordance with section 212 of the Small Business Regulatory Enforcement Fairness

Act (Pub. Law 104-121). The intent of this guide is to inform domestic and foreign animal food

facilities about the PCAF regulations and enable them to better understand the requirements of

the rule. It contains important information that may affect your facility.

The regulation creates new current good manufacturing practice (CGMP) requirements for

animal food facilities. In addition, it creates new requirements for certain animal food facilities

to establish and implement risk-based preventive controls. The regulations are found at Title 21

of the Code of Federal Regulations part 507 (21 CFR part 507). The rule became effective on

November 16, 2015, but compliance dates are staggered – see section II. E “When Do I Have to

Comply with the Rule?”

In general, FDA guidance documents do not establish legally enforceable responsibilities.

Instead, guidances describe the Agency’s current thinking on a topic and should be viewed only

as recommendations, unless specific regulatory or statutory requirements are cited. The use of

the word should in Agency guidances means that something is suggested or recommended, but

not required.

Contains Nonbinding Recommendations

5

II. OVERVIEW OF THE RULE

A. Key Requirements

Current Good Manufacturing Practice requirements (21 CFR part 507 subpart B) apply to all

facilities unless an exemption applies under 21 CFR 507.5.

Unless an exemption applies (21 CFR 507.5), facilities must establish and implement a food

safety system that includes a hazard analysis and implementation of risk-based preventive

controls for those hazards the facility identifies as requiring a preventive control (21 CFR 507.33

and 507.34).

The rule requires a written food safety plan (21 CFR 507.31). The written plan must be prepared

by (or its preparation overseen by) one or more “preventive controls qualified individuals” (21

CFR 507.31(b)) (see section VII. “Definitions”) and must include the following (21 CFR

507.31(c)):

• A hazard analysis

• Preventive controls

• A risk-based supply chain program, if appropriate

• A recall plan, if there is a hazard requiring a preventive control identified for an animal

food

• Monitoring procedures

• Corrective action procedures

• Verification procedures

Receiving facilities must have a risk-based supply chain program for those raw materials and

other ingredients for which an identified hazard has been controlled before receipt (a supply-

chain-applied control) (21 CFR part 507, subpart E). The risk-based supply-chain program is

flexible and has separate compliance dates (see section II. E. of this guidance).

B. Who Must Comply With the Rule?

The requirements of this rule apply to foreign and domestic establishments that are required to

register with FDA as food facilities under section 415 of the Federal Food, Drug, and Cosmetic

Act, (FD&C Act) because they manufacture, process, pack, or hold food for animal consumption

in the U.S. There are exemptions from the rule or modified requirements and these are listed in

section II.D of this guidance in table 2.

Contains Nonbinding Recommendations

6

C. Definitions

The PCAF rule uses a number of terms in very specific ways. A full list of these terms appears

in this Guidance in section VII. “Definitions.” Table 1 lists some of the key terms.

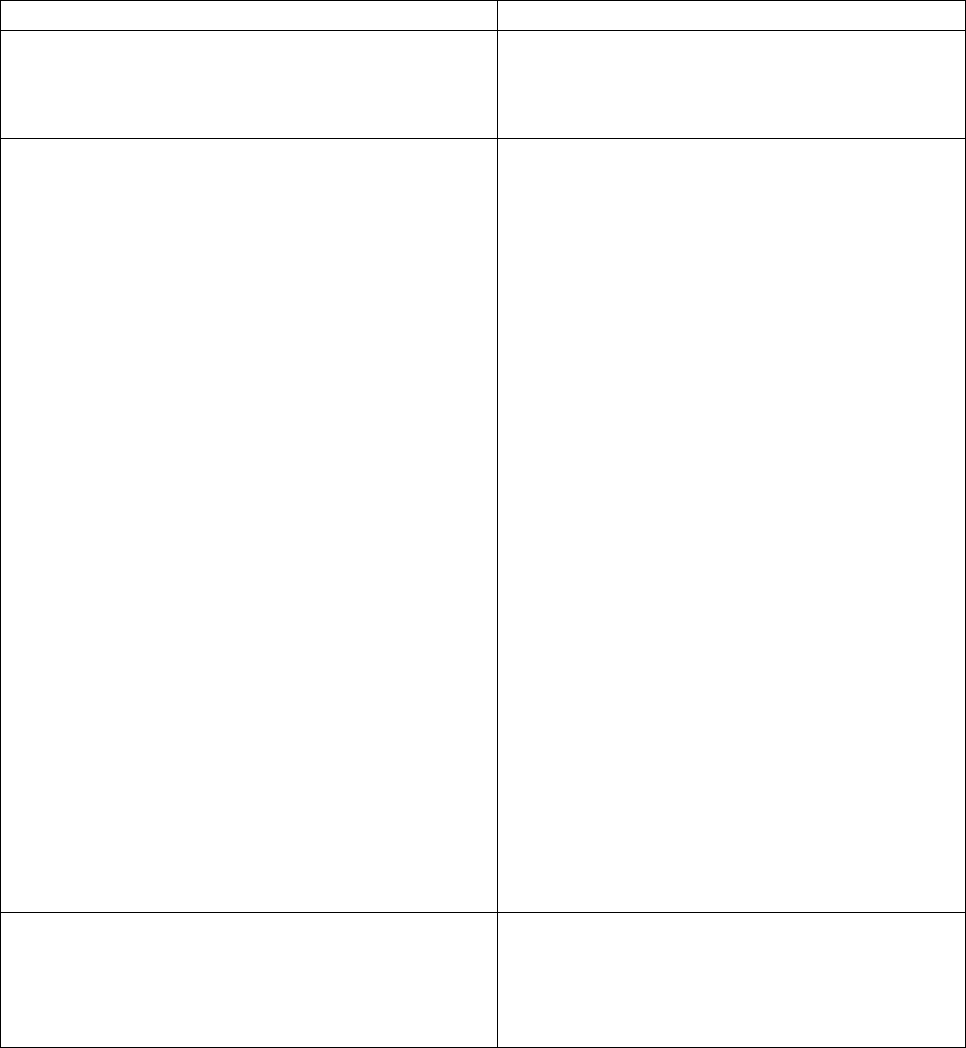

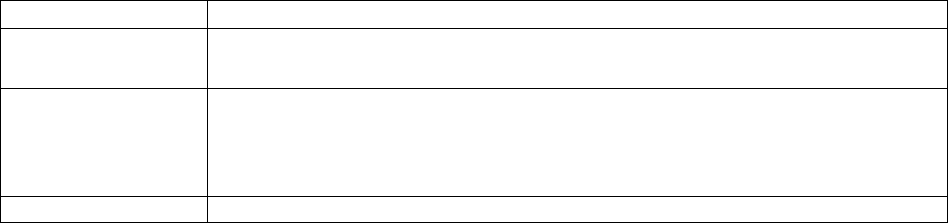

Table 1—Key Terms Used in Part 507

Term

Definition

Animal Food

Food for animals other than man and includes pet food, animal feed,

and raw materials and ingredients

Facility

A domestic facility or a foreign facility that is required to register

under section 415 of the FD&C Act, in accordance with the

requirements of 21 CFR part 1, subpart H

Hazard

Any biological, chemical (including radiological), or physical agent

that has the potential to cause illness or injury in humans or animals.

Hazard requiring a preventive

control

A known or reasonably foreseeable hazard for which a person

knowledgeable about the safe manufacturing, processing, packing,

or holding of animal food would, based on the outcome of a hazard

analysis (which includes an assessment of the severity of the illness

or injury to humans or animals if the hazard were to occur and the

probability that the hazard will occur in the absence of preventive

controls), establish one or more preventive controls to significantly

minimize or prevent the hazard in an animal food and components to

manage those controls (such as monitoring, corrections or corrective

actions, verification, and records) as appropriate to the animal food,

the facility, and the nature of the preventive control and its role in

the facility’s food safety system.

Known or reasonably foreseeable

hazard

A biological, chemical (including radiological), or physical hazard

that is known to be, or has the potential to be, associated with the

facility or the animal food.

Manufacturing/Processing

Making animal food from one or more ingredients, or synthesizing,

preparing, treating, modifying or manipulating animal food,

including food crops or ingredients. (See section VII. “Definitions”

for examples).

Preventive controls

Those risk-based, reasonably appropriate procedures, practices, and

processes that a person knowledgeable about the safe manufacturing,

processing, packing, or holding of animal food would employ to

significantly minimize or prevent the hazards identified under the

hazard analysis that are consistent with the current scientific

understanding of safe food manufacturing, processing, packing, or

holding at the time of the analysis.

Contains Nonbinding Recommendations

7

D. Who Is Exempt From the Requirements for Hazard Analysis and Risk-Based

Preventive Controls for Animal Food or Subject to Modified Requirements?

Table 2 contains information for establishments on exemptions or modified requirements for part

507.

Table 2—Exemptions and Modified Requirements for Part 507

Exemption or Modified Requirement

Conditions

Establishments that are not required to register with

FDA under section 415 of the FD&C Act are exempt

from 21 CFR part 507 (21 CFR 507.5(a))

Farms conducting activities on produce covered

by the Produce Safety Rule will be required to

comply with that rule (Title 21 Code of Federal

Regulations part 117 (21 CFR part 117)

Qualified Facilities are exempt from 21 CFR part

507 subparts C and E (21 CFR 507.7(d)) and are:

Very small businesses (including any subsidiaries or

affiliates) averaging less than $2,500,000 (adjusted

for inflation) -- in both sales of animal food plus the

market value of animal food that is manufactured,

processed, packed, or held without sale (e.g. held for

a fee or supplied to a farm without sale), per year

during the 3-year period preceding the current

calendar year.

OR

A facility to which both of the following apply:

• During the 3-year period preceding the applicable

calendar year, the average annual monetary value

of the food manufactured, processed, packed, or

held at the facility that was sold directly to

consumers, retailers, or restaurants (within the

same state or Indian reservation or within 275

miles of the facility) was less than the monetary

value of food sold by the facility (including sales

by any subsidiary or affiliate) to all other

purchasers; and

• The average annual monetary value of all food

sold during the 3-year period preceding the

applicable calendar year was less than $500,000

To be eligible for modified requirements, a

qualified facility is required to notify FDA about

its qualified facility status; and that it is either:

1. Addressing identified hazards through

preventive controls and monitoring the

preventive controls; or

2. Complying with applicable non-Federal food

safety regulations and notifying consumers of

the name and complete business address of

the facility where the animal food was

manufactured or processed.

3. A qualified facility must submit these

notifications to FDA during the same two year

time frame that the facility is required to

update its facility registration (21 CFR 507.7)

An otherwise Qualified Facility that does NOT

notify FDA is subject to the requirements for 21

CFR part 507

The qualified facility exemption can be withdrawn

in the event of a foodborne illness outbreak. See

21 CFR part 507 subpart D--Withdrawal of a

Qualified Facility Exemption

Low-risk, on-farm activities performed by small

businesses (less than 500 full-time equivalent

employees) or very small businesses (as defined in

the rule) (21 CFR 507.5(e) and (f)) are exempt from

21 CFR part 507 subparts C and E

For specific information on which activities are

covered, see section III of this guidance

Contains Nonbinding Recommendations

8

Exemption or Modified Requirement

Conditions

Activities that are subject to the “low-acid canned

food” requirements (21 CFR 500.23 and part 113) are

exempt from 21 CFR part 507 subparts C and E (21

CFR 507.5(b))

The exemption applies only with respect to

microbiological hazards regulated under 21 CFR

part 113 and the facility must be in compliance

with part 113 (21 CFR 507.5(b)(1) and (b)(2))

Activities of a facility that are subject to Standards

for Produce Safety, section 419 of the FD&C Act (21

CFR 507.5(c))

See FDA’s Produce Safety Rule (21 CFR part

112) for a description of these activities

Establishments that only store raw agricultural

commodities -- other than fruits and vegetables --

intended for further distribution or processing (21

CFR 507.5(g)) are exempt from 21 CFR part 507

subparts C and E

Storage of raw agricultural commodities that are

fruits and vegetables is not exempt

Current good manufacturing practice requirements

(21 CFR part 507 subpart B) do not apply to

establishments that are solely engaged in:

1.

T

he holding and/or transportation of one or more

raw agricultural commodities;

2.

H

ulling, shelling, drying, packing, and/or holding

nuts and hulls; or

3.

G

inning of cotton

(

See 21 CFR 507.5(h))

There can be no manufacturing or processing such

as grinding shells or roasting nuts or extracting oil

from cottonseed

Facilities solely engaged in the storage of unexposed

packaged animal food that does not require

time/temperature control for pathogens (21 CFR

507.10(a))

Subparts C and E of 21 CFR part 507 do not apply

Facilities solely engaged in the storage of unexposed

packaged animal food that does require

time/temperature control for pathogens (21 CFR

507.10(b))

Subparts C and E of 21 CFR part 507 do not apply

except for modified requirements in 21 CFR

507.51 to establish and implement temperature

controls, monitor the temperature controls, correct

any problems, calibrate temperature monitoring

equipment, and review and maintain records

Holding and distribution of human food by-products

for use as animal food (21 CFR 507.12)

For the human food by-products for use as animal

food, the by-product is subject only to the

requirements of 21 CFR 507.28 as long as the by-

product does not undergo further manufacturing

or processing at the human food facility, the

human food facility is in compliance with 21 CFR

part 117 subpart B; or, for the off-farm packing

and holding of produce, in compliance with 21

CFR 117.8; and the facility is in compliance with

all applicable human food safety requirements of

the FD&C Act and implementing regulations.

Contains Nonbinding Recommendations

9

E. When Do I Have to Comply With the Rule?

Facilities have different compliance dates based on business size. Table 3 lists the compliance

dates for the CGMP requirements in subpart B and the preventive controls requirements in

subpart C of 21 CFR part 507. Table 4 lists the compliance dates for the supply-chain program

in subpart E of 21 CFR part 507.

Table 3—Compliance Dates for Part 507

Business Size

Current Good Manufacturing

Practice Compliance Date

Preventive Controls

Compliance Date

Business other than small and very

small

September 19, 2016

September 18, 2017

Small businesses, i.e., a business

with fewer than 500 full-time

equivalent employees

September 18, 2017

September 17, 2018

Qualified facilities (including very

small businesses) as defined

above

September 17, 2018

September 17, 2019, except for

records to support its status as a

very small business is January

1, 2017

Table 4—Compliance Dates for the Requirements of the Supply-Chain Program (Subpart E)

Situation

Compliance Date

A receiving facility is a small business and its

supplier will be subject to the CGMPs, but not the

preventive control requirements, of the animal food

preventive controls rule

6 months after the receiving facility’s supplier of

that raw material or other ingredient is required

to comply with the CGMP requirements of this

rule

A receiving facility is a small business and its

supplier is subject to the animal food preventive

controls rule

The later of: September 17, 2018 or 6 months

after the receiving facility’s supplier of that raw

material or other ingredient is required to comply

with this rule

A receiving facility is not a small business or a very

small business and its supplier will be subject to

CGMPs, but not the preventive control

requirements, of the animal food preventive controls

rule

6 months after the receiving facility’s supplier of

that raw material or other ingredient is required

to comply with the CGMP requirements of this

rule

A receiving facility is not a small business or a very

small business and its supplier will be subject to the

animal food preventive controls rule

The later of: September 18, 2017 or 6 months

after the receiving facility’s supplier of that raw

material or other ingredient is required to comply

with the applicable rule

Contains Nonbinding Recommendations

10

III. WHAT ON-FARM LOW-RISK ACTIVITIES BY SMALL OR VERY SMALL

BUSINESSES ARE EXEMPT FROM HAZARD ANALYSIS AND PREVENTIVE

CONTROLS?

Certain manufacturing, processing, packing, and holding activities are not subject to the

requirements for hazard analysis and risk-based preventive controls and supply-chain program

when they are conducted on-farm by small or very small businesses, if these are the only

activities they conduct that would be subject to the requirements for hazard analysis and risk-

based preventive controls. The exemption only applies to the low-risk activity/animal food

combinations listed in the regulation. In addition, the requirements for a very small business also

would not apply to very small on-farm businesses conducting only these low-risk, on-farm

manufacturing, processing, packing, and holding activities. Following are the exemptions for

on-farm packing and holding of animal food and the exemptions for on-farm manufacturing/

processing of animal food.

A. On-Farm Packing or Holding of Animal Food

The requirements for hazard analysis and risk-based preventive controls and supply-chain

program do not apply to on-farm packing or holding of animal food by a small or very small

business if the packing and holding activities are limited to packing (or re-packing) (including

weighing or conveying incidental to packing or re-packing); sorting, culling, or grading

incidental to packing or storing; and storing (ambient, cold and controlled atmosphere) of (21

CFR 507.5(e)):

• Roughage products—e.g., alfalfa meal, entire plant meal, stem meal, pomace, and pulp

• Plant protein meals—e.g., algae, coconut (copra), guar, and peanut

• Grain by-products and processed grain products—e.g., bran, flour, germ meal, grits,

groats, hominy feed, malt sprouts, middlings, pearled grain, polished grain, brewers

grain, distillers grain, and gluten meal

• Oilseed products—e.g., oil and meal of safflower, soybean, or sunflower

• Molasses—e.g., processed sugar cane, sugar beets, and citrus

• Animal protein meals—e.g., blood, feather, meat, meat and bone, and marine (e.g., crab,

fish, and shrimp)

• Milk products—e.g., casein, cheese rind, and lactalbumin

• Animal tissue-derived products—e.g., fat

• Vitamins, minerals, and concentrates

• Processing aids—e.g., enzymes, preservatives, and stabilizers

Contains Nonbinding Recommendations

11

• Any other processed animal food that does not require time/temperature control for safety

B. On-Farm Manufacturing/Processing

The requirements for hazard analysis and risk-based preventive controls and supply-chain

program do not apply to on-farm manufacturing/processing of animal food by a small or very

small business if the only manufacturing/processing activities that the business conducts consist

of the following low-risk manufacturing/processing activity/animal food combinations (21 CFR

507.5(f)):

• Chopping or shredding hay;

• Cracking, crimping, flaking, pearling, peeling, shelling, or wafering—grain (e.g., barley,

sorghum, corn, oats, rice, rye, and wheat), or oilseed (e.g., beans, canola, cottonseed,

linseed, soybeans, and sunflowers);

• Crushing, dry rolling, grinding, milling, pulverizing—grain, oilseed, grain by-products

and processed grain products, oilseed products, hay, ensiled material, culled fruits and

vegetables, roughage (e.g., cobs, hulls, husks, and straws, or roughage products);

• Ensiling (including chopping, shredding, mixing, storing, or fermenting), i.e., making

silage or haylage from forage ( e.g., sorghum (milo), corn (maize), alfalfa, and grass),

grain, culled fruits and vegetables, or roughage;

• Extracting (mechanical) or wet rolling grain, oilseed, brewers grain by-products, or

distillers grain by-products;

• Labeling roughage products, plant protein meals, grain by-products and processed grain

products, oilseed products, molasses, animal protein meals, milk products, animal tissue-

derived products, vitamins, minerals, concentrates, processing aids, finished animal food,

including animal food ready for consumption, or any other processed animal food that

does not require time/temperature control for safety; and

• Packaging roughage products, plant protein meals, grain by-products and processed grain

products, oilseed products, molasses, animal protein meals, milk products, animal tissue-

derived products, vitamins, minerals, concentrates, processing aids, finished animal food,

including animal food ready for consumption, or any other processed animal food that

does not require time/temperature control for safety.

Contains Nonbinding Recommendations

12

IV. INFORMATION FOR QUALIFIED FACILITIES

A. How Can I Tell if My Business is a Qualified Facility?

To be a qualified facility (see definitions in 21 CFR 507.3 and table 2 in section II.D of this

guidance), a business must either be:

• A very small business (a business, including any subsidiaries and affiliates, averaging

less than $2,500,000, adjusted for inflation, per year, during the 3-year period preceding

the applicable calendar year in sales of animal food plus the market value of animal food

manufactured, processed, packed, or held without sale (e.g., held for a fee or supplied to a

farm without sale)), or

• A facility to which both of the following apply:

o During the 3-year period preceding the applicable calendar year, the average

annual monetary value of the food manufactured, processed, packed or held at

such facility that is sold directly to qualified end-users (consumers, or local

restaurants and retail food establishments not more than 275 miles from the

facility) during such period exceeded the average annual monetary value of the

food sold by such facility (including sales by any subsidiary or affiliate) to all

other purchasers; and

o The average annual monetary value of all food sold during the 3-year period

preceding the applicable calendar year was less than $500,000, adjusted for

inflation.

In determining whether a facility satisfies the definition of qualified facility, the baseline year for

calculating the adjustment for inflation is 2011 (21 CFR 507.7(a)(1)).

B. How Do I Tell FDA That My Business is a Qualified Facility?

• The attestation can be submitted to FDA in one of two ways:

o Electronically — Go to http://www.fda.gov/furls and follow the instructions. FDA

encourages electronic submission.

o Mail — You must use Form FDA 3942b. Send the completed paper Form FDA

3942b to the U.S. Food and Drug Administration (HFS-681), 5001 Campus

Drive, College Park, MD 20740. We recommend that you submit a paper copy

only if your facility does not have reasonable access to the Internet. To obtain a

copy of this form:

Download it from

http://www.fda.gov/Food/GuidanceRegulation/FoodFacilityRegistration/Q

ualifiedFacilityAttestation/default.htm, or

Contains Nonbinding Recommendations

13

Write to the U.S. Food and Drug Administration (HFS-681), 5001

Campus Drive, College Park, MD 20740 or

Request a copy by phone at 1-800-216-7331 or 301-575-0156

C. What Other Information Must I Provide FDA?

• In the attestation you provide FDA, you must include the following:

o You have identified potential hazards associated with the animal food being

produced, are implementing preventive controls to address the hazards, and are

monitoring the performance of the preventive controls to ensure that such controls

are effective (21 CFR 507.7(a)(2)(i)); or

o You are in compliance with State, local, county, tribal, or other applicable non-

Federal food safety law, including relevant laws and regulations of foreign

countries. This attestation may be based on licenses, inspection reports,

certificates, permits, credentials, certification by an appropriate agency (such as a

State department of agriculture), or other evidence of oversight (21 CFR

507.7(a)(2)(ii)).

D. When Must I Tell FDA That My Business is a Qualified Facility?

The attestation verifying that your business is a qualified facility must be submitted to FDA

initially (21 CFR 507.7(c)(2)(i)) —

• By December 16, 2019, for a facility that begins manufacturing, processing, packing, or

holding animal food before September 17, 2019

• Before beginning operations, for a facility that begins manufacturing, processing,

packing, or holding animal food after September 17, 2019; or

Beginning in 2020, your attestation must be submitted to FDA every 2 years during the period

beginning on October 1 and ending on December 31 (21 CFR 507.7(c)(2)(ii)).

The determination of whether a facility satisfies the definition of qualified facility must be made

annually no later than July 1 of each calendar year (21 CFR 507.7(c)(1)). When the status of a

facility changes from “qualified facility” to “not a qualified facility” based on the annual

determination:

• The facility must notify FDA of that change in status using Form FDA 3942b by July 31

of the applicable calendar year (21 CFR 507.7(c)(3)), and

Contains Nonbinding Recommendations

14

• The facility must comply with the requirements for hazard analysis and preventive

controls no later than December 31 of the applicable year, unless otherwise agreed to by

FDA and the facility (21 CFR 507.7(d)).

You must maintain the records you relied upon to support the attestations. These records are

subject to the record keeping requirements of the rule in 21 CFR part 507 subpart F (21 CFR

507.7(f)).

E. Withdrawal of a Qualified Facility Exemption

FDA may withdraw a qualified facility exemption —

• In the event of an active investigation of a foodborne illness outbreak that is directly

linked to the qualified facility (21 CFR 507.60(a)(1)); or

• If FDA determines that it is necessary to protect the public (human or animal) health and

prevent or mitigate a foodborne illness outbreak based on conditions or conduct

associated with the qualified facility that are material to the safety of the animal food

manufactured, processed, packed, or held at such facility (21 CFR 507.60(a)(2)).

Before FDA issues an order to withdraw a qualified facility exemption, FDA —

• May consider one or more other actions to protect the public (human or animal) health or

mitigate a foodborne illness outbreak, including a warning letter, recall, administrative

detention, suspension of registration, refusal of animal food offered for import, seizure,

and injunction (21 CFR 507.60(b)(1));

• Must notify the owner, operator, or agent in charge of the facility, in writing, of

circumstances that may lead FDA to withdraw the exemption, and provide an opportunity

for the owner, operator, or agent in charge of the facility to respond in writing, within 15

calendar days of the date of receipt of the notification, to FDA's notification (21 CFR

507.60(b)(2)); and

• Must consider the actions taken by the facility to address the circumstances that may lead

FDA to withdraw the exemption (21 CFR 507.60(b)(3)).

V. CURRENT GOOD MANUFACTURING PRACTICE (CGMP)

A. Personnel

The management of the establishment must take reasonable measures and precautions to ensure

that all persons working in direct contact with animal food, animal food-contact surfaces, and

animal food-packaging materials conform to hygienic practices necessary to protect against the

contamination of animal food (21 CFR 507.14), including:

Contains Nonbinding Recommendations

15

• Maintaining adequate personal cleanliness;

• Washing hands thoroughly in an adequate hand-washing facility as necessary and

appropriate to protect against contamination;

• Removing or securing jewelry and other objects that might fall into animal food,

equipment, or containers;

• Storing clothing or other personal belongings in areas other than where animal food is

exposed or where equipment or utensils are cleaned; and

• Taking any other necessary precautions to protect against the contamination of animal

food, animal food-contact surfaces, or animal food-packaging materials

B. Plant and Grounds

Grounds — The grounds around an animal food plant under the control of the management of

the establishment must be kept in a condition that will protect against the contamination of

animal food. Maintenance of grounds must include (21 CFR 507.17(a)):

• Properly storing equipment, removing litter and waste, and cutting weeds or grass within

the immediate vicinity of the plant that may constitute an attractant, breeding place, or

harborage for pests;

• Maintaining driveways, yards, and parking lots so that they do not constitute a source of

contamination in areas where animal food is exposed;

• Adequately draining areas that may contribute contamination to animal food by seepage,

foot-borne filth, or providing a breeding place for pests; and

• Treating and disposing of waste so that it does not become a source of contamination in

areas where animal food is exposed.

Plant construction and design — The plant must be suitable in size, construction, and design to

facilitate cleaning, maintenance, and pest control to reduce the potential for contamination of

animal food, animal food-contact surfaces, and animal food-packaging materials, i.e., the plant

must (21 CFR 507.17(b)):

• Provide adequate space between equipment, walls, and stored materials to permit

employees to perform their duties and to allow cleaning and maintenance of equipment;

• Be constructed in a manner such that drip or condensate from fixtures, ducts, and pipes

does not serve as a source of contamination;

Contains Nonbinding Recommendations

16

• Provide adequate ventilation (mechanical or natural) where necessary and appropriate to

minimize vapors (e.g., steam) and fumes in areas where they may contaminate animal

food, and in a manner that minimizes the potential for contaminating animal food;

• Provide adequate lighting in hand-washing areas, toilet rooms, areas where animal food is

received, manufactured, processed, packed, or held, and areas where equipment or

utensils are cleaned; and

• Provide shatter-resistant light bulbs, fixtures, and skylights, or other glass items

suspended over exposed animal food in any step of preparation, to protect against the

contamination of animal food in case of glass breakage.

Animal food stored outdoors in bulk — The plant must protect animal food stored outdoors in

bulk from contamination by any effective means, including (21 CFR 507.17(c)):

• Using protective coverings where necessary and appropriate;

• Controlling areas over and around the bulk animal food to eliminate harborage for pests;

and

• Checking on a regular basis for pests, pest infestation, and product condition related to

safety of the animal food.

C. Sanitation

• Buildings, structures, fixtures, and other physical facilities of the plant must be kept clean

and in good repair to prevent animal food from becoming adulterated (21 CFR

507.19(a)).

• Animal food contact and non-contact surfaces of utensils and equipment must be cleaned

and maintained and utensils and equipment stored as necessary to protect against the

contamination of animal food, animal food-contact surfaces, or animal food-packaging

materials. When necessary, equipment must be disassembled for thorough cleaning. In

addition (21 CFR 507.19(b)):

o When animal food-contact surfaces used for manufacturing, processing, packing,

or holding animal food are wet-cleaned, the surfaces must, when necessary, be

thoroughly dried before subsequent use; and

o In wet processing of animal food, when cleaning and sanitizing are necessary to

protect against the introduction of undesirable microorganisms, all animal food-

contact surfaces must be cleaned and sanitized before use and after any

interruption during which the animal food-contact surfaces may have become

contaminated.

Contains Nonbinding Recommendations

17

• Cleaning compounds and sanitizing agents must be safe and adequate under the

conditions of use (21 CFR 507.19(c)).

• Only the following toxic materials may be used or stored in a plant where animal food is

processed or exposed (21 CFR 507.19(d)(1)) –

o Those required to maintain clean and sanitary conditions;

o Those necessary for use in laboratory testing procedures;

o Those necessary for plant and equipment maintenance and operation; and

o Those necessary for use in the plant's operations.

• Those toxic materials that are allowed to be used or stored in the plant area where animal

food is manufactured, processed, or exposed must be identified, used, and stored in a

manner that protects against contamination of animal food, animal food-contact surfaces,

or animal food-packaging materials (21 CFR 507.19(d)(2));

• Other toxic materials, such as fertilizers and pesticides, must be stored in an area of the

plant where animal food is not manufactured, processed, or exposed (21 CFR

507.19(d)(3));

• Effective measures must be taken to exclude pests from the manufacturing, processing,

packing, and holding areas of a plant and to protect against the contamination of animal

food by pests. The use of pesticides in the plant is permitted only under precautions and

restrictions that will protect against the contamination of animal food, animal food-

contact surfaces, and animal food-packaging materials (21 CFR 507.19(e)); and

• Trash must be conveyed, stored, and disposed of in a way that protects against the

contamination of animal food, animal food-contact surfaces, animal food-packaging

materials, water supplies, and ground surfaces, and minimizes the potential for the trash

to become an attractant and harborage or breeding place for pests (21 CFR 507.19(f)).

D. Water Supply and Plumbing

• Water must be adequate for the operations and must be derived from an adequate source

(21 CFR 507.20(a)(1)).

• Running water at a suitable temperature, and under suitable pressure as needed, must be

provided in all areas where required for (21 CFR 507.20(a)(2)):

o Manufacturing, processing, packing, or holding of animal food;

o Cleaning of equipment, utensils, and animal food-packaging materials; and

Contains Nonbinding Recommendations

18

o Employee hand-washing facilities.

• Water that contacts animal food, animal food-contact surfaces, or animal food-packaging

materials must be safe for its intended use (21 CFR 507.20(a)(3));

• Water may be reused for washing, rinsing, or conveying animal food if it does not

increase the level of contamination of the animal food (21 CFR 507.20(a)(4));

• Plumbing must be designed, installed, and maintained to (21 CFR 507.20(b)):

o Carry adequate quantities of water to required locations throughout the plant;

o Properly convey sewage and liquid disposable waste from the plant;

o Avoid being a source of contamination to animal food, water supplies, equipment, or

utensils, or creating an unsanitary condition;

o Provide adequate floor drainage in all areas where floors are subject to flooding-type

cleaning or where normal operations release or discharge water or other liquid waste

on the floor; and

o Ensure that there is no backflow from, or cross-connection between, piping systems

that discharge waste water or sewage and piping systems that carry water for animal

food or animal food manufacturing.

• Sewage and liquid disposal waste must be disposed of through an adequate sewerage

system or through other adequate means (21 CFR 507.20(c));

• Each plant must provide employees with adequate, readily accessible toilet facilities.

Toilet facilities must be kept clean and must not be a potential source of contamination of

animal food, animal food-contact surfaces, or animal food-packaging materials (21 CFR

507.20(d)); and

• Each plant must provide hand-washing facilities designed to ensure that an employee's

hands are not a potential source of contamination of animal food, animal food-contact

surfaces, or animal food-packaging materials (21 CFR 507.20(e)).

E. Equipment and Utensils

• All plant equipment and utensils used in manufacturing, processing, packing, or holding

animal food, including equipment and utensils that do not come in contact with animal

food, must be designed and constructed of such material and workmanship to be

adequately cleanable, and must be properly maintained (21 CFR 507.22(a)(1));

Contains Nonbinding Recommendations

19

• Equipment and utensils must be designed, constructed, and used appropriately to avoid

the adulteration of animal food with non-food grade lubricants, fuel, metal fragments,

contaminated water, or any other contaminants (21 CFR 507.22(a)(2));

• Equipment must be installed so as to facilitate the cleaning and maintenance of the

equipment and adjacent spaces (21 CFR 507.22(a)(3));

• Animal food-contact surfaces must be:

o Made of materials that withstand the environment of their use and the action of

animal food, and, if applicable, the action of cleaning compounds, cleaning

procedures, and sanitizing agents (21 CFR 507.22(a)(4));

o Made of nontoxic materials;

o Maintained to protect animal food from being contaminated.

• Holding, conveying, manufacturing, and processing systems, including gravimetric,

pneumatic, closed, and automated systems, must be designed, constructed, and

maintained in a way to protect against the contamination of animal food (21 CFR

507.22(b));

• Each freezer and cold storage compartment used to hold animal food must be fitted with

an accurate temperature-measuring device (21 CFR 507.22(c));

• Instruments and controls used for measuring, regulating, or recording temperatures, pH,

a

w

, or other conditions that control or prevent the growth of undesirable microorganisms

in animal food must be accurate, precise, adequately maintained, and adequate in number

for their designated uses (21 CFR 507.22(d)); and

• Compressed air or other gases mechanically introduced into animal food or used to clean

animal food-contact surfaces or equipment must be used in such a way to protect against

the contamination of animal food (21 CFR 507.22(e)).

F. Plant Operations—Management

• Management of the establishment must ensure that (21 CFR 507.25(a)):

o All operations in the manufacturing, processing, packing, and holding of animal food

(including operations directed to receiving, inspecting, transporting, and segregating)

are conducted in accordance with the current good manufacturing practice

requirements of this rule;

o Animal food, including raw materials, other ingredients, or rework is accurately

identified;

Contains Nonbinding Recommendations

20

o Animal food-packaging materials are safe and suitable;

o The overall cleanliness of the plant is under the supervision of one or more competent

individuals assigned responsibility for this function;

o Adequate precautions are taken so that plant operations do not contribute to

contamination of animal food, animal food-contact surfaces, and animal food-

packaging materials;

o Chemical, microbial, or extraneous-material testing procedures are used where

necessary to identify sanitation failures or possible animal food contamination;

o Animal food that has become adulterated is rejected, disposed of, or if appropriate,

treated or processed to eliminate the adulteration. If disposed of, it must be done in a

manner that protects against the contamination of other animal food; and

o All animal food manufacturing, processing, packing, and holding is conducted under

such conditions and controls as are necessary to minimize the potential for the growth

of undesirable microorganisms to protect against the contamination of animal food.

G. Plant Operations—Raw Materials and Other Ingredients

• All raw materials and other ingredients must be examined to ensure that they are suitable

for manufacturing and processing into animal food and must be handled under conditions

that will protect against contamination and minimize deterioration (21 CFR

507.25(b)(1)). In addition:

o Shipping containers (e.g., totes, drums, and tubs) and bulk vehicles holding raw

materials and other ingredients must be examined upon receipt to determine whether

contamination or deterioration of animal food has occurred;

o Raw materials must be cleaned as necessary to minimize contamination;

o Raw materials and other ingredients, including rework, must be stored in containers

designed and constructed in a way that protects against contamination and

deterioration, and held under conditions, e.g., appropriate temperature and relative

humidity, that will minimize the potential for growth of undesirable microorganisms

and prevent the animal food from becoming adulterated.

• Raw materials and other ingredients (21 CFR 507.25(b)(2)) —

o Susceptible to contamination with mycotoxins or other natural toxins must be

evaluated and used in a manner that does not result in animal food that can cause

injury or illness to animals or humans; and

Contains Nonbinding Recommendations

21

o If frozen, must be kept frozen. If thawing is required prior to use, it must be done in a

manner that minimizes the potential for the growth of undesirable microorganisms.

H. Plant Operations—General

• For the purposes of manufacturing, processing, packing, and holding operations, the

following apply (21 CFR 507.25(c)(1)-(8)):

o Animal food must be maintained under conditions, e.g., appropriate temperature and

relative humidity, that will minimize the potential for growth of undesirable

microorganisms and prevent the animal food from becoming adulterated during

manufacturing, processing, packing, and holding;

o Measures taken during manufacturing, processing, packing, and holding of animal

food to significantly minimize or prevent the growth of undesirable microorganisms

(e.g., heat treating, freezing, refrigerating, irradiating, controlling pH, or controlling

water activity (a

w

)) must be adequate to prevent adulteration of animal food;

o Work-in-process and rework must be handled so that it is protected against

contamination and the growth of undesirable microorganisms;

o Steps such as cutting, drying, defatting, grinding, mixing, extruding, pelleting, and

cooling, must be performed in a way that protects against the contamination of animal

food;

o Filling, assembling, packaging, and other operations must be performed in a way that

protects against the contamination of animal food and the growth of undesirable

microorganisms;

o Animal food that relies principally on the control of water activity (a

w

) for preventing

the growth of undesirable microorganisms must be processed to and maintained at a

safe a

w

level;

o Animal food that relies principally on the control of pH for preventing the growth of

undesirable microorganisms must be monitored and maintained at the appropriate pH;

and

o When ice is used in contact with animal food, it must be made from water that is safe

and must be used only if it has been manufactured in accordance with current good

manufacturing practice as outlined in this rule.

I. Holding and Distribution

• Animal food held for distribution must be held under conditions that will protect against

contamination and minimize deterioration, including the following (21 CFR 507.27(a)):

Contains Nonbinding Recommendations

22

o Containers used to hold animal food before distribution must be designed, constructed

of appropriate material, cleaned as necessary, and maintained to protect against the

contamination of animal food; and

o Animal food held for distribution must be held in a way that protects against

contamination from sources such as trash.

• The labeling for the animal food ready for distribution must contain, when applicable,

information and instructions for safely using the animal food for the intended animal

species (21 CFR 507.27(b));

• Shipping containers (e.g., totes, drums, and tubs) and bulk vehicles used to distribute

animal food must be examined prior to use to protect against the contamination of animal

food from the container or vehicle when the facility is responsible for transporting the

animal food itself or arranges with a third party to transport the animal food (21 CFR

507.27(c));

• Animal food returned from distribution must be assessed for animal food safety to

determine the appropriate disposition. Returned animal food must be identified as such

and segregated until assessed (21 CFR 507.27(d)); and

• Unpackaged or bulk animal food must be held in a manner that does not result in unsafe

cross contamination with other animal food (21 CFR 507.27(e)).

J. Holding and Distribution of Human Food By-Products for Use as Animal Food

Human food by-products held for distribution as animal food without additional manufacturing

or processing by the human food processor must be held under conditions that will protect

against contamination, including the following (21 CFR 507.28(a)):

• Containers and equipment used to convey or hold human food by-products for use as

animal food before distribution must be designed, constructed of appropriate material,

cleaned as necessary, and maintained to protect against the contamination of human food

by-products for use as animal food;

• Human food by-products for use as animal food held for distribution must be held in a

way to protect against contamination from sources such as trash; and

• During holding, human food by-products for use as animal food must be accurately

identified.

In addition:

• Labeling that identifies the product by the common or usual name must be affixed to or

accompany human food by-products for use as animal food when distributed (21 CFR

507.28(b)); and

Contains Nonbinding Recommendations

23

• Shipping containers (e.g., totes, drums, and tubs) and bulk vehicles used to distribute

human food by-products for use as animal food must be examined prior to use to protect

against contamination of the human food by-products for use as animal food from the

container or vehicle when the facility is responsible for transporting the human food by-

products for use as animal food itself or arranges with a third party to transport the human

food by-products for use as animal food (21 CFR 507.28(c)).

VI. HAZARD ANALYSIS AND RISK-BASED PREVENTIVE CONTROLS

A. Hazard Analysis

The first step in developing your food safety plan is to conduct a hazard analysis. You must

conduct the hazard analysis to identify and evaluate known or reasonably foreseeable hazards

(hazards that are known to be, or have the potential to be, associated with the facility or the

animal food) for each type of animal food manufactured, processed, packed, or held at your

facility. The identification and evaluation are based on experience, illness data, scientific

reports, and other information. The next step is to determine whether any of the identified

known or reasonably foreseeable hazards require a preventive control (21 CFR 507.33(a)(1)).

These hazards may occur naturally, may happen unintentionally, or may be intentionally

introduced for economic gain. (See 21 CFR 507.33(b)(2).) The hazard analysis must be written,

regardless of its outcome, as part of the written food safety plan (21 CFR 507.33(a)(2)).

1. What categories of hazards must you consider?

There are three categories of hazards--biological, chemical (including radiological), and physical

that you must consider in your hazard analysis (21 CR 507.33(b)(1)). Table 5 lists these

categories with examples of each for animal food.

Table 5—Categories of hazards

Category

Description

Biological hazards

Microbiological hazards such as parasites, environmental pathogens, and other

pathogens (e.g., Salmonella spp. or Listeria monocytogenes)

Chemical (including

Hazards such as pesticide and drug residues, natural toxins (such as mycotoxins),

radiological) hazards decomposition, unapproved food or color additives, and nutrient deficiencies or

toxicities (such as inadequate thiamine in cat food or excessive copper in food

for sheep)

Physical hazards

Hazards such as stones, glass, and metal fragments

2. What must your hazard evaluation include?

Your hazard evaluation must include consideration of the severity of the illness or injury caused

to humans or animals if the identified hazards were to occur and the probability that the hazards

will occur without preventive controls (21 CFR 507.33(c)). The evaluation must consider the

Contains Nonbinding Recommendations

24

effect of various factors on the safety of the finished food for the intended animal (21 CFR

507.33(d)). Table 6 lists these factors.

Table 6—What Factors the Hazard Evaluation Must Consider

Factors to Consider

Description

Formulation of the animal food

Nutrient deficiencies and toxicities (such as lack of

thiamine in cat food or too much copper in sheep food) can

result in illness or injury to animals. Certain ingredients

such as acids and preservatives inhibit growth of, or even

kill, microorganisms of public health significance.

Condition, function, and design of the

facility and equipment

Equipment with close-fitting parts may be difficult to clean

and could allow pathogens to become established.

Equipment with metal-to-metal contact may generate metal

fragments.

Raw materials and other ingredients

Contaminated ingredients can introduce hazards such as

pathogens or chemical toxins (e.g., mycotoxins).

Transportation practices

Failure to adequately clean animal-food contact surfaces of

transportation equipment could result in contamination of

an animal food.

Manufacturing/processing procedures

Improper cooling or holding of certain animal food, such as

pet food, can result in contamination of the animal food

with environmental pathogens.

Packaging and labeling activities

Failure to include on the labeling instructions for safe use

for the intended species could result in unsafe use in a

different species.

Storage and distribution

Some animal food requires refrigerated storage or moisture

controls to maintain safety.

Intended or reasonably foreseeable use

Food for cattle containing copper could be a safety concern

if fed to sheep.

Sanitation, including employee

hygiene

Animal food, such as raw pet food, may be subject to

contamination in an unclean facility, from unclean

equipment, or from poor employee hygiene.

Other relevant factors

Factors which may create hazards, e.g., weather’s effect on

levels of some natural toxins such as mycotoxins.

B. Preventive Controls

Your written food safety plan must identify the preventive controls you have implemented to

ensure that any hazards requiring a preventive control will be significantly minimized or

prevented (21 CFR 507.34(a)). These controls include those at critical control points (CCPs) if

there are any, or controls other than at CCPs as appropriate for animal food safety. Preventive

controls may include any or all of the following (21 CFR 507.34(c)):

• Process controls

• Sanitation controls

Contains Nonbinding Recommendations

25

• Supply-chain controls

• Recall plan.

The types of preventive controls you must use will depend on the facility and the animal food:

• Process controls are procedures, practices, and processes to ensure the control of

operations such as heat processing, acidifying, irradiating, and refrigerating foods. When

applying a process control, you must specify the parameter that is monitored (e.g., the

temperature, the pH of the animal food) and the minimum or maximum value that

ensures control (e.g., a minimum of 375°F (for a heat treatment), a maximum of 41°F (for

refrigerated storage). (See 21 CFR 507.34(c)(1).)

• Sanitation controls are procedures, practices, and processes to ensure that the facility’s

sanitation practices are adequate to significantly minimize or prevent hazards such as

environmental pathogens and biological hazards due to employee handling (21 CFR

507.34(c)(2)). Sanitation controls must address:

o The cleanliness of animal food-contact surfaces, including animal food-contact

surfaces of utensils and equipment;

o Prevention of cross-contamination from insanitary objects and from personnel to

animal food, animal food packaging material, and other animal food-contact surfaces,

and from raw product to processed product; and

o The sanitation controls do not include all sanitation procedures used in the facility,

only those that are used to control a hazard requiring a preventive control.

• Supply-chain controls are activities taken to verify that suppliers that are controlling

hazards are doing so effectively. This will be covered in section VI.E on Supply Chain

Program for Receiving Facilities (21 CFR 507.34(c)(3)).

• A recall plan is required for any animal food with a hazard requiring a preventive control

(21 CFR 507.38). It must be written and must include steps to take and the person

responsible for taking the steps to:

o Notify your direct customers;

o Notify the public, if necessary;

o Check the effectiveness of the recall; and

o Appropriately dispose of the recalled animal food.

Contains Nonbinding Recommendations

26

C. Oversight and Management of Preventive Controls

The PCAF rule provides flexibility in the steps needed to ensure that preventive controls are

effective and to correct problems that may arise. These procedures or management components

are designed to provide assurance that preventive controls are effective and consistently

performed (21 CFR 507.39). Table 7 provides information on these management components

and recordkeeping.

Table 7— Preventive Control Management Components

Management

Components

Explanation

Monitoring

You must have written procedures for monitoring each preventive control,

including how often these procedures are to be performed (21 CFR 507.40)

Corrective actions

and corrections

Procedures taken to identify and correct a problem that occurs during animal food

production. Corrective actions include steps taken when a problem occurs with

implementation of a preventive control, steps taken to reduce the likelihood the

problem will recur, steps taken to evaluate the affected animal food for safety, and

steps taken to prevent it from entering commerce. Corrective actions must be

documented in records. Corrections that don’t include all these steps may be taken

in certain situations, such as for minor problems that don’t affect the safety of the

animal food (21 CFR 507.42)

Verification &

Validation

These are activities to ensure that preventive controls are consistently applied and

effective in controlling the hazards. It is critical to verify that controls are carried

out and, where necessary, to validate with scientific evidence that a control

measure effectively controls an identified hazard. Verification activities include

calibration (or accuracy checks) of process monitoring and verification instruments

(such as thermometers) and reviewing records to verify that monitoring is being

conducted and appropriate corrective actions are taken (if necessary) (21 CFR

507.45 and 507.47)

Product testing and

environmental

monitoring

These are verification activities for implementation and effectiveness of preventive

controls. Environmental monitoring generally would be required if contamination

of a finished animal food with an environmental pathogen is a hazard requiring a

preventive control (21 CFR 507.49)

Contains Nonbinding Recommendations

27

Management

Components

Explanation

Records

Records may be originals, true copies – i.e., reproductions of originals – or

electronic (21 CFR 507.202(a)(1)) and must be made promptly available to an

authorized representative of the Secretary of Health and Human Services (such as

an FDA investigator or State inspector conducting inspections for FDA) (21 CFR

507.200(c)). The following apply to records:

•

R

ecords include your food safety plan itself, i.e., hazard analysis and

preventive controls development; recall plan; and monitoring, corrective action

and verification procedures

• R

ecords include implementation records, i.e., monitoring data, corrective

actions taken, validation documentation, verification activity records, supply-

chain program execution, and personnel training

• Y

our records must include information to identify your plant or facility, the

date when the activity was documented, and product or lot code if applicable

(21 CFR 507.202(b))

• R

ecords must be kept for at least 2 years after the date prepared, or as long as

necessary for those records used to support your status as a qualified facility

(21 CFR 507.208(a))

• Existing records you use to comply with other Federal, State, or local

regulations do not need to be duplicated if they satisfy the record keeping

requirement. Existing records may be supplemented where needed to satisfy

the requirements for part 507 (21 CFR 507.212(a))

D. Circumstances When a Preventive Control is Not Required

If you are a manufacturer/processor, you are not required to implement a preventive control for

an identified hazard if any of the following circumstances apply (21 CFR 507.36):

• You determine and document that the animal food in question could not be consumed

without application of an appropriate control.

• You rely on your customer who is subject to the requirements for hazard analysis and

risk-based preventive controls to ensure that the identified hazard will be significantly

minimized or prevented, and you:

o Disclose in documents accompanying the animal food, in accordance with trade

practice, that the animal food is “not processed to control [identified hazard]”; and,

o Annually obtain from your customer written assurance that the customer has

established and is following procedures (identified in the written assurance) that will

significantly minimize or prevent the identified hazard, unless your customer has

determined that the identified hazard is not a hazard in the animal food intended for

use for a specific animal species and your customer's written assurance provides this

determination, specifying the animal species and why the identified hazard is not a

hazard.

Contains Nonbinding Recommendations

28

• You rely on your customer who is not subject to the requirements for hazard analysis and

risk-based preventive controls (e.g., because the customer is a qualified facility subject to

modified requirements or some other business not subject to the requirements) to provide

assurance the customer is manufacturing, processing, or preparing the animal food in

accordance with applicable animal food safety requirements and you:

o Disclose in documents accompanying the animal food, in accordance with trade

practice, that the animal food is “not processed to control [identified hazard]”, and

o Annually obtain from your customer written assurance that your customer is

manufacturing, processing, or preparing the animal food in accordance with

applicable animal food safety requirements.

• You rely on your customer to provide assurance that the animal food will be processed to

control the identified hazard by an entity in the distribution chain subsequent to the

customer and you:

o Disclose in documents accompanying the animal food, in accordance with trade

practice, that the animal food is “not processed to control [identified hazard]”; and

o Annually obtain from your customer written assurance that your customer:

Will disclose in documents accompanying the animal food, in accordance with

trade practice, that the animal food is “not processed to control [identified

hazard]”; and

Will only sell to another entity that agrees, in writing, that it will:

• Follow identified procedures that will significantly minimize or prevent the

identified hazard – if the entity is covered by hazard analysis and risk-based

preventive controls requirements – or, if it is not so covered, it will

manufacture, process, or prepare the animal food in accordance with

applicable animal food safety requirements; or

• Obtain a similar written assurance from the entity's customer.

• You have established, documented, and implemented a system that ensures control, at a

subsequent distribution step, of the identified hazards in the animal food product you

distribute and you document the implementation of that system.

E. Supply-Chain Program for Manufacturing/Processing Facilities

If a manufacturing/processing facility (i.e., receiving facility) has identified in its raw materials

and ingredients a hazard that requires a preventive control and the receiving facility relies on a

control applied in the supply chain before receipt, the facility must have a supply-chain program

(21 CFR part 507 subpart E). Manufacturing/processing facilities that control all identified

Contains Nonbinding Recommendations

29

hazards with their own preventive controls, or who follow requirements applicable when relying

on a commercial customer to control hazards, do not need to have a supply-chain program for

such animal food.

Animal food facilities subject to the supply-chain program requirements of this rule are

responsible for ensuring that raw materials and other ingredients for their products are received

only from approved suppliers, or — if received on a temporary basis from unapproved suppliers

— ensuring those materials are subject to verification activities before being accepted for use (21

CFR 507.110(d)(1), 507.115(a)(1) and 507.120).

1. Requirements

a. The supply-chain program must be written (21 CFR 507.105(b)) and must include:

• Using suppliers approved by the receiving facility (21 CFR 507.110(a)(1), 507.115(a)(1),

and 507.120);

• Determining appropriate supplier verification activities (including determining the

frequency of conducting the activity) (21 CFR 507.110(a)(2) and 507.125);

• Conducting supplier verification activities (21 CFR 507.110(a)(3), 507.130 and 507.135);

• Documenting supplier verification activities (21 CFR 507.110(a)(4) and 507.175); and

• When applicable, verifying a supply-chain-applied control applied by an entity other than

the receiving facility's supplier and documenting that verification, or obtaining

documentation of an appropriate verification activity from another entity, reviewing and

assessing that documentation, and documenting the review and assessment (21 CFR

507.110(a)(5) and 507.175).

• Other entities in the supply chain, such as a broker or distributor, can conduct supplier

verification activities, but the receiving facility must review and assess the entity’s

documentation verifying control of the hazard and document this review (21 CFR

507.110(a)(5)).

b. Supplier verification activities (21 CFR 507.110(b)(1)-(4)) include:

• Onsite audits;

• Sampling and testing of raw materials or other ingredients;

• Review of the supplier's relevant food safety records; and

• Other appropriate supplier verification activities based on the risk associated with the raw

material or other ingredient and supplier performance.

Contains Nonbinding Recommendations

30

2. Exceptions

• A receiving facility that is an importer, is in compliance with the foreign supplier

verification requirements, and has documentation of verification activities which provide

assurance that the hazards requiring a supply-chain-applied control for a raw material or

other ingredient have been significantly minimized or prevented, does not need to

conduct supplier verification activities for that raw material or other ingredient (21 CFR

507.105(a)(2)).

• The requirements in subpart E do not apply to animal food that is supplied for research or

evaluation use (21 CFR 507.105(a)(3)).

F. Compliance Dates for the Requirements of the Supply−Chain Program

Separate compliance dates have been established for the supply-chain program provisions so that

an animal food facility will not be required to comply with the supply-chain program provisions

before its supplier is required to comply with the PCAF rule or the produce safety rule (if

applicable). See table 4 in section II.E for the compliance dates.

G. Education and Training

Establishments subject to subpart C of this rule must ensure that the individual (preventive

controls qualified individual) who prepares or oversees preparation of their animal food safety

system has completed training in the development and application of risk-based preventive

controls at least equivalent to that received under a standardized curriculum recognized as

adequate by FDA, or is otherwise qualified through job experience to develop and apply an

animal food safety system (21 CFR 507.31 and 507.53(c)(1)).

In addition, each individual (including temporary and seasonal personnel) engaged in (or

supervising) manufacturing, processing, packing, or holding animal food covered by this rule

must:

• Be a qualified individual, i.e., have the education, training, or experience (or a

combination of these) necessary to manufacture, process, pack, or hold safe animal food

as appropriate to the individual's assigned duties (21 CFR 507.4(b)(1)); and

• Receive training in the principles of animal food hygiene and animal food safety,

including the importance of employee health and personal hygiene, as appropriate to the

animal food, the facility and the individual's assigned duties (21 CFR 507.4(b)(2)).

Additional qualifications for supervisory personnel: responsibility for ensuring compliance

with the requirements of this rule must be clearly assigned to supervisory personnel who have

the education, training, or experience (or a combination of these) necessary to supervise

subordinates in the production of safe animal food (21 CFR 507.4(c)).

Contains Nonbinding Recommendations

31

Records documenting required training in the principles of animal food hygiene and animal food

safety must be established and maintained (21 CFR 507.4(d)).

H. Reanalysis of Your Food Safety Plan

You must reanalyze your food safety plan at least once every 3 years (21 CFR 507.50(a)). You

must also conduct a reanalysis whenever:

• A significant change in the activities at your facility creates a potential for a new hazard

or a significant increase in a previously identified hazard (21 CFR 507.50(b)(1));

• You become aware of new information about potential hazards associated with the

animal food (21 CFR 507.50(b)(2));

• It is appropriate after an unanticipated animal food safety problem (21 CFR

507.50(b)(3)); and

• You find that a preventive control(s) or the food safety plan as a whole is ineffective (21

CFR 507.50(b)(4)).

VII. DEFINITIONS

Adequate: That which is needed to achieve the intended purpose in keeping with good public

(human and animal) health practice.

Affiliate: Any facility that controls, is controlled by, or is under common control with another

facility.

Animal food: Food for animals other than man, and includes pet food, animal feed, and raw

materials and ingredients.

Audit: The systematic, independent, and documented examination (through observation,

investigation, records review, discussions with employees of the audited entity, and, as

appropriate, sampling and laboratory analysis) to assess an audited entity's food safety processes

and procedures.

Calendar day: Every day shown on the calendar.

Correction: An action to identify and correct a problem that occurred during the production of

animal food, without other actions associated with a corrective action procedure (such as actions

to reduce the likelihood that the problem will recur, evaluate all affected animal food for safety,

and prevent affected animal food from entering commerce).

Critical control point: A point, step, or procedure in a food process at which control can be

applied and is essential to prevent or eliminate a food safety hazard or reduce such hazard to an

acceptable level.

Contains Nonbinding Recommendations

32

Environmental pathogen: A pathogen capable of surviving and persisting within the

manufacturing, processing, packing, or holding environment such that food for animals may be

contaminated and may result in foodborne illness if that animal food is not treated to

significantly minimize or prevent the environmental pathogen. Examples of environmental